System and process for comprehensive utilization of oil shale destructive distillation and semicoke gasification

A technology of oil shale and dry distillation, applied in the petroleum industry, special form of dry distillation, preparation of liquid hydrocarbon mixture, etc., can solve the difficulty in transporting semi-coke and shale ash, no public reports of patented technology, shale oil yield Reduce and other problems, to avoid loss and environmental pollution, reduce thermal pollution and chemical pollution, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

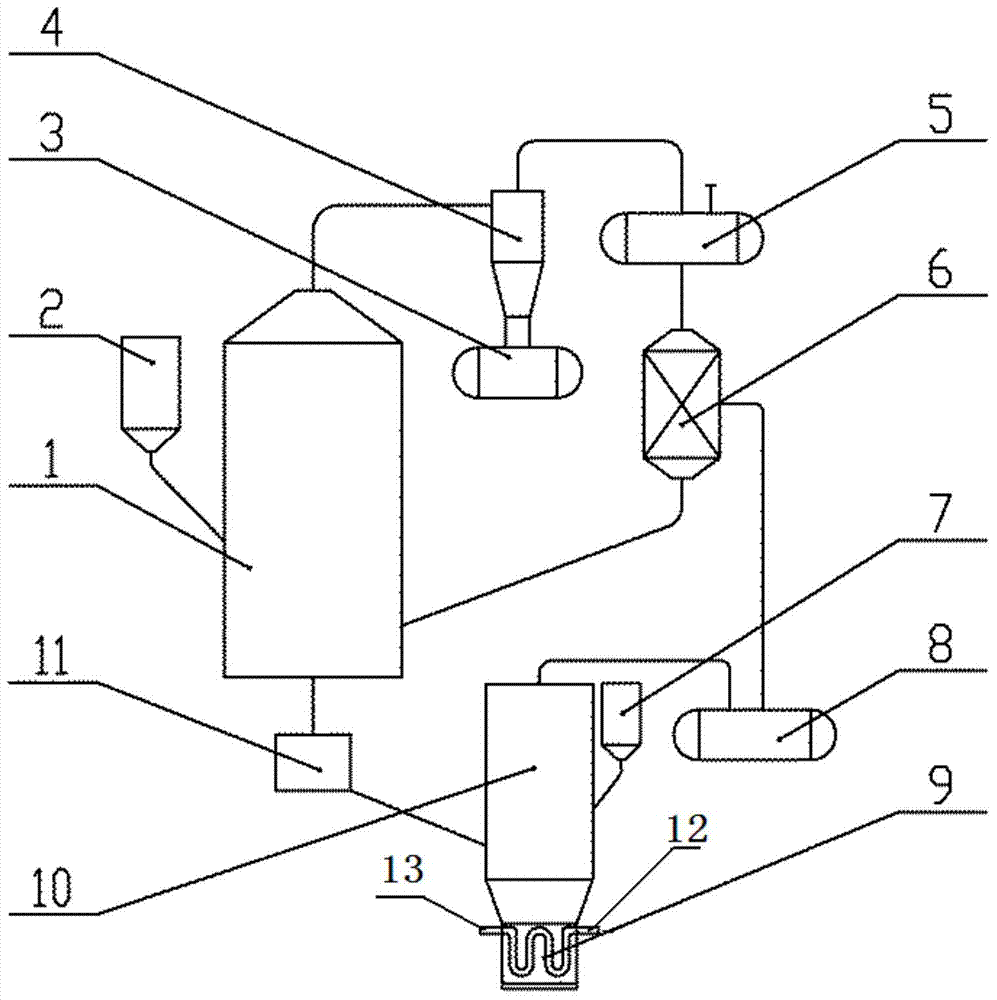

[0025] A system for comprehensive utilization of oil shale dry distillation and semi-coke gasification, including dry distillation furnace 1, oil shale silo 2, oil storage tank 3, oil-gas separator 4, gas storage tank 5, gas heater 6, gas Combustion fuel bin 7, combustible gas tank 8, gasifier 10 and conveying device 11; among them, dry distillation furnace 1 is used for dry distillation of the oil shale sent through oil shale bunker 2, and is connected to oil-gas separator 4, oil and gas The separator 4 is connected to the gas storage tank 5 and the oil storage tank 3; the gasification furnace 10 is connected to the lower port of the carbonization furnace 1 through a conveying device 11, and is used to make the dry distillation product semi-coke of the carbonization furnace 1 and the gasified fuel bin 7 The oil shale sent in undergoes a gasification reaction, and the gasifier 10 is also connected with the combustible gas tank 8; the gas heater 6 is connected with the dry disti...

Embodiment 2

[0027] A system for comprehensive utilization of oil shale dry distillation and semi-coke gasification, such as figure 1 Shown: including carbonization furnace 1, oil shale silo 2, oil storage tank 3, oil-gas separator 4, gas storage tank 5, gas heater 6, gasification fuel bin 7, combustible gas tank 8, heat exchanger 9 , a gasification furnace 10 and a conveying device 11; wherein, the dry distillation furnace 1 is used for dry distillation of the oil shale sent through the oil shale bunker 2, and is connected to the oil-gas separator 4, and the oil-gas separator 4 is connected with the gas storage tank 5 and The oil storage tank 3 is connected; the gasification furnace 10 is connected to the lower port of the carbonization furnace 1 through the conveying device 11, and is used to gasify the carbonization product semi-coke of the carbonization furnace 1 and the oil shale sent through the gasification fuel bin 7 reaction, the gasifier 10 is also connected with the combustible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com