3300V mining explosion-proof and intrinsic safety type permanent magnet synchronous frequency conversion and speed regulation all-in-one machine

A technology of permanent magnet synchronization and variable frequency speed regulation, which is applied in the direction of electromechanical devices, motor control, AC motor control, etc., can solve the problems of difficulty in guaranteeing the reliability of frequency converters, large volume of frequency converters, and unfavorable technology promotion, etc., to reduce shutdown Peak voltage, volume reduction, volume-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The 3300V mine explosion-proof and intrinsically safe permanent magnet synchronous variable frequency speed regulation integrated machine (hereinafter referred to as the integrated machine) provided by the present invention is a permanent magnet synchronous motor integrated with a frequency converter, with a power of 525-1600kW and a power supply voltage of 3300V, which is the world's largest. The first high-voltage and high-power inverter integrated machine.

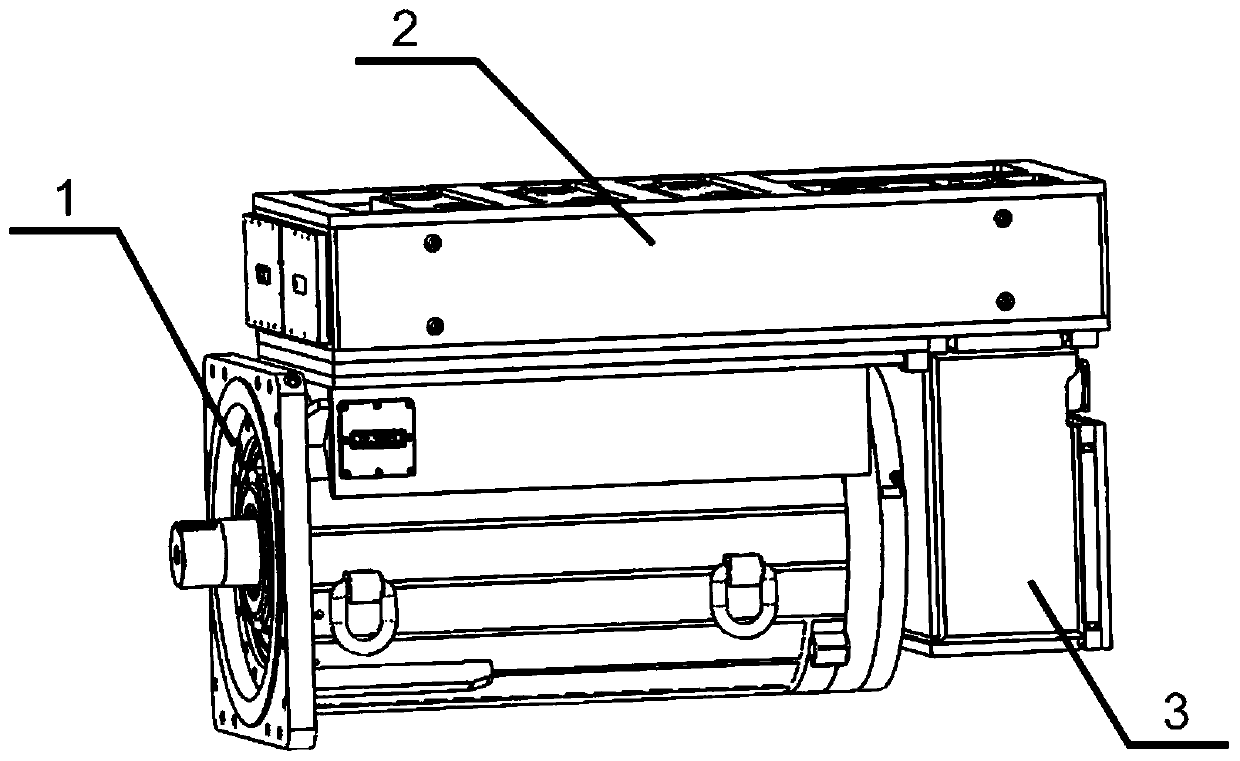

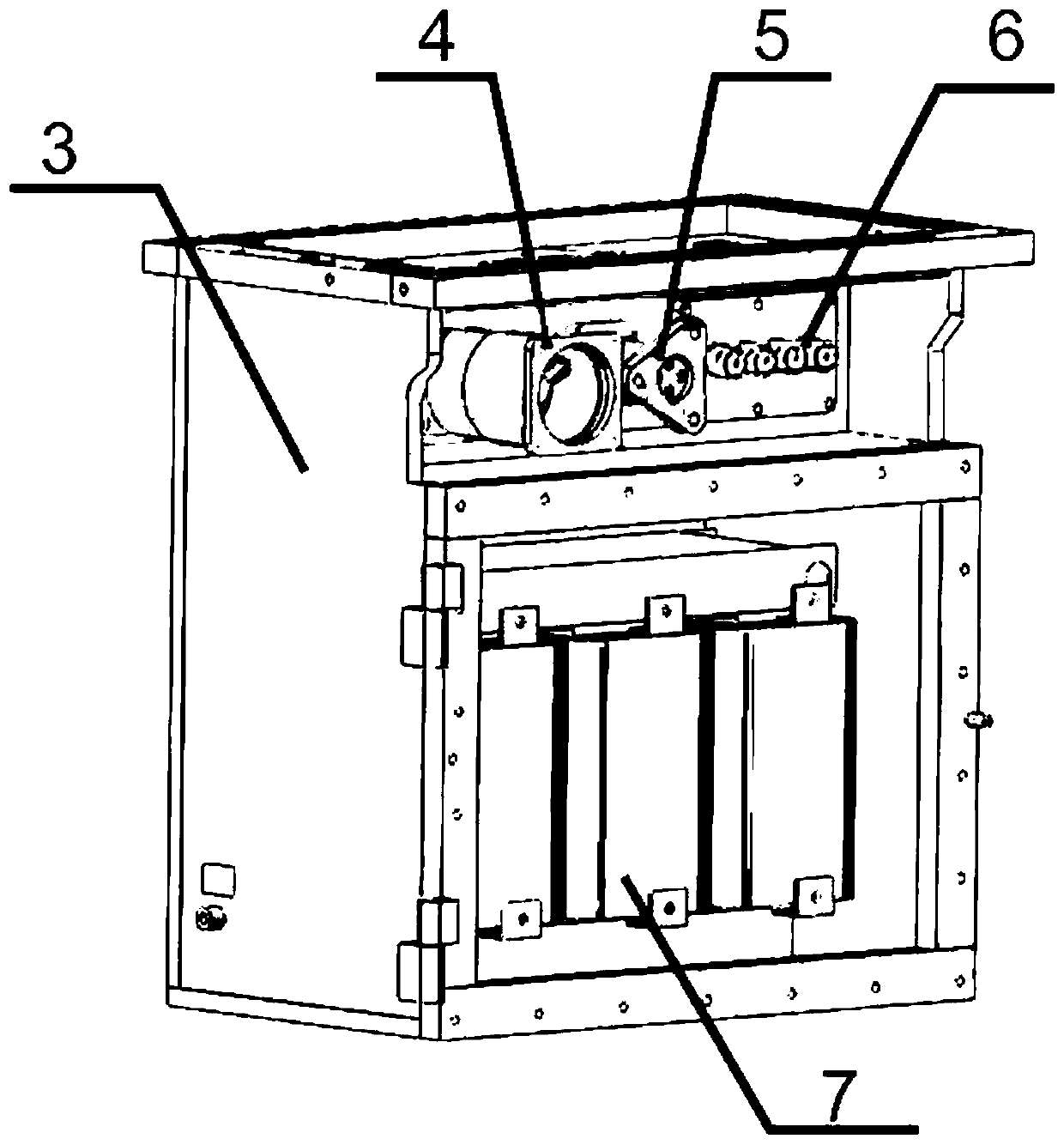

