System and process for producing oil by hydrotorting oil shale under increased pressure

A technology of hydrogenation carbonization and oil shale, which is applied in the petroleum industry, special carbonization, coking ovens, etc., can solve the problems of technical public reporting, etc., and achieve the effects of reducing environmental pollution, improving quality and yield, and increasing additional benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

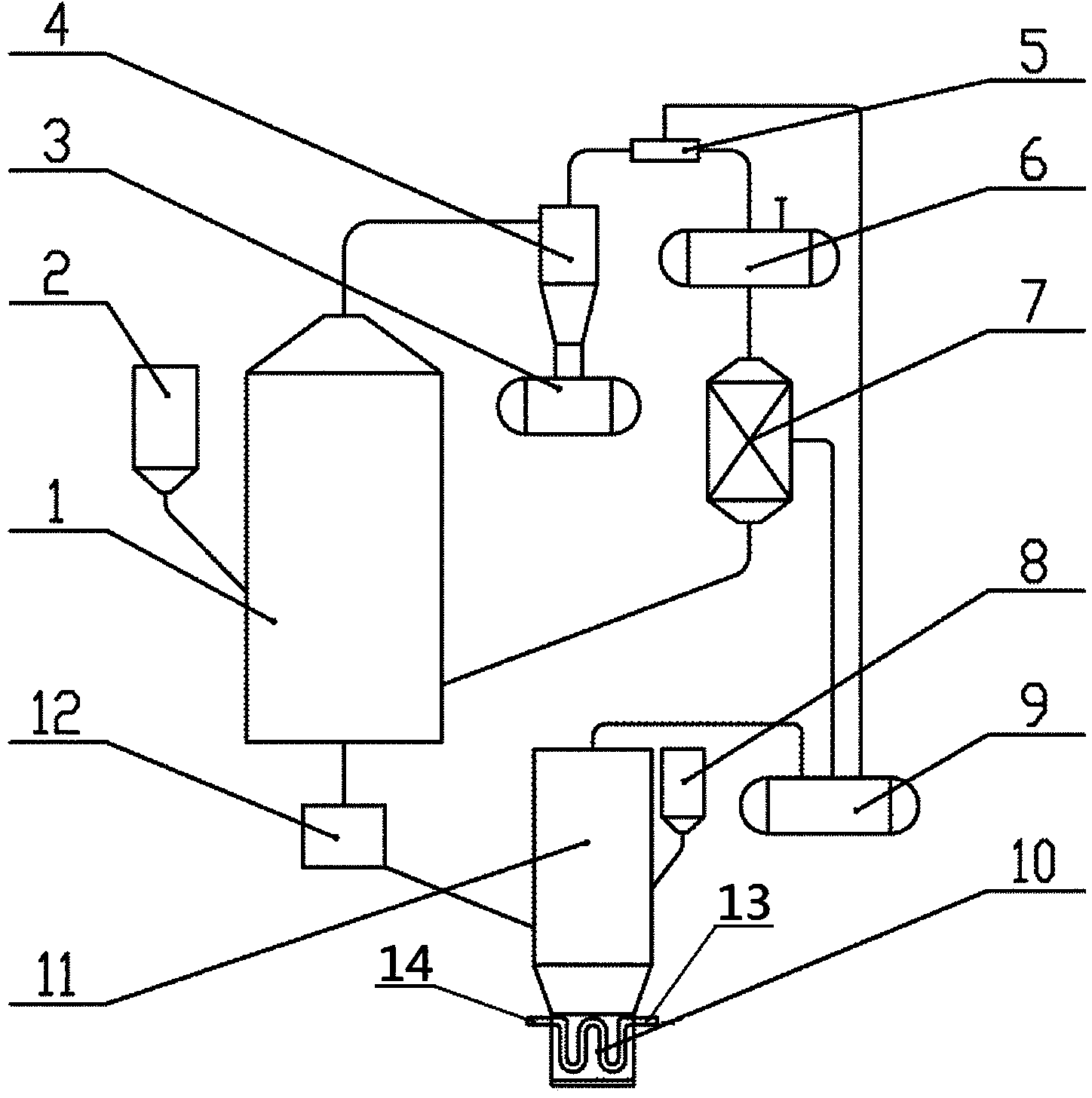

[0032] An oil shale pressurized hydrogenation carbonization oil production system, comprising a carbonization furnace 1, an oil shale silo 2, an oil storage tank 3, an oil-gas separator 4, a hydrogen separator 5, a hydrogen-rich gas tank 6, and a gas heater 7. Gasification fuel bin 8, combustible gas tank 9, gasification furnace 11, and conveying device 12, wherein: carbonization furnace 1 is used for carbonization of oil shale fed through oil shale silo 2, and carbonization furnace 1 is connected to the oil and gas Separator 4, oil-gas separator 4 is connected with hydrogen separator 5 and oil storage tank 3; Hydrogen gas, the hydrogen-rich gas tank 6 is connected to the gas heater 7; the gasification furnace 11 is connected to the lower port of the carbonization furnace 1 through the conveying device 12, and is used to transfer the semi-coke of the carbonization product of the carbonization furnace 1 to the gasification fuel bin 8 The gasification reaction of the imported oi...

Embodiment 2

[0034] An oil shale pressurized hydrogenation dry distillation oil production system, such as figure 1 As shown, it includes dry distillation furnace 1, oil shale silo 2, oil storage tank 3, oil gas separator 4, hydrogen gas separator 5, hydrogen-rich gas tank 6, gas heater 7, gasification fuel tank 8, combustible gas tank 9. Heat exchanger 10, gasifier 11, and conveying device 12, wherein: dry distillation furnace 1 is used for dry distillation of oil shale fed through oil shale silo 2, and dry distillation furnace 1 is connected to oil-gas separator 4 for oil-gas separation The device 4 is connected with the hydrogen separator 5 and the oil storage tank 3; the hydrogen separator 5 is connected with the hydrogen-rich gas tank 6, and the hydrogen separator 5 is used to separate the gas produced by the dry distillation of oil shale to obtain hydrogen-rich gas, hydrogen-rich gas The tank 6 is connected to the gas heater 7; the gasification furnace 11 is connected to the lower po...

Embodiment 3

[0036] An oil shale pressurized hydrogenation dry distillation oil production process, the process uses the oil shale pressurized hydrogenation dry distillation oil production system described in embodiment 2, comprising the following steps:

[0037] a. crush and dry the oil shale to obtain granular oil shale with a particle size greater than 4mm and powdery oil shale with a particle size not greater than 4mm, store the granular oil shale in the oil shale silo 2, and put the powdery oil Shale is stored in the gasification fuel bunker 8;

[0038] b. The granular oil shale in step a descends into the carbonization furnace 1, and conducts carbonization under the environment of 450-550°C and 2-3MPa to produce semi-coke, shale oil and gas; the gas and shale oil pass through the oil-gas separator 4 After separation, the shale oil is stored in the oil storage tank 3, the gas enters the hydrogen separator 5 and is separated into hydrogen-rich gas and dehydrogenated gas, the hydrogen-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com