Method for preparing grape distilled liquor through solid-liquid cross steaming and product thereof

A technology for distilled wine and dry red wine, which is applied in the field of grape distilled wine by solid-liquid series steaming. It can solve the problems of unguaranteed quality of added fruit juice, affecting the aroma of distilled wine, and affecting the senses of grape distilled wine, so as to enrich the aroma and fragrance of the product. Enrich and complex, improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

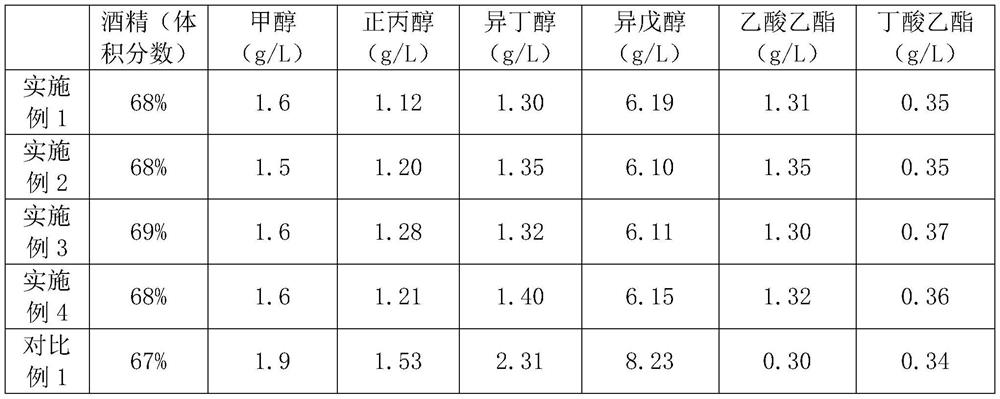

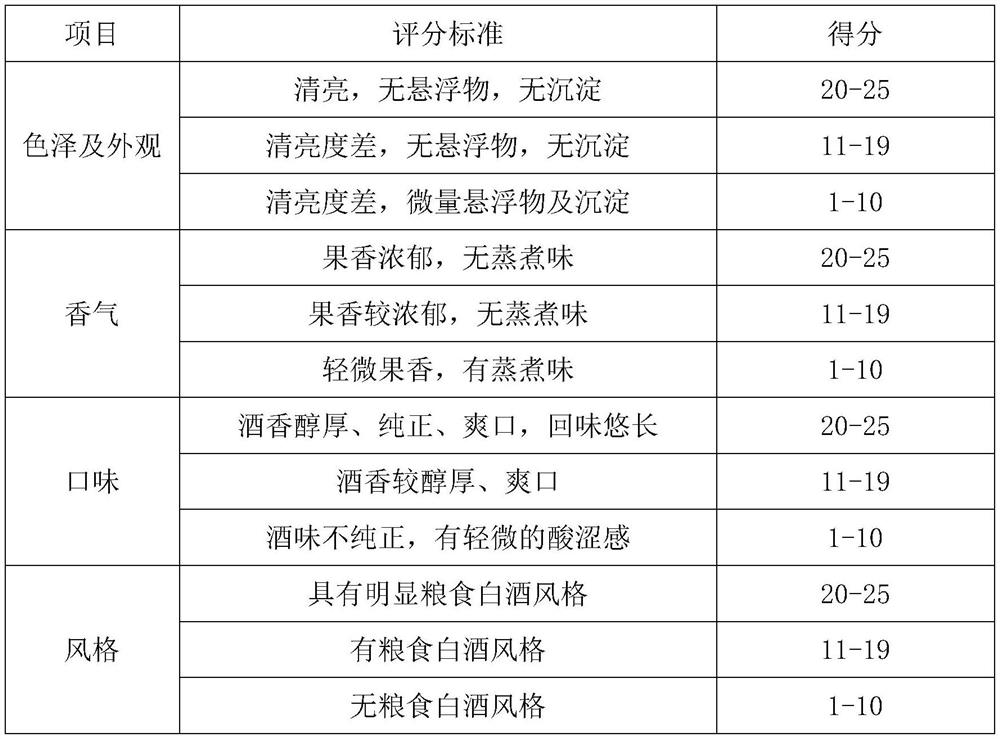

Embodiment 1

[0043] A method for preparing grape distilled wine by mixing solid-liquid steam, the steps are as follows:

[0044] (1) Preparation of distillation raw materials: collect the grape skin residue after fermentation of fresh dry red wine (Cabernet Sauvignon), and dry red wine (Cabernet Sauvignon) aged for 5 years (the aging container is a stainless steel tank and the temperature is 18°C). ) by 1:2 volume ratio batching, obtain distillation raw material for subsequent use;

[0045] (2) Install sieve plate: add a copper sieve plate with an aperture of 0.2cm at the upper 3 / 5 of the Charente pot;

[0046] (3) Feeding: pour the dry red wine that needs to be distilled into the still pot, the volume is 60% of the still pot volume, place the grape skin residue on the sieve plate, and spread evenly;

[0047] (4) String distillation: the above-mentioned distillation raw materials are distilled. Do not cut off the head of the wine, the temperature in the kettle is controlled at 80 ° C, an...

Embodiment 2

[0051] A method for preparing grape distilled wine by mixing solid-liquid steam, the steps are as follows:

[0052] (1) Preparation of distillation raw materials: collect the grape skin residue after fermentation of fresh dry red wine (Snake Dragon Ball), and dry red wine (Cabernet Sauvignon) that has been aged for 3 years (the aging container is a stainless steel tank and the temperature is 15°C). According to the volume ratio of 1:2, the raw materials for distillation are obtained.

[0053] (2) Install sieve plate: add a copper sieve plate with an aperture of 0.2cm at the upper 3 / 5 of the Charente pot;

[0054] (3) feeding: pour the dry red wine that needs to be distilled into the still pot, the volume is 50% of the still pot volume, put the grape skin residue on the sieve plate, and spread evenly;

[0055] (4) string steaming: do not intercept the head of the wine, the temperature in the kettle is controlled at 80 ° C, and the collection is stopped when the alcohol content...

Embodiment 3

[0059] A method for preparing grape distilled wine by mixing solid-liquid steam, the steps are as follows:

[0060] (1) Preparation of distillation raw materials: collect fresh dry red wine (Merlot) fermented grape skin residue, mix with dry red wine (Cabernet Sauvignon) aged for 4 years (the aging container is a stainless steel tank and the temperature is 16°C). , snake dragon ball 1:1) proportion by 1:2 volume ratio, obtain distillation raw material for subsequent use.

[0061] (2) Install sieve plate: add a copper sieve plate with an aperture of 0.2cm at the upper 3 / 5 of the Charente pot;

[0062] (3) Feeding: pour the dry red wine that needs to be distilled into the still pot, and the volume is 56% of the still pot volume, then place the grape skin residue on the sieve plate, and spread evenly;

[0063] (4) string steaming: do not intercept the head of the wine, the temperature in the kettle is controlled at 80 ° C, and the collection is stopped when the alcohol content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com