Fulvic acid type three-dimensional network composite material, and preparation method and application thereof

A three-dimensional network and composite material technology, which is applied in the field of fulvic acid-type three-dimensional network composite materials and its preparation, can solve the problems of limited specific surface area, single function, low efficiency, etc., to improve soil structure, simple process, and reduce chemical pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

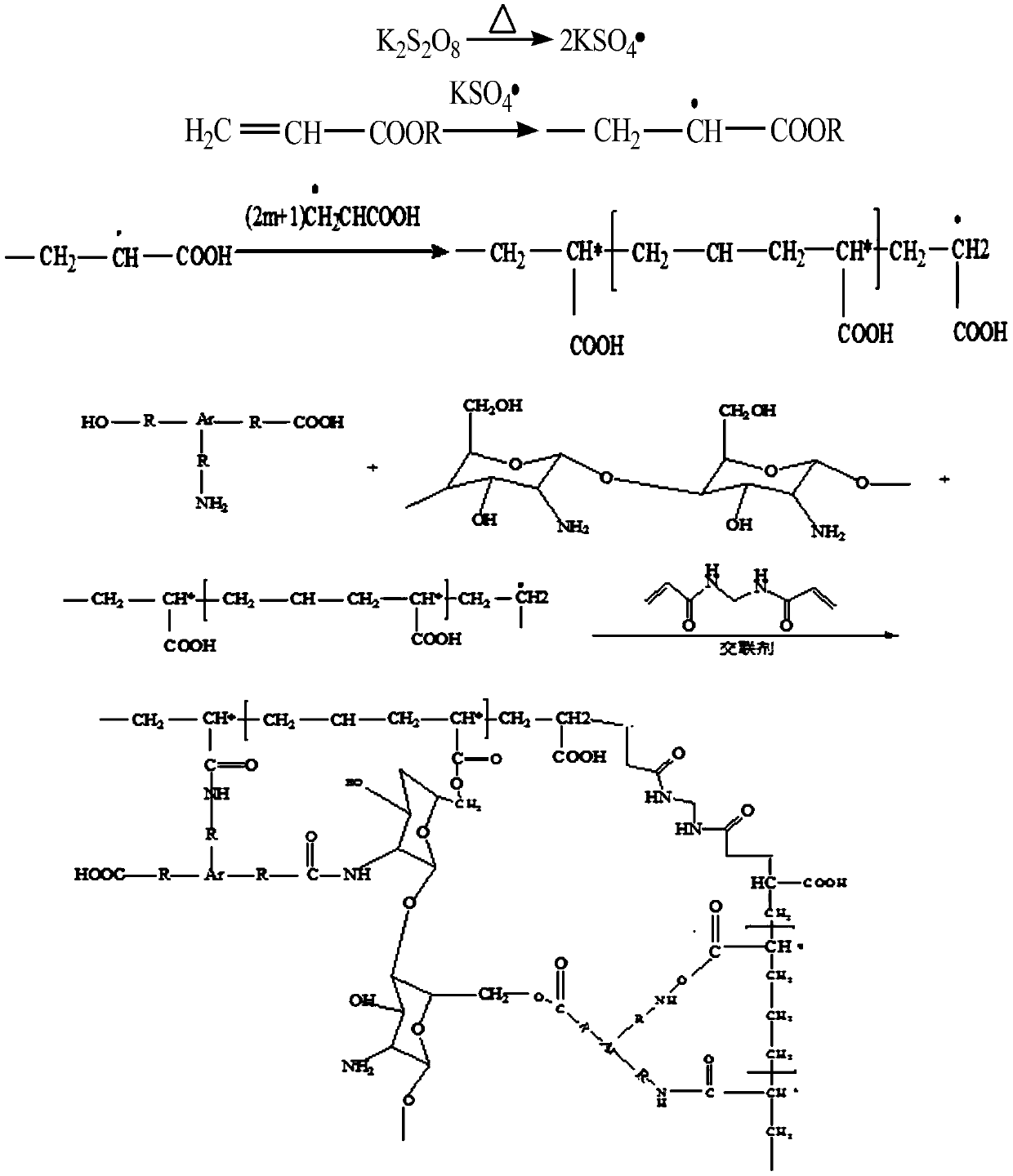

Method used

Image

Examples

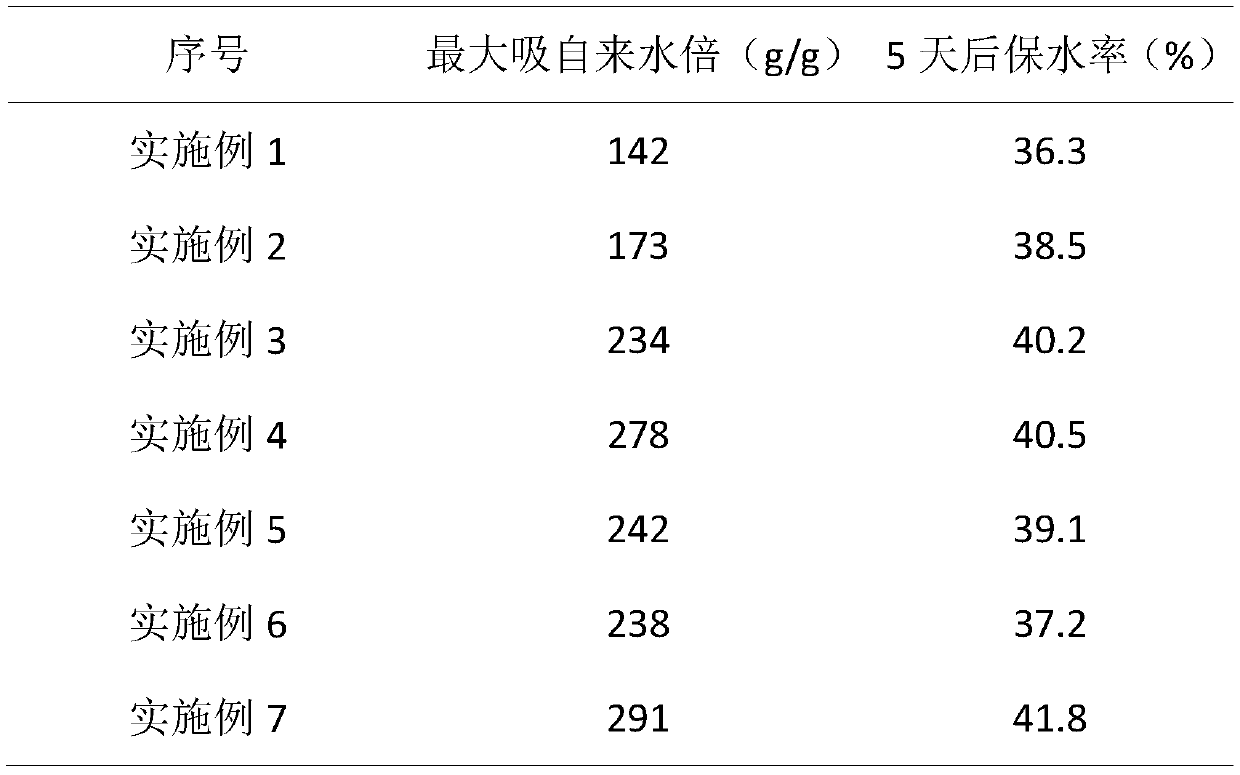

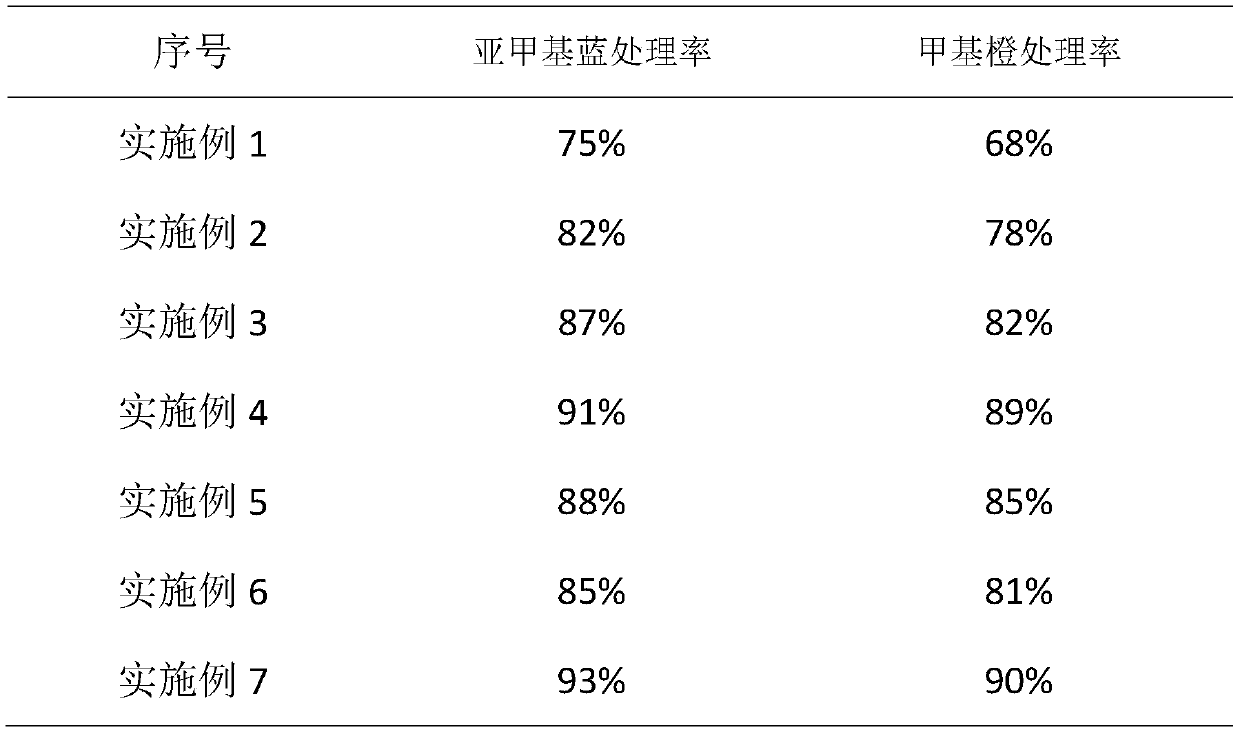

Embodiment 1

[0030] Weigh 1 part of fulvic acid and 0.3 part of chitosan into a three-necked flask, add 60 parts of distilled water, turn on the stirring device to stir at a rate of 120r / min, and at the same time raise the temperature from room temperature to 55 at a rate of 2°C / min. ℃; drop in 5.5 parts of acrylic acid with a neutralization degree of 20% and neutralize it with KOH in an ice-water bath at 0 °C, and control the dropping time for 30 minutes; then add 0.005 parts of potassium persulfate and 0.005 parts of N, N-Methylenebisacrylamide was dissolved in 15 parts