Preparation method of microsphere accumulation type polystyrene porous material

A technology of polystyrene and porous polystyrene, which is applied in the field of preparation of microsphere-packed polystyrene porous materials, can solve the problems of high manufacturing cost of CMPs and PIMs, poor chemical stability of COFs, and low regularity of micropore network , to achieve the effect of easy industrial mass production and application, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

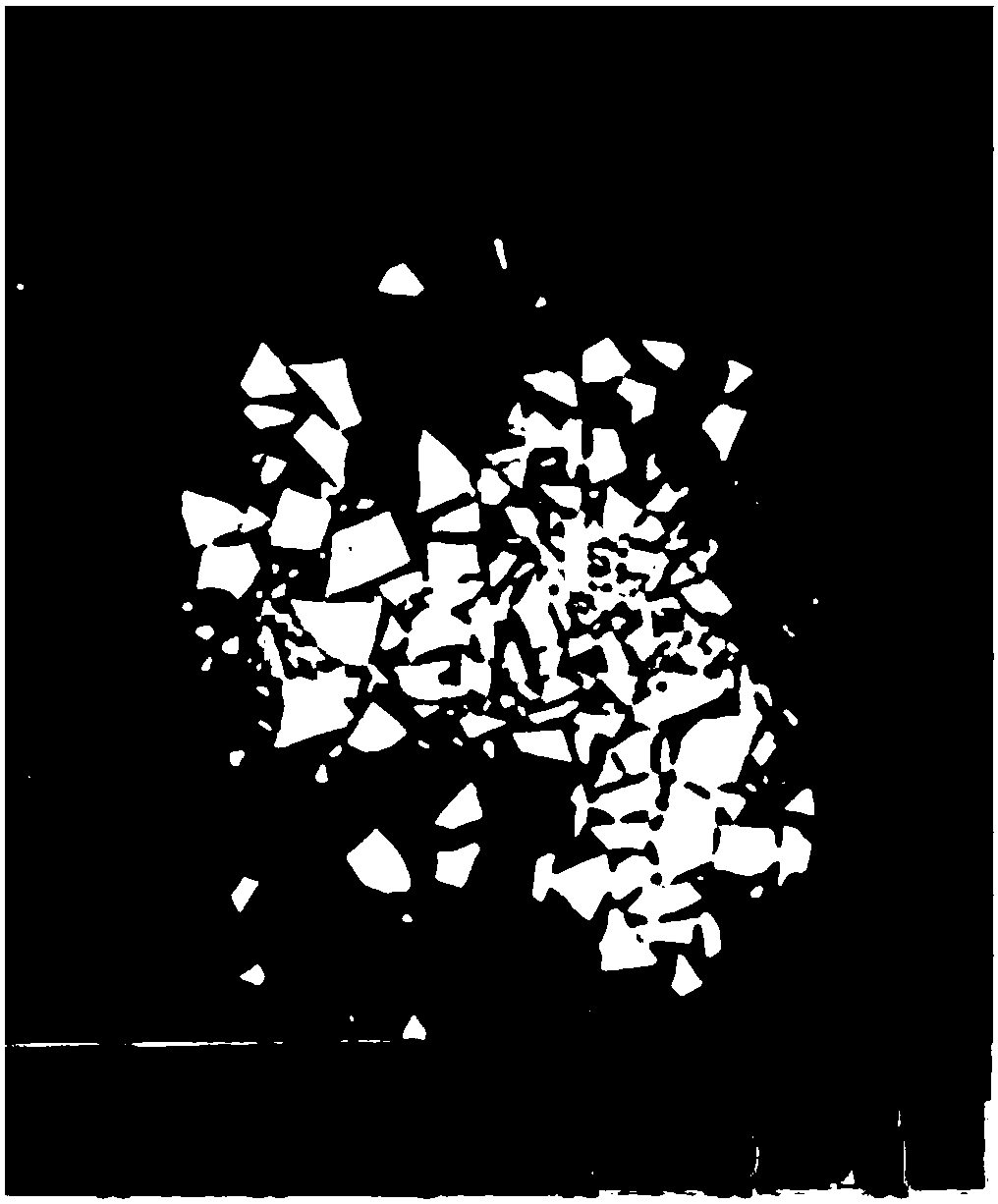

Image

Examples

example 1

[0033] 1. Preparation of Polystyrene Microspheres

[0034] Weigh 10 g of styrene monomer; 2.587 g of dimethyl diallyl ammonium chloride (DMDAAC); 0.173 g of azobisisobutyronitrile (AIBN); 0.5 g of polyvinylpyrrolidone (PVP); divinylbenzene (DVB ) is 0.125 g of crosslinking agent; 140 ml of absolute ethanol and 5.4 ml of deionized water are configured as solvents, and kept at 75° C. for 24 hours to prepare polystyrene microspheres.

[0035] 2. Preparation of polystyrene materials by microsphere packing method

[0036] Mix polystyrene microspheres with an appropriate amount of polyacrylic acid (microsphere mass:acrylic acid mass=1:0.01) in deionized water, and pour the mixture into a flat and clean container for accumulation. After the microspheres settle, the solvent evaporates naturally. polystyrene material.

[0037] 3. Preparation of polystyrene porous material

[0038] Add polystyrene film, anhydrous ferric chloride, and dimethoxymethane (FDA) to 1.2-dichloroethane (1g s...

example 2

[0040] 1. Preparation of Polystyrene Microspheres

[0041] Weigh 10 g of styrene monomer; 2.587 g of dimethyl diallyl ammonium chloride (DMDAAC); 0.7 g of dibenzoyl peroxide; 0.5 g of polyvinylpyrrolidone (PVP); 0.125 g of the joint agent; 140 ml of absolute ethanol and 5.4 ml of deionized water were configured as solvents, and kept at 75° C. for 24 hours to prepare Poly(St-DMDAAC) microspheres.

[0042] 2. Preparation of polystyrene materials by microsphere packing method

[0043] Mix polystyrene microspheres with an appropriate amount of polyacrylic acid (5% of the mass of the microspheres) in ethanol-water (alcohol-water ratio is 1:9) solvent, pour the mixture into a flat and clean container for accumulation, and wait until microspheres The ball settles, the solvent evaporates naturally, and polystyrene material is obtained.

[0044] 3. Preparation of polystyrene porous material

[0045] Add polystyrene film, anhydrous ferric chloride, and dimethoxymethane (FDA) to 1.2-d...

example 3

[0047] 1. Preparation of Polystyrene Microspheres

[0048] Weigh 10 g of styrene monomer; 2.587 g of dimethyl diallyl ammonium chloride (DMDAAC); 0.5 g of potassium persulfate; 0.5 g of polyvinylpyrrolidone (PVP); 0.125 g of divinylbenzene (DVB) as crosslinking agent g: 140ml of absolute ethanol and 5.4ml of deionized water were configured as solvents, and kept at 75°C for 24h to prepare polystyrene microspheres.

[0049] 2. Preparation of polystyrene materials by microsphere packing method

[0050] Mix the prepared Poly(St-DMDAAC) microspheres with an appropriate amount of polyacrylic acid (10% of the mass of the microspheres) in ethanol-water (alcohol-water ratio is 4; 6) solvent, and pour the mixture into a flat and clean Stack in the container, wait for the microspheres to settle, and the solvent evaporates naturally to obtain polystyrene material.

[0051] 3. Preparation of polystyrene porous material.

[0052] Add polystyrene film, anhydrous ferric chloride, and dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com