Water vapor separator and uniform heating pipe of jig dyeing machine heating system

A heating system and jigger technology, applied in the field of jigger heating system, can solve the problems of uneven dyeing of fabrics, uneven dyeing tank temperature, waste of steam, etc., to solve the problem of not being able to directly heat dyeing and reduce the workload of equipment maintenance , The effect of reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

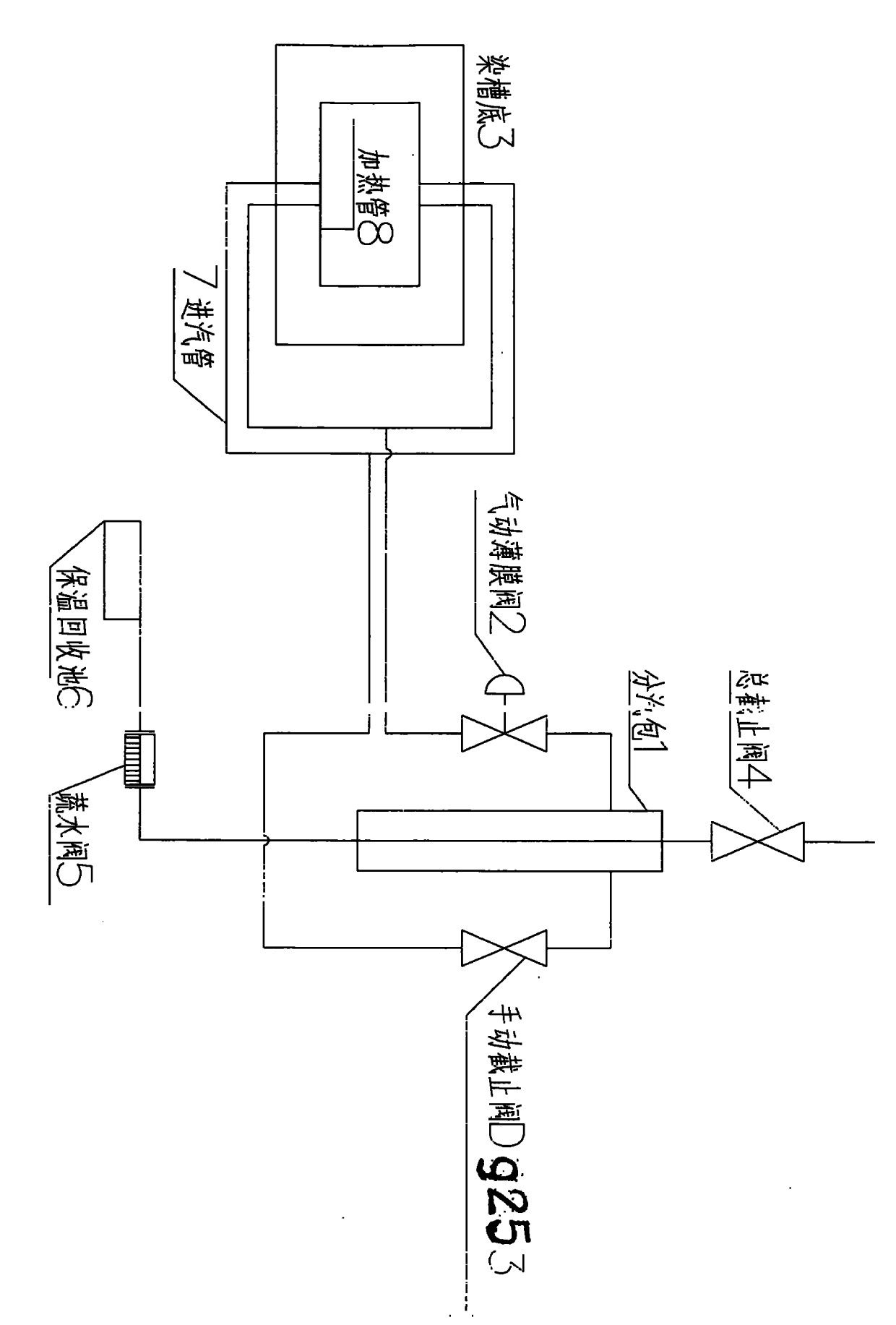

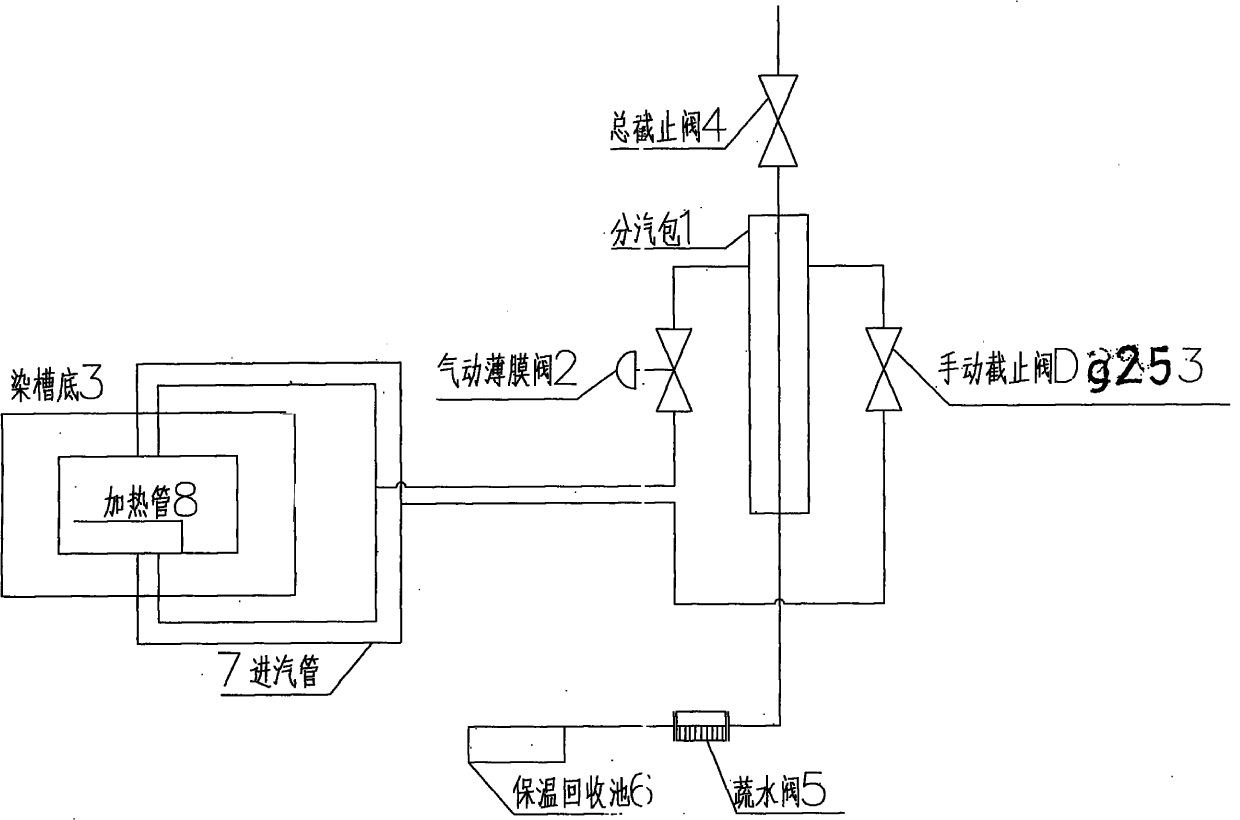

[0007] As shown in the figure, the present invention consists of a steam distribution drum 1, a total cut-off valve 4, a manual valve 3, an automatic pneumatic film valve 2, a steam inlet pipe 7, a heating pipe 8, a dyeing tank bottom 9, a vegetable water valve 5, heat preservation recovery The pool is composed of 6 and so on. The sub-steam drum 1 is composed of elbows, flanges, and pipes. It is assembled with a steam-operated membrane valve 2 and a manual stop valve 3 into automatic 2, manual 3, and valve control. The main stop valve 4 controls the steam source and 5 vegetable and water valves. The hot water is discharged to the thermal insulation recovery pool 6, and the steam inlet pipe 7 is temperature-controlled from the lower part of the dyeing tank 9 through the heating pipe in series.

[0008] The performance and characteristics comparison of the heating system of dyeing jigger

[0009] Dye Jigger Heating System

[0010] At present, most of the heating systems of dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com