Method for synthesizing cyanomethyl carboxylate

A technology for synthesizing cyanomethyl carboxylate and cyanomethyl carboxylate is applied in the preparation of carboxylic acid nitrile, chemical instruments and methods, preparation of organic compounds, etc., and can solve the problems of insufficient atom economy, large amount of catalyst, etc. , to achieve the effect of being conducive to large-scale industrial synthesis applications, single components, and reducing chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

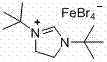

[0023] Embodiment one: containing 1,3-di-tert-butyl imidazolinium cation (molecular formula is [( t BuNCH 2 CH 2 N t Bu)CH][FeBr 4 ]) Synthesis of ionic iron complexes

[0024] Add 1,3-di-tert-butylimidazolinium chloride (0.22 g, 1.0 mmol) and NaBr (0.15 g, 1.5 mmol) sequentially to a solution of ferric tribromide (0.29 g, 1.0 mmol) in THF , reacted at 60°C for 24 hours, removed the solvent in vacuo, washed with hexane, drained, extracted with tetrahydrofuran, centrifuged to transfer the supernatant, added hexane to the supernatant for recrystallization, reddish-brown crystals were precipitated at room temperature, and the yield was 90% .

[0025] The chemical structural formula is as follows:

[0026]

[0027] Carry out elemental analysis to product, the result is as follows:

[0028] Elemental analysis

[0029]

C:(%)

H:(%)

N:(%)

theoretical value

23.64

4.15

5.01

actual value

23.88

4.31

5.34

[0030] This comp...

Embodiment 2

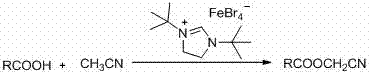

[0032] Embodiment two: [( t BuNCH 2 CH 2 N t Bu)CH][FeBr 4 ] Catalyzed esterification of benzoic acid with acetonitrile

[0033] Add benzoic acid (61.1 mg, 0.5 mmol), catalyst (28 mg, 0.05 mmol), di-tert-butyl peroxide (232 microliters, 1.25 mmol) and acetonitrile (10 milliliters) successively in the reaction flask. React at 110°C for 24 hours, cool to room temperature after the reaction, and purify the product by column chromatography (using a mixed solvent of ethyl acetate / petroleum ether with a volume ratio of 1:20 as the developing solvent), and the yield is 80%.

[0034] Add benzoic acid (61.1 mg, 0.5 mmol), catalyst (28 mg, 0.05 mmol), di-tert-butyl peroxide (186 microliters, 1 mmol) and acetonitrile (10 milliliters) to the reaction flask successively. React at 110°C for 24 hours, cool to room temperature after the reaction, and purify the product by column chromatography (using a mixed solvent of ethyl acetate / petroleum ether with a volume ratio of 1:20 as the deve...

Embodiment 3

[0036] Embodiment three: [( t BuNCH 2 CH 2 N t Bu)CH][FeBr 4 ] Catalyzed esterification of 4-methoxybenzoic acid with acetonitrile

[0037] Add 4-methoxybenzoic acid (76.1 mg, 0.5 mmol), catalyst (28 mg, 0.05 mmol), di-tert-butyl peroxide (232 μl, 1.25 mmol) and acetonitrile ( 10 ml), reacted at 100°C for 30 hours, cooled to room temperature after the reaction, and purified the product by column chromatography (using a mixed solvent of ethyl acetate / petroleum ether volume ratio of 1:5 as the developing solvent), the yield 85%.

[0038] Add 4-methoxybenzoic acid (76.1 mg, 0.5 mmol), catalyst (28 mg, 0.05 mmol), di-tert-butyl peroxide (278 μl, 1.5 mmol) and acetonitrile ( 10 ml), reacted at 100°C for 30 hours, cooled to room temperature after the reaction, and purified the product by column chromatography (using a mixed solvent of ethyl acetate / petroleum ether volume ratio of 1:5 as the developing solvent), the yield 84%.

[0039] Dissolve the product in CDCl 3 Medium (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com