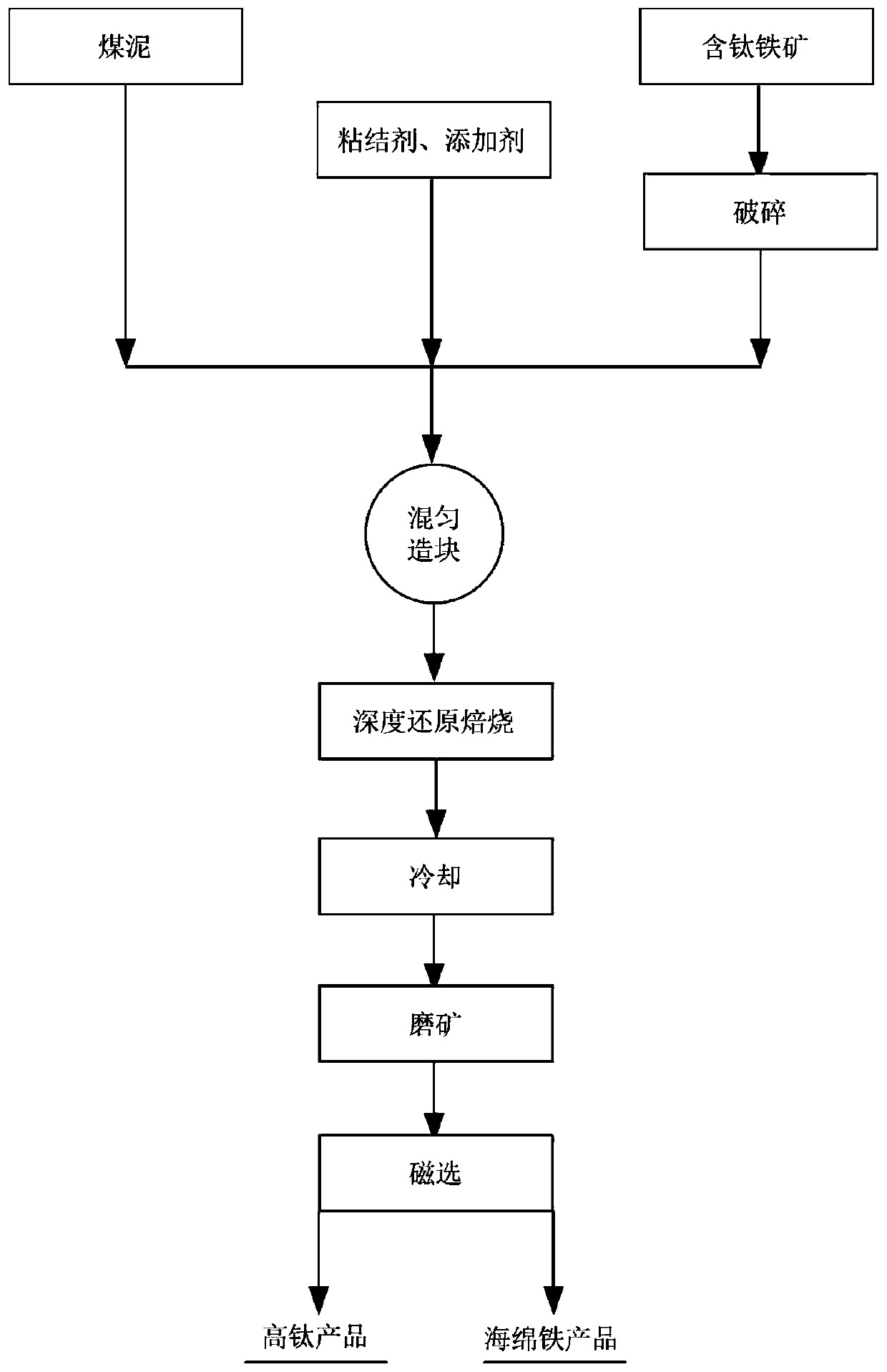

Method of producing high-titanium products and sponge iron using arentilla and coal slime as raw materials

A technology of ilmenite ore and sponge iron, applied in the field of comprehensive utilization of resources, can solve the problems of occupying land resources, high ash content, high moisture content, etc., and achieve the effects of saving coal resources, high economic value, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A ilmenite-containing ore with a particle size of 50cm~15cm has Fe grade of 40.28%, TiO 2 The grade is 8.25%. Using the method of the present invention, the mass ratio of ilmenite to coal slime is 1:0.32, the mass ratio to bentonite is 1:0.04, and the mass ratio to sodium carbonate and calcium carbonate is 1:0.015 and 1:0.06 respectively, and after mixing Press it into a block of 8cm×6cm×4cm, put the briquette into a roasting crucible, reduce and roast in a muffle furnace with a deep reduction temperature of 1260°C for 60 minutes to obtain a roasted product, and the roasted product is wet-ground after cooling, and the initial grinding The ore concentration is 60%, the first stage grinding product fineness -0.074 mm is 70%, and the second stage grinding fineness is -0.074 mm is 85%. Under the conditions of magnetic separation, a high-titanium product with a titanium dioxide content of 25.56% and a titanium dioxide recovery rate of 95.83% was obtained, and a sponge iron ...

Embodiment 2

[0016] A ilmenite-containing ore with a particle size of 50cm~10cm has Fe grade of 45.62%, TiO 2 The grade is 12.56%. Using the method of the present invention, the mass ratio of ilmenite to coal slime is 1:0.34, the mass ratio to bentonite is 1:0.05, and the mass ratio to sodium carbonate and calcium carbonate is 1:0.015 and 1:0.085 respectively, after mixing Pressed into a block of 8cm×6cm×4cm, put the briquette into a roasting crucible, reduce and roast in a muffle furnace with a deep reduction temperature of 1300°C for 50 minutes to obtain a roasted product, and the roasted product is wet-ground after cooling, and the initial grinding The ore mass concentration is 60%, the first-stage grinding product fineness -0.074 mm is 70%, the second-stage grinding fineness is -0.043 mm, which is 80%, and the products obtained by the two-stage grinding are all in a magnetic field with a strength of 1.8 kGs Under the condition of magnetic separation, a high-titanium product with a tit...

Embodiment 3

[0018] A ilmenite-containing ore with a particle size of 45cm~5cm has a Fe grade of 54.67%, TiO 2The grade is 14.86%. By adopting the method of the present invention, the mass ratio of ilmenite to coal slime is 1:0.38, the mass ratio to bentonite is 1:0.07, and the mass ratio to sodium carbonate and calcium carbonate is 1:0.015 and 1:0.10 respectively, after mixing Pressed into a block of 8cm×6cm×4cm, put the briquette into a roasting crucible, reduce and roast in a muffle furnace with a deep reduction temperature of 1350°C for 36 minutes to obtain a roasted product, and the roasted product is wet-ground after cooling, and the initial grinding The ore concentration is 60%, the first stage grinding product fineness -0.074 mm is 70%, the second stage grinding fineness is -0.043 mm is 80%, the products obtained by the two stage grinding are all under the condition of magnetic field strength of 2kGs Under magnetic separation, a high-titanium product with a titanium dioxide conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com