Absorptive article and manufacturing method thereof

An absorbent and article technology, applied in the field of hygiene products, can solve the problems of increased manufacturing cost, reduced production efficiency, and insufficient softness, and achieve the effects of reducing equipment manufacturing costs, saving elastic materials, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

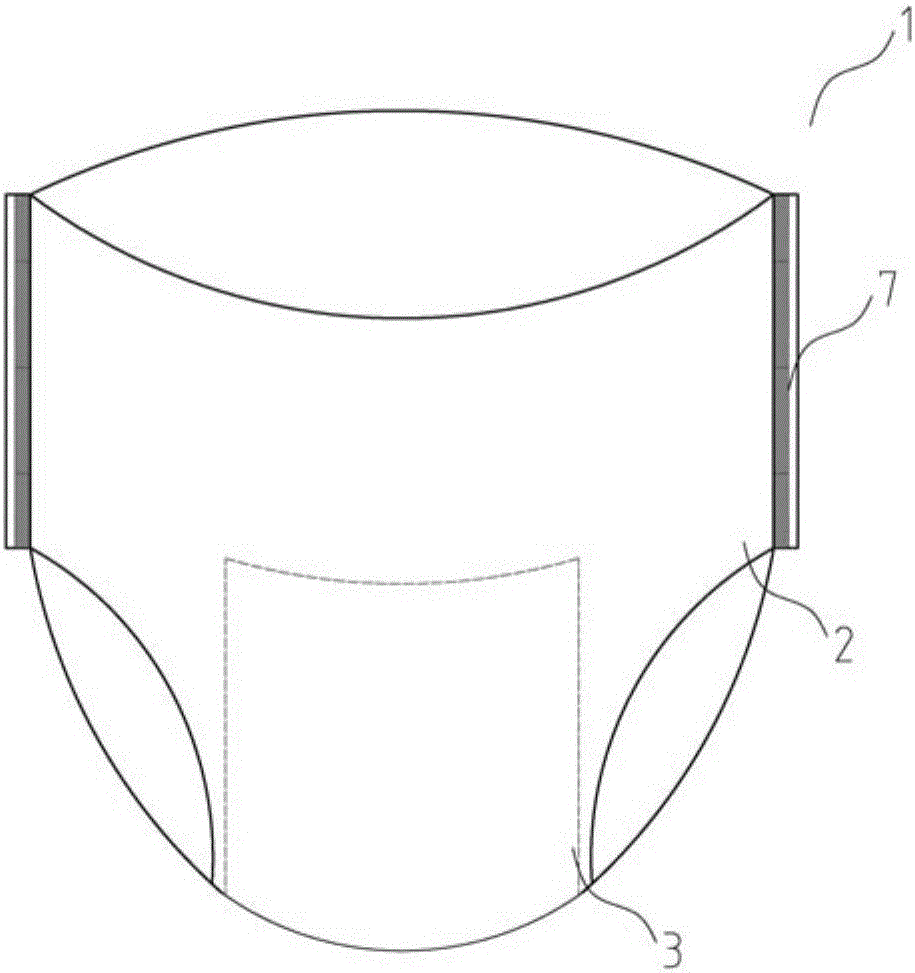

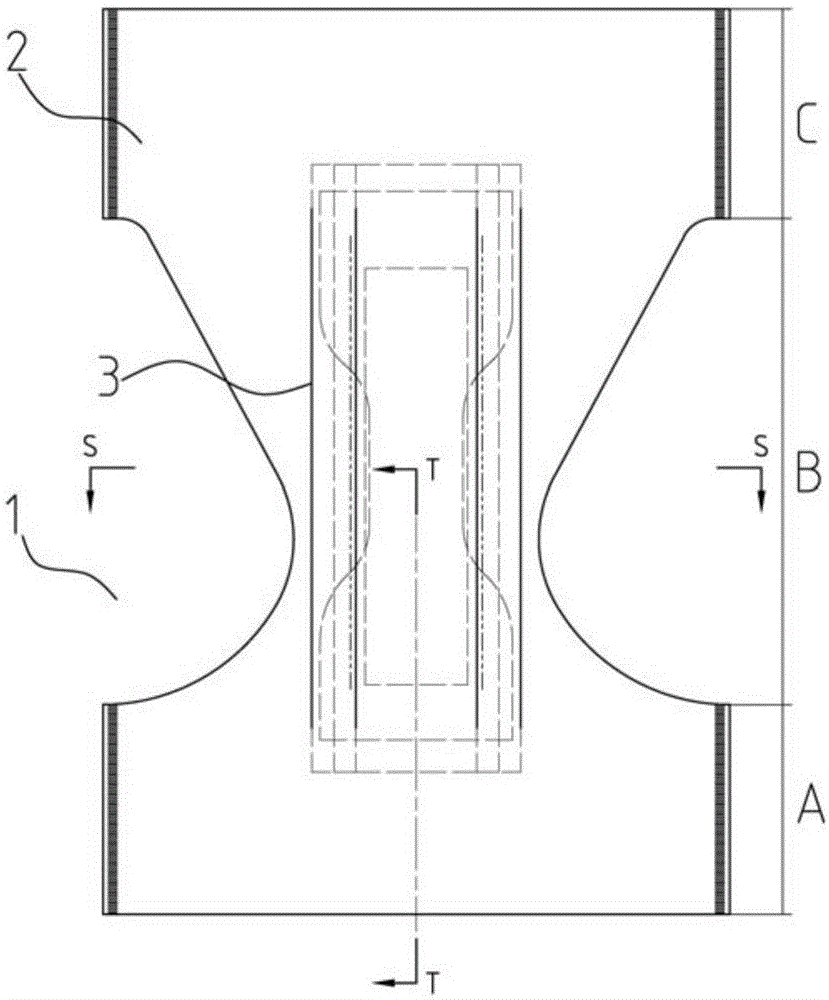

[0028] Such as Figures 1 to 4 An absorbent article 1 shown is divided into an abdominal area A and a back area C centering on a crotch B in the longitudinal direction.

[0029] The absorbent article 1 has an outer cover 2 and an interior 3 .

[0030] The outer cover layer 2 is composed of a sheet material having elastic properties, said outer cover layer 2 is joined at the side edges of the abdomen area and the side edges of the back area to form the absorbent article 1 .

[0031] The outer covering layer 2 has good elastic properties, so the sheet can quickly retract when the external force is removed. Therefore, the outer covering layer 2 made of the above-mentioned sheet material has elastic properties without adding additional elastic materials, thereby eliminating the need for elastic materials and reducing production costs.