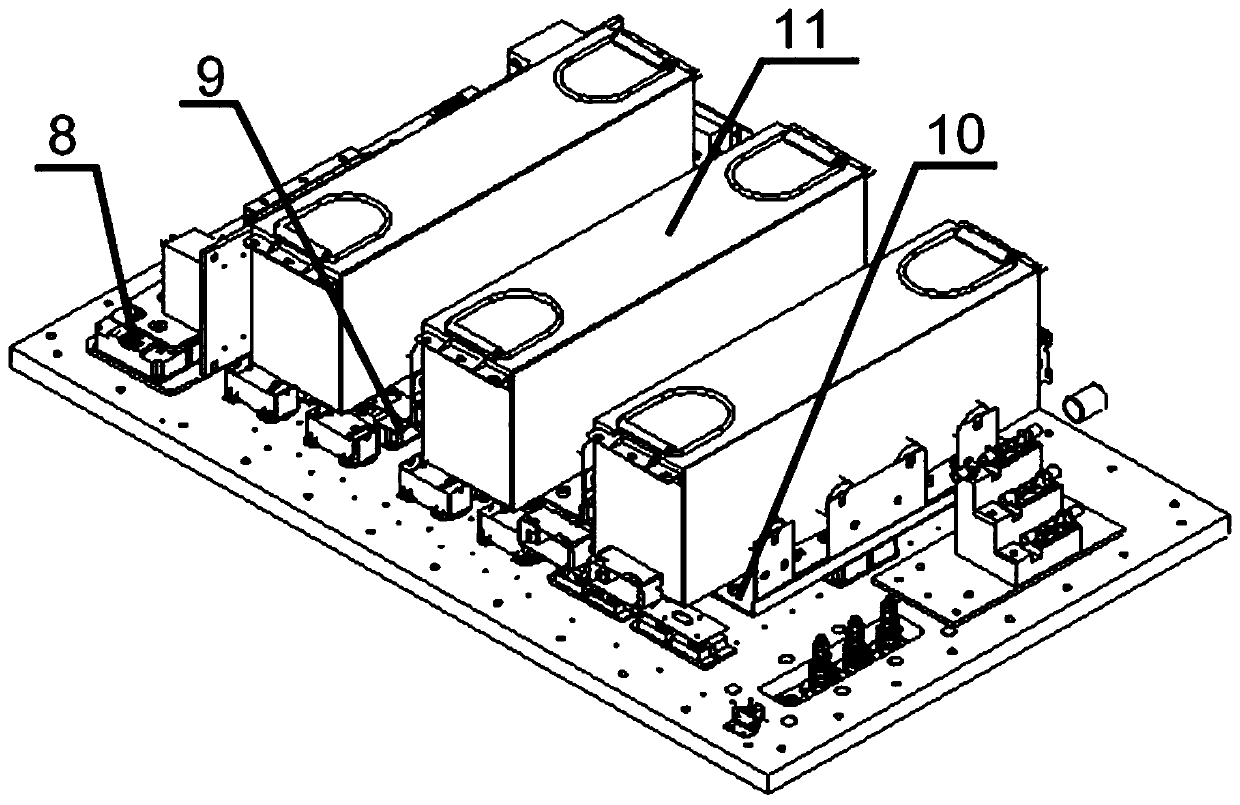

[0029] like figure 1 As shown, the integrated machine includes a permanent magnet synchronous motor 1 and a frequency converter 2. The frequency converter 2 is installed on the top of the permanent magnet synchronous motor 1, and the rear end of the permanent magnet synchronous motor 1 is provided with an input filter box 3. The permanent magnet synchronous motor 1 of the all-in-one machine adopts an encoderless design, which can also realize the precise control of the permanent magnet synchronous motor by the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com