Hill wind power plant maintenance task intelligent scheduling method

A technology for intelligent scheduling and wind farms, which is applied in the direction of instruments, data processing applications, and information technology support systems, etc., can solve the problems of low resource utilization and low maintenance efficiency in maintenance and inspection tasks, so as to improve the comprehensive utilization of resources and reduce Equipment failure rate, the effect of enriching the theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

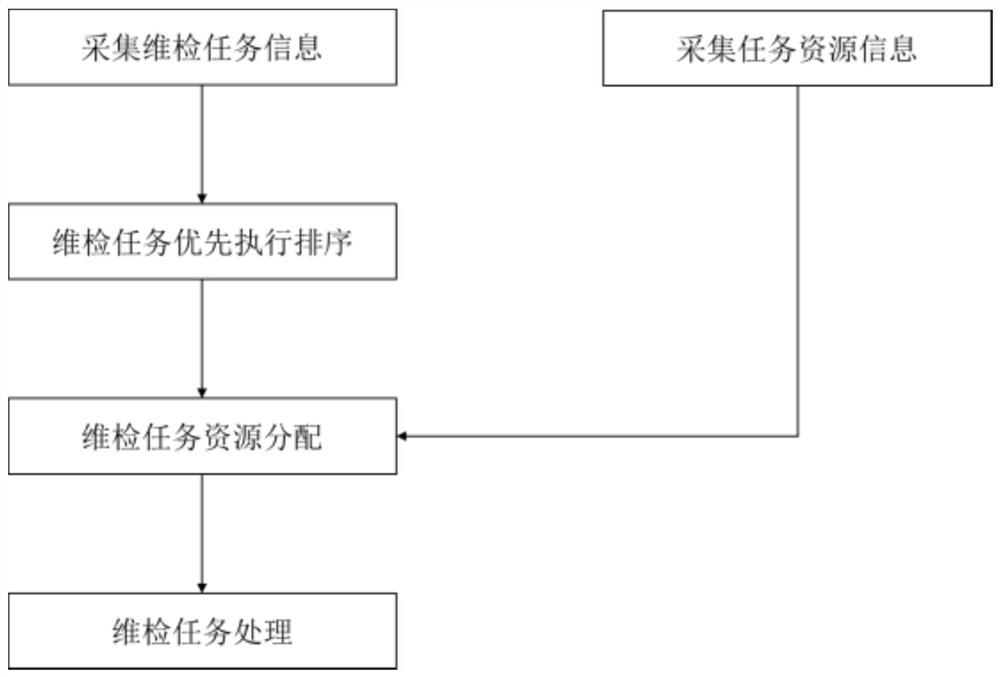

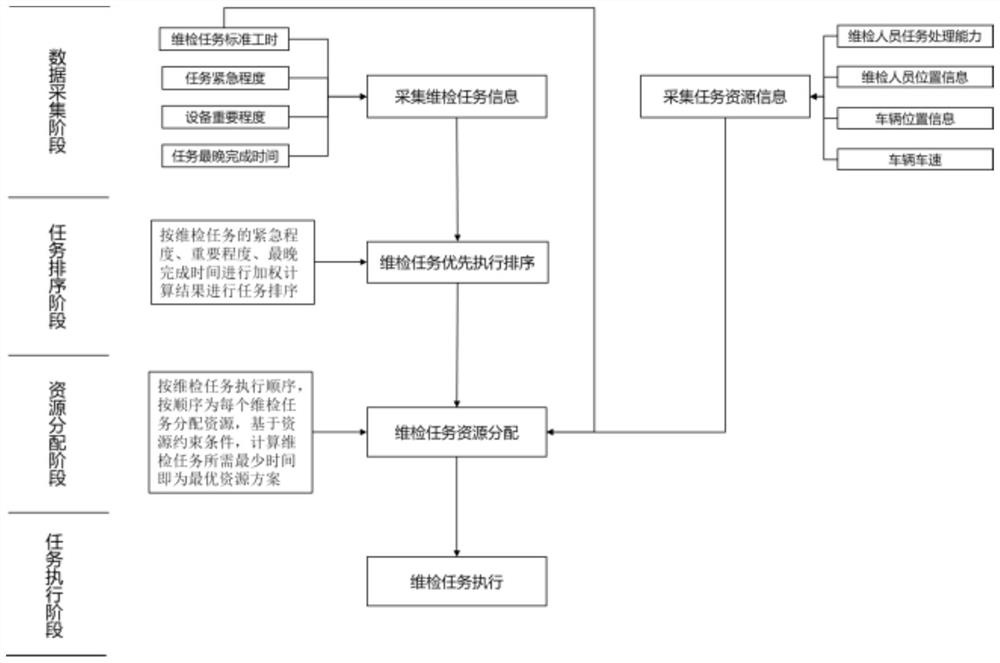

[0025] S1. Collect maintenance task information and status, set different information collection rules for different types of maintenance tasks, and extract task-related data information; figure 1 The task scheduling flow chart shown.

[0026] S2. Collect task resource information. Maintenance resources include maintenance personnel and vehicles, and information related to the above resources needs to be collected;

[0027] S3. Sorting the execution priority of the maintenance and inspection tasks, according to the comprehensive calculation of the urgency of the tasks, the importance of the maintenance and inspection equipment, and the latest completion time of the maintenance and inspection, and sorting the execution priorities of the maintenance and inspection tasks;

[0028] S4. The maintenance task resource allocation plan, the shortest time of the sum of the maintenance task waiting time and the maintenance task processing time is the optimal allocation plan of the mainte...

Embodiment 2

[0032] The difference technology with embodiment one is as follows:

