Coke breeze-containing mixed fuel for blast furnace coal injection and preparation method thereof

A technology of mixed fuel and blast furnace coal injection, which is applied in the fields of blast furnace pulverized coal injection and blast furnace ironmaking, can solve the problem of high cost of mixed fuel for blast furnace coal injection, improve the comprehensive utilization of resources, reduce costs, and reduce solid waste generation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

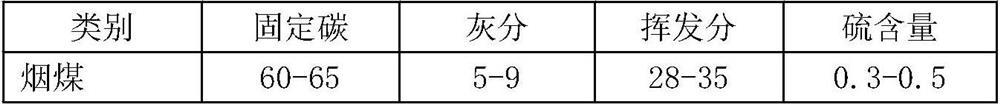

[0035] Example 1, the calorific value of bituminous coal in the mixed fuel is 27957.85kJ / kg, and the combustion rate is 76.77%; the calorific value of anthracite is 30709.39J / kg, and the combustion rate is 59.72%; The combustion rate is 64.61%; the calorific value of the coke powder prefabricated powder is 34601.02kJ / kg, and the combustion rate is 45.23%; the ingredients of the raw materials in Example 1 are shown in Table 4.

[0036] Table 4 The raw material components of Example 1 of the present invention, unit: weight percent.

[0037] category fixed carbon Ash Volatile matter Sulfur content bituminous coal 62.64 5.72 31.64 0.42 anthracite 79.42 10.88 9.7 0.48 semi charcoal 74.72 11.78 13.5 0.32 charcoal prefabricated powder 87.62 11.3 1.08 0.66

[0038] Mixed fuel for 3200m 3 When the blast furnace is blown, the process control parameters are: hot air temperature 1150°C, oxygen enrichment rate 1%, blast humidity 1%,...

Embodiment 2

[0039] Embodiment 2, the calorific value and combustion rate of bituminous coal in the mixed fuel, the calorific value and combustion rate of anthracite; the calorific value and combustion rate of semi-coke and the calorific value and combustion rate of coke powder prefabricated powder are the same as embodiment 1; embodiment 2 Each raw material composition is with embodiment 1.

[0040] Mixed fuel for 3200m 3 When the blast furnace is injected, the process control parameters are the same as in Example 1; the indicators for smelting one ton of molten iron produced by the blast furnace are as follows: coal ratio: 146kg / t; coke ratio: 385kg / t; fuel ratio: 531kg / t; hot air temperature: 1150°C ; Theoretical combustion temperature: 2226°C; Heat loss: 6.069%; Bosh gas: 1462.32m 3 / t; direct reduction degree: 0.51; gas utilization rate: 0.454; slag basicity: 1.14; injection cost: 132.7 yuan / t.

Embodiment 3

[0041] Embodiment 3, the calorific value and combustion rate of bituminous coal in the mixed fuel, the calorific value and combustion rate of anthracite; the calorific value and combustion rate of semi-coke and the calorific value and combustion rate of coke powder prefabricated powder are the same as embodiment 1; embodiment 3 Each raw material composition is with embodiment 1.

[0042] Mixed fuel for 3200m 3 When the blast furnace is injected, the process control parameters are the same as in Example 1; the indicators for blast furnace production and smelting one ton of molten iron are as follows: coal ratio: 148kg / t; coke ratio: 385kg / t; fuel ratio: 533kg / t; hot air temperature: 1150°C; Theoretical combustion temperature: 2220°C; Heat loss: 6.046% Bosh gas: 1467.85m 3 / t; direct reduction degree: 0.51; gas utilization rate: 0.451; slag basicity: 1.15; injection cost: 117.38 yuan / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com