Mechanical continuous extraction process for stevioside and continuous extraction unit

A technology of stevioside and extraction process, which is applied in the field of extraction of sweet ingredients of stevia, can solve the problems of low production efficiency, long assembly line, large floor space and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

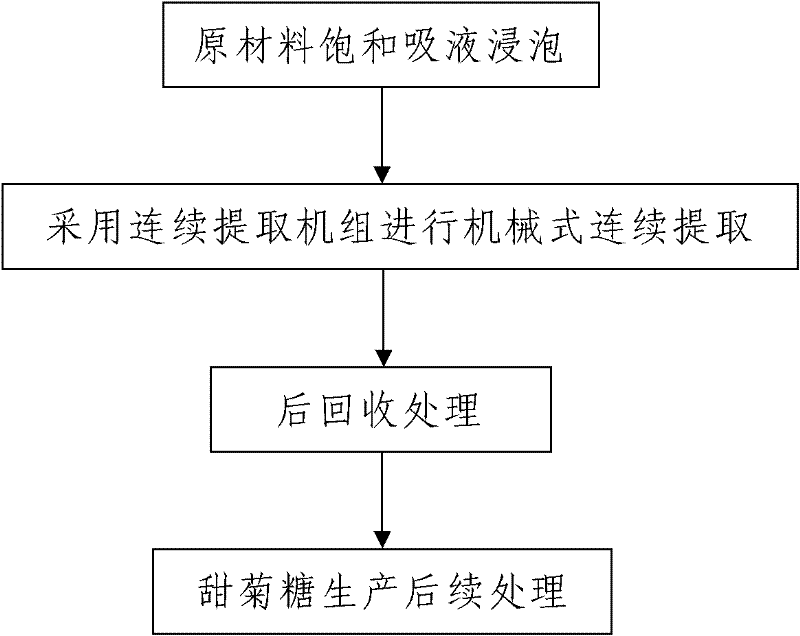

[0110] Such as figure 1 A mechanical continuous extraction process for steviosides shown, comprising the following steps:

[0111] Step 1. Soaking with saturated liquid absorption: Soak the stevia leaves to be treated in a soaking tank or a soaking tank, and make the stevia leaves reach a state of saturated liquid absorption.

[0112] When actually soaking in saturated liquid absorption, the temperature of the water used is room temperature or 40°C to 80°C. That is to say, when soaking in practice, it can be soaked in hot water at 40°C to 80°C (hot water supply equipment is required at this time), or it can be soaked in cold soaking (operated at room temperature). In this embodiment, hot water at a temperature of 60° C. is used for soaking. When actually soaking with saturated liquid absorption, the temperature of the hot water used can be adjusted within the range of 40° C. to 80° C. according to actual specific needs. At the same time, before using the soaking tank to soak...

Embodiment 2

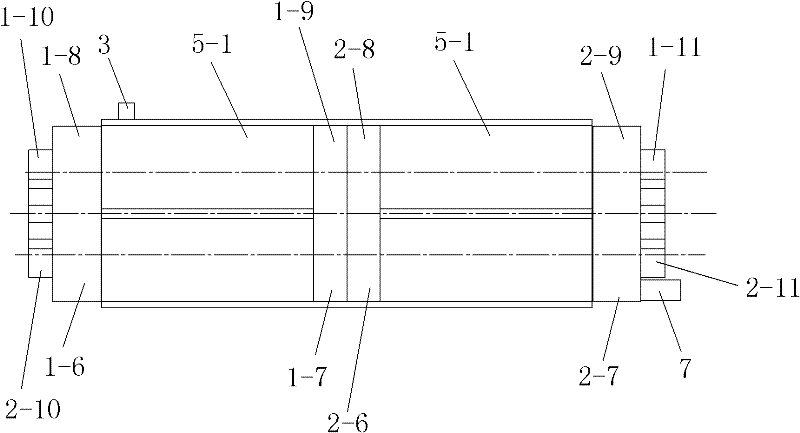

[0164] In this example, the mechanical continuous extraction process of stevioside used is different from that in Example 1 in that: after the residual material obtained in step 204 is discharged through the discharge port 7, it is necessary to use material conveying equipment to remove the residual material The material is sent to the feed port 3 of the continuous extraction unit, and the residual material is repeatedly treated according to the treatment methods described in steps 201 to 204. Moreover, the methods and steps for repeatedly processing the residual materials according to the processing methods described in steps 201 to 204 are the same as the connection extraction methods and steps described in step 2 of embodiment 1.

[0165] Therefore, in the actual extraction process, before feeding, it is determined according to the specific conditions whether to repeat the continuous extraction process for the stevia leaves to be treated. According to the extraction process...

Embodiment 3

[0174] In this example, the mechanical continuous extraction process of stevioside used is different from that in Example 1 in that: after the residual material obtained in step 204 is discharged through the discharge port 7, it is necessary to use material conveying equipment to remove the residual material The material is sent to the feed port 3 of the next continuous extraction unit, and the residual material is repeatedly treated according to the treatment method described in steps 201 to 204.

[0175] In the actual extraction process, before feeding, it is determined according to the specific situation whether to repeat the continuous extraction process of the stevia leaves to be treated. In the extraction process, the residual material discharged through the discharge port 7 is sent to the feed port 3 of the next continuous extraction unit to repeat the continuous extraction process.

[0176] In the actual use process, the number of times of repeated continuous extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com