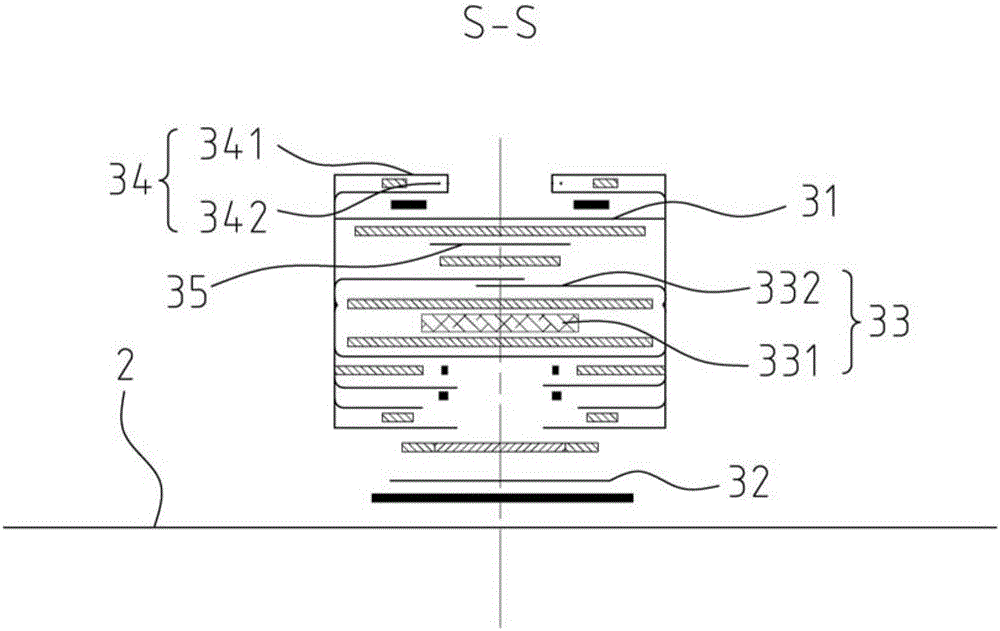

[0032] The interior 3 includes a liquid-permeable front sheet 31 , a liquid-impermeable back sheet 32 , an absorber 33 interposed between the ...

Embodiment 2

[0042] Such as Figures 5 to 7The absorbent article 1 shown is provided with waist elastic members 6 at the front and rear ends of the outer covering layer 2 located in the abdominal region A and the back region C respectively, and the waist elastic members 6 are not in contact with the abdominal region A and the back region B in the lateral direction. The edges of the two sides overlap, and the front and rear ends of the interior 3 are respectively provided with a waist covering sheet 5 extending longitudinally toward the front and rear ends of the outer cladding layer 2, and the waist covering sheet 5 covers the waist elastic member 6 and the front and rear ends of the interior 3 Part; all the other are with embodiment 1.

[0043] Such as Figure 8 As shown, a method for manufacturing an absorbent article, the longitudinal direction of the absorbent article is the process direction, and the transverse direction is the width direction, including the following steps:

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com