Liquid light hydrocarbon bump formatting carburettor

A vaporizer and bubbling technology, applied in the direction of liquid fuel supply/distribution, combustion methods, etc., can solve the problems of high manufacturing cost and complex structure, and achieve the effect of reducing equipment manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

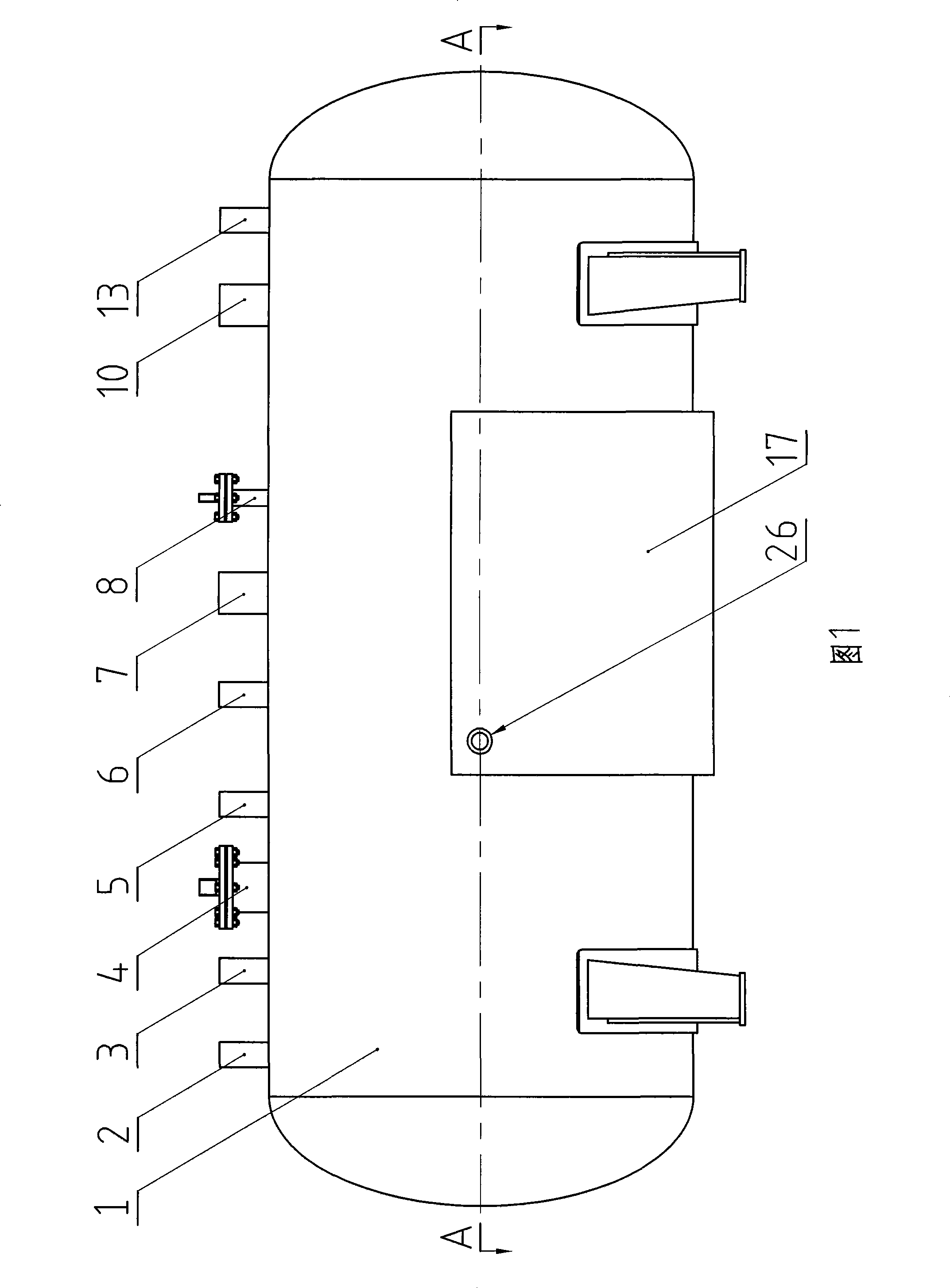

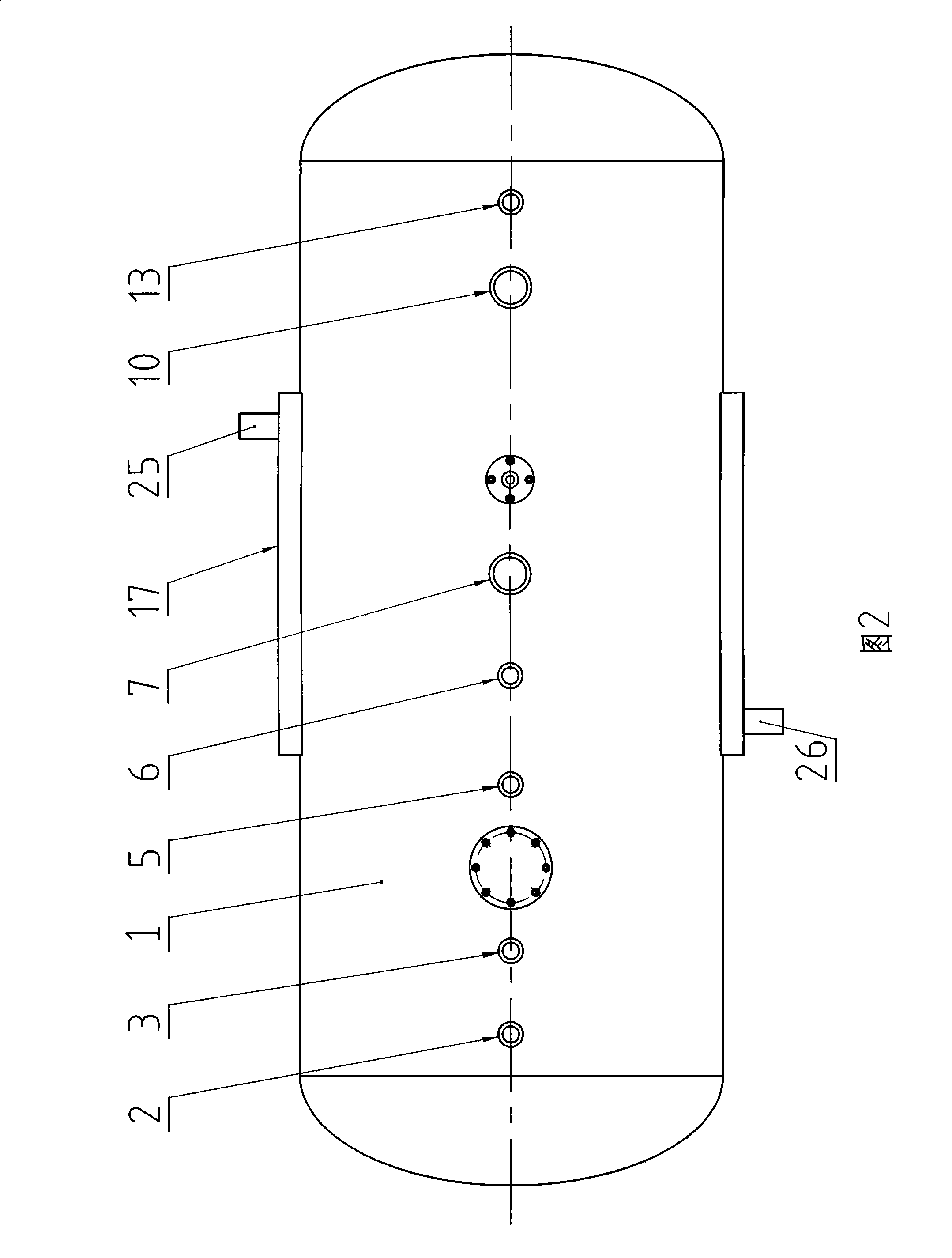

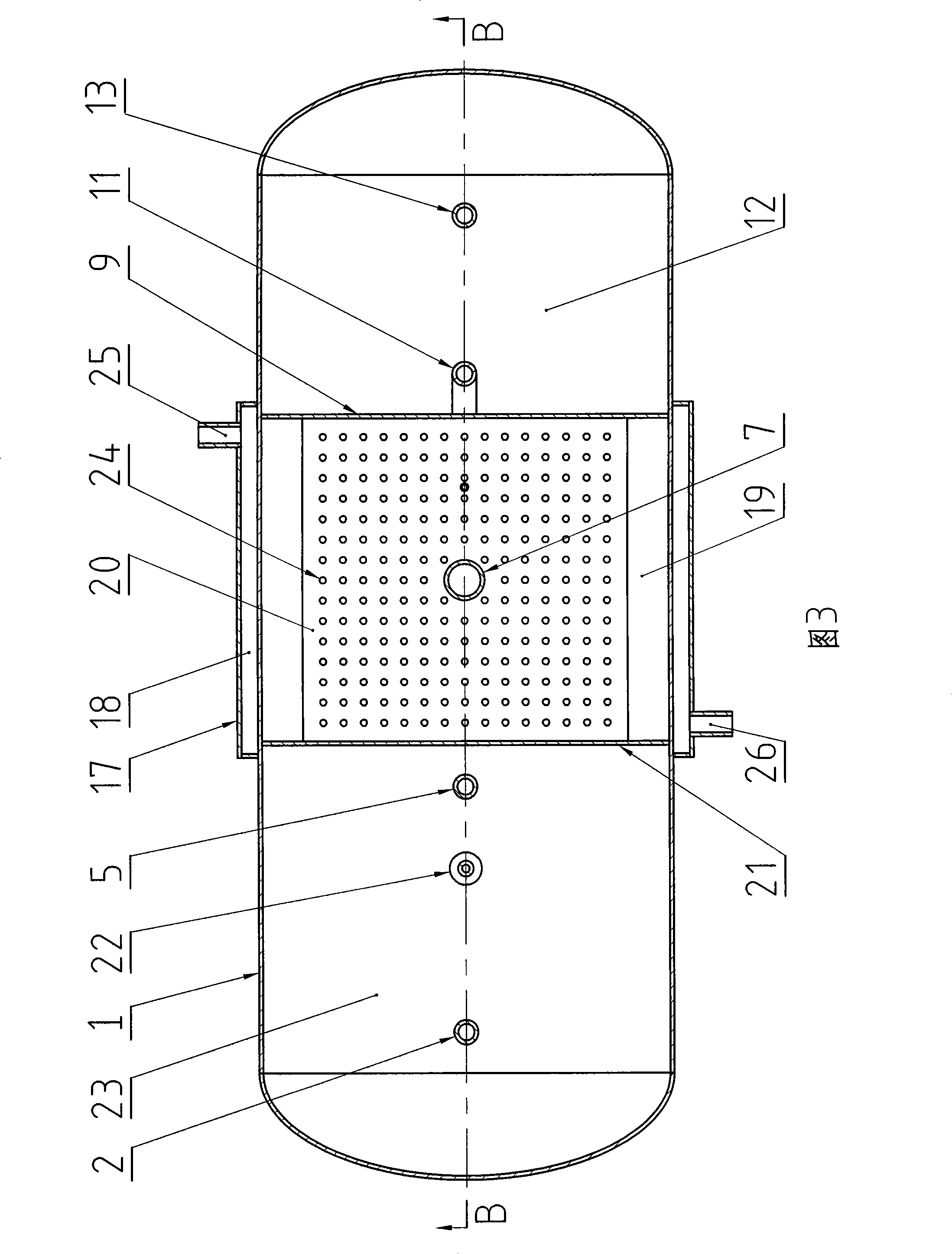

[0015]In Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5 and Fig. 6, the horizontal tank body 1 is welded by a cylindrical cylinder with a diameter of 2 meters rolled by steel plate, an oval head and a support The interior of the horizontal tank body 1 is divided into three cavities by a partition 21 and a partition 9 that are welded with two circular steel plates inside, which are respectively a raw material chamber 23, a vaporization chamber 19 and a residual liquid chamber 12, wherein The upper part of the circular partition 9 between the vaporization chamber 19 and the residual liquid chamber 12 is cut off to form a gap to connect the upper part of the vaporization chamber 19 and the residual liquid chamber 12; the oil inlet pipe 2 enters the raw material from the top of the raw material chamber 23 In the chamber 23, the distance between the end nozzle and the bottom of the raw material chamber 23 is 20 to 200 millimeters, and the function of the oil inlet pipe 2 is to transport the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com