Large-scale industrial fan

A large-scale industrial and fan technology, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, and pump devices, etc., can solve the problems of long fan blade length, lack of support for fan blades, and hidden safety hazards. To achieve the effect of reducing costs, reducing the number of uses, and safety costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

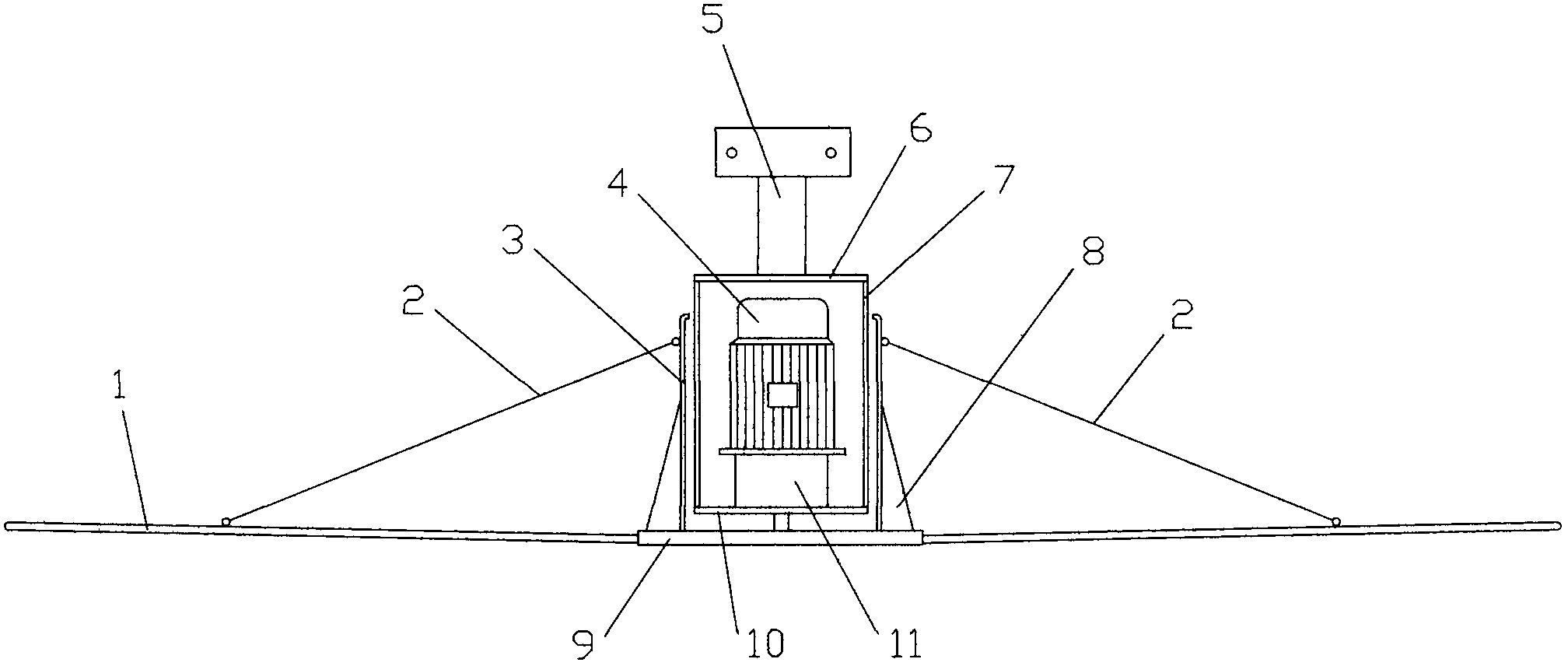

[0018] see figure 1 , the large industrial fan of the present invention includes a motor 4, a plurality of fan blades 1 and a blade fixed disk 9, the working main shaft of the motor 4 is connected to the blade fixed disk 9, and the roots of the plurality of fan blades 1 are connected to the fixed disk 9. The fan blade fixing plate 9 is fixedly connected. When in use, the fan of the present invention is hoisted on the workshop roof or beams.

[0019] In addition, the blade fixed plate 9 is also provided with a traction rope connector 3, and the traction rope connector 3 is respectively connected to the plurality of fan blades 1 by a traction rope 2, and the traction rope 2 is connected to each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com