of distilled water to make a solution, and the dropping time was controlled to be 35 minutes; then continue to heat up to 80°C at a heating rate of 2°C / min, and then stirred at a rate of 100r / min, when The reaction was stopped when the system was viscous and gelatinous and difficult to stir, and the product was taken out and dried at 80°C to obtain a fulvic acid-type three-dimensional network composite material.

Embodiment 2

[0032] Weigh 2 parts of fulvic acid and 0.5 part of cellulose into a three-neck flask, add 70 parts of distilled water, turn on the stirring device to stir at a rate of 160r / min, and at the same time raise the temperature from room temperature to 65°C at a rate of 4°C / min ; Add 7.5 parts of acrylic acid with a neutralization degree of 80% to 7.5 parts of acrylic acid, which was neutralized with NaOH under the condition of ice-water bath at 0°C in advance, and control the dropping time for 40 minutes; then add 0.09 parts of ammonium persulfate and 0.02 parts of N-formaldehyde Diethanolamine was dissolved in 15 parts of distilled water to make a solution, and the dropping time was controlled to be 45 minutes; then continue to heat up to 75°C at a heating rate of 4°C / min, and then stirred at a rate of 120r / min, when the reaction system became viscous Stop the reaction when the gel is difficult to stir, take out the product and dry it at 80°C to obtain the fulvic acid type three-di...

Embodiment 3

[0034] Weigh 3 parts of fulvic acid and 0.5 part of cellulose into a three-necked flask, add 80 parts of distilled water, turn on the stirring device to stir at a rate of 140r / min, and at the same time raise the temperature from room temperature to 60°C at a rate of 3°C / min ; Drop in 75g of acrylic acid with a neutralization degree of 60% and neutralize it with KOH at 0°C in an ice-water bath, and control the dropping time for 40 minutes; then add 0.09 parts of potassium persulfate and 0.03 parts of N-methyl Diethanolamine was dissolved in 15 parts of distilled water to make a solution, and the dripping time was controlled to be 40 minutes; then continue to heat up to 80°C at a heating rate of 3°C / min, and then stirred at a rate of 110r / min, when the reaction system became viscous and coagulated Stop the reaction when the jelly-like stirring is difficult, take out the product and dry it at 80°C to obtain the fulvic acid type three-dimensional network composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com