[0033] S1.1: Maintenance tasks are divided into planned maintenance tasks and temporary maintenance tasks. The planned maintenance tasks are updated at 24 o'clock every day, and are included in the maintenance task pool for task sorting and allocation. The system collects relevant equipment information for temporary maintenance tasks, updates the temporary maintenance information every 2 hours, and counts it into the maintenance task pool for task sorting and allocation.

[0034] S1.2: Collect maintenance task information, including fault type, task urgency, equipment location information, equipment importance, task completion time, and task processing standard working hours.

[0035] S1.2.1: Fault type information includes fault cause and task fault handling standard. By clarifying the cause of the fault and the fault handling standard, it is possible to accurately estimate the fault handling time and ass...

Embodiment 3

[0043] The difference technology with embodiment two is:

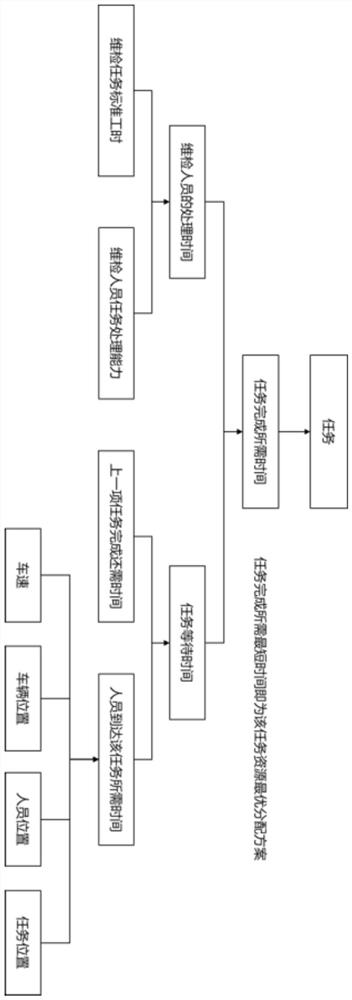

[0044] S2.1: Set the maintenance personnel as Rn, (n is 1, 2, 3..., n≥1). Maintenance personnel information includes task processing capabilities and personnel location information.

[0045] S2.1.1 The task processing ability of maintenance personnel represents their proficiency in handling tasks. Different maintenance personnel have different proficiency in handling the same task, and the same maintenance personnel have inconsistent proficiency in processing different tasks. Let the task processing ability be D, and D is 0. The value between -1, the more proficient the task, the larger the value, the less familiar the task processing, the smaller the value, and 0 if you do not have the processing ability of a certain task. The length of time for the maintenance personnel to process tasks = the standard man-hours for processing a certain task / the processing capacity of a maintenance personnel for a certain task. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com