Machining method and machining device for mechanical forming production of integral type moisture retaining cigarette case

A processing method and integrated technology, applied in the direction of packaging cigarettes, etc., can solve the problems of not providing, unable to apply integral moisturizing cigarette case, unable to produce integral moisturizing cigarette case, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

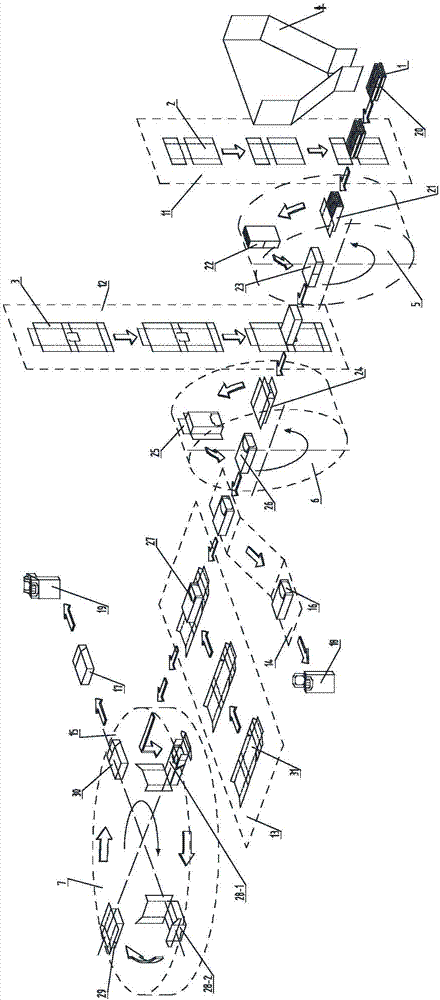

[0118] Step 1: At the cigarette group restraint station 20, place 20 cigarettes in a 7-6-7 arrangement along the longitudinal direction, and constrain them into a 7-6-7 cigarette group 1 for later use. Such as figure 1 , 12 shown.

[0119] Step 2, inner frame molding: according to the sequence, such as Figure 13 As shown, the paper inner frame 2 in the flat sheet state and the cigarette group 1 transported by the pick-and-place device 11 of the paper inner frame in the sheet state, and the glue spraying port 33 at the glue point 34 are sprayed with glue. Push it into the mold box 38 of the turret A, and then use the restraint of the mold box 38, the mechanical action of the equipment, and the rotation of the turret A to complete the paper at the pre-folding station 21 of the paper inner frame. The pre-folding action of the inner frame 2 is completed; the pre-folding action of the inner frame 2 is completed at the paper inner frame folding station 22; the inner frame 2 wrap...

Embodiment 2

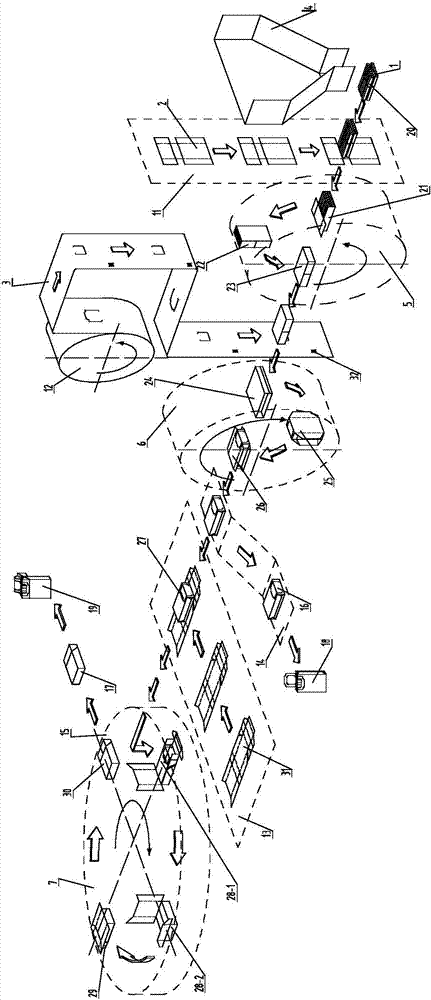

[0124] Step 1: At the cigarette group restraint station 20, place 20 cigarettes in a 7-6-7 arrangement along the longitudinal direction, and constrain them into a 7-6-7 cigarette group 1 for later use. Such as figure 2 , 12 shown.

[0125] Step 2, inner frame molding: according to the sequence, such as Figure 13 As shown, the paper inner frame 2 in the flat sheet state and the cigarette group 1 transported by the pick-and-place device 11 of the paper inner frame in the flat sheet state, and the glue spraying port 33 at the glue point 34 are sprayed with glue. Push it into the mold box 38 of the turret A, and then use the restraint of the mold box 38, the mechanical action of the equipment, and the rotation of the turret A to complete the paper at the pre-folding station 21 of the paper inner frame. The pre-folding action of the inner frame 2 is completed; the pre-folding action of the inner frame 2 is completed at the folding station 22 of the inner frame made of paper; t...

Embodiment 3

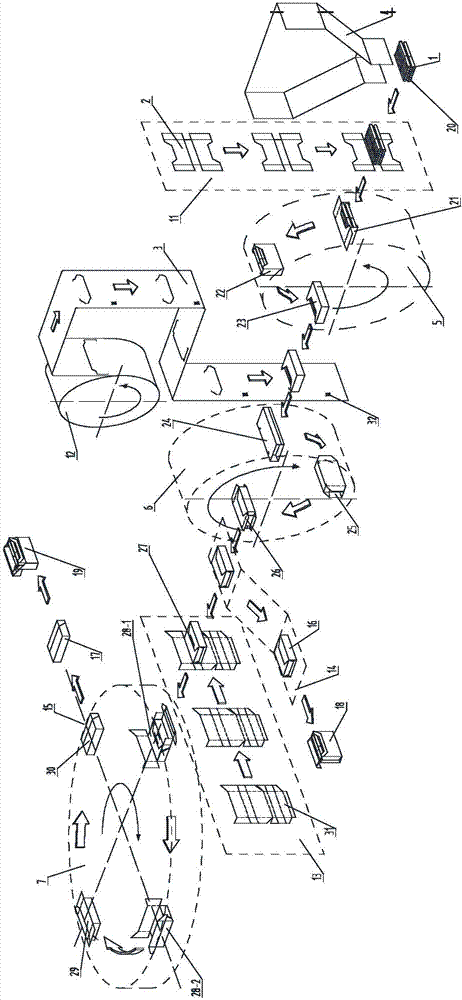

[0130] Step 1: At the cigarette group restraint station 20, place 20 cigarettes in a 7-6-7 arrangement along the horizontal direction, and constrain them into a 7-6-7 cigarette group 1 for later use. Such as image 3 shown.

[0131] Step 2, inner frame molding: according to the sequence, such as Figure 13 As shown, the paper inner frame 2 in the flat sheet state and the cigarette group 1 transported by the pick-and-place device 11 of the paper inner frame in the flat sheet state, and the glue spraying port 33 at the glue point 34 are sprayed with glue. Push it into the mold box 38 of the turret A, and then use the restraint of the mold box 38, the mechanical action of the equipment, and the rotation of the turret A to complete the paper at the pre-folding station 21 of the paper inner frame. The pre-folding action of the inner frame 2 is completed; the pre-folding action of the inner frame 2 is completed at the folding station 22 of the inner frame made of paper; the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com