Novel efficient flue gas desulfurization agent and method for treating desulfurization agent

A desulfurizer, a new type of technology, applied in the direction of separation methods, chemical instruments and methods, fuels, etc., can solve the problems of inefficient utilization, difficulty in popularization, and inability to treat waste liquid, so as to reduce emissions and alleviate the pressure of air pollution prevention and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

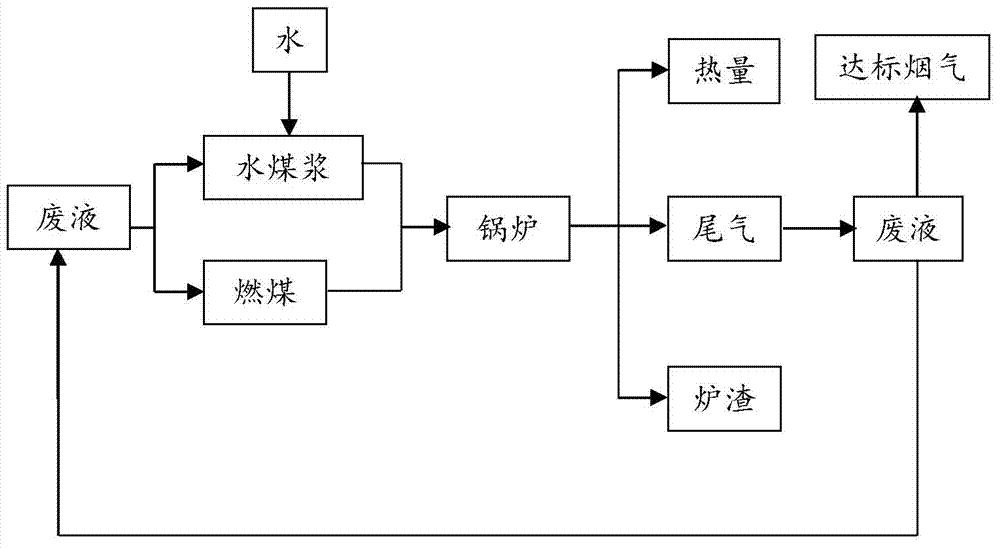

[0019] A new type of high-efficiency flue gas desulfurizer and a method for treating the desulfurizer, including the preparation of the desulfurizer and the absorption of SO 2 The desulfurizer is mixed with coal powder to prepare two parts of coal water slurry.

[0020] (1) Add CaO to the black liquor obtained by straw subtraction hydrogen peroxide pulping to prepare a desulfurizer, the concentration of which is subject to the uniform spraying of the nozzle of the desulfurization tower. The desulfurization agent is transported to the top of the desulfurization tower, pressurized and sprayed into mist, and the flue gas after dust removal enters from the bottom of the desulfurization tower along with the fan, and after being absorbed and desulfurized by the desulfurizer, it is condensed and dehumidified to be discharged.

[0021] (2) Absorbed SO 2 The desulfurizer is mixed with coal powder to make coal water slurry, which is transported to the furnace and fully utilized as fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com