Beneficiation method for efficiently recovering copper and molybdenum associated with gold and rhenium from porphyry type copper-molybdenum deposit

A beneficiation method and technology of copper-molybdenum ore, which is applied in the beneficiation of molybdenum and copper, can solve the problems of weak secondary enrichment effect of mineralized foam, many impurities entrained in foam, and poor separation precision of copper and molybdenum, so as to reduce the trough drop Loss risk, improvement of grinding efficiency, effect of reducing grinding load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

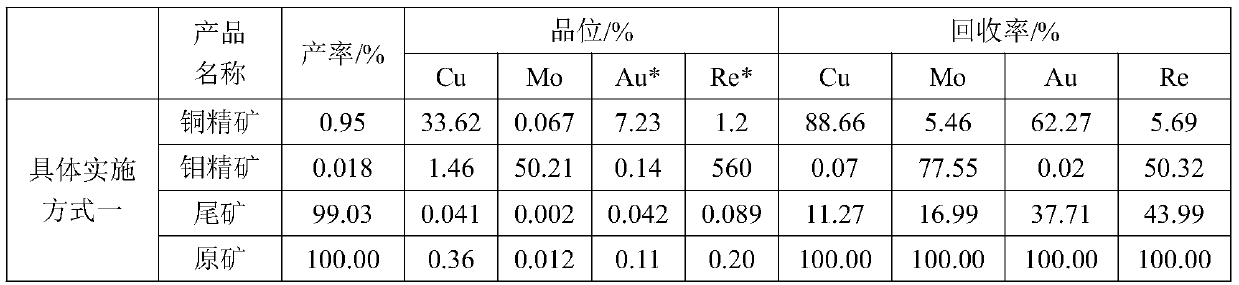

specific Embodiment approach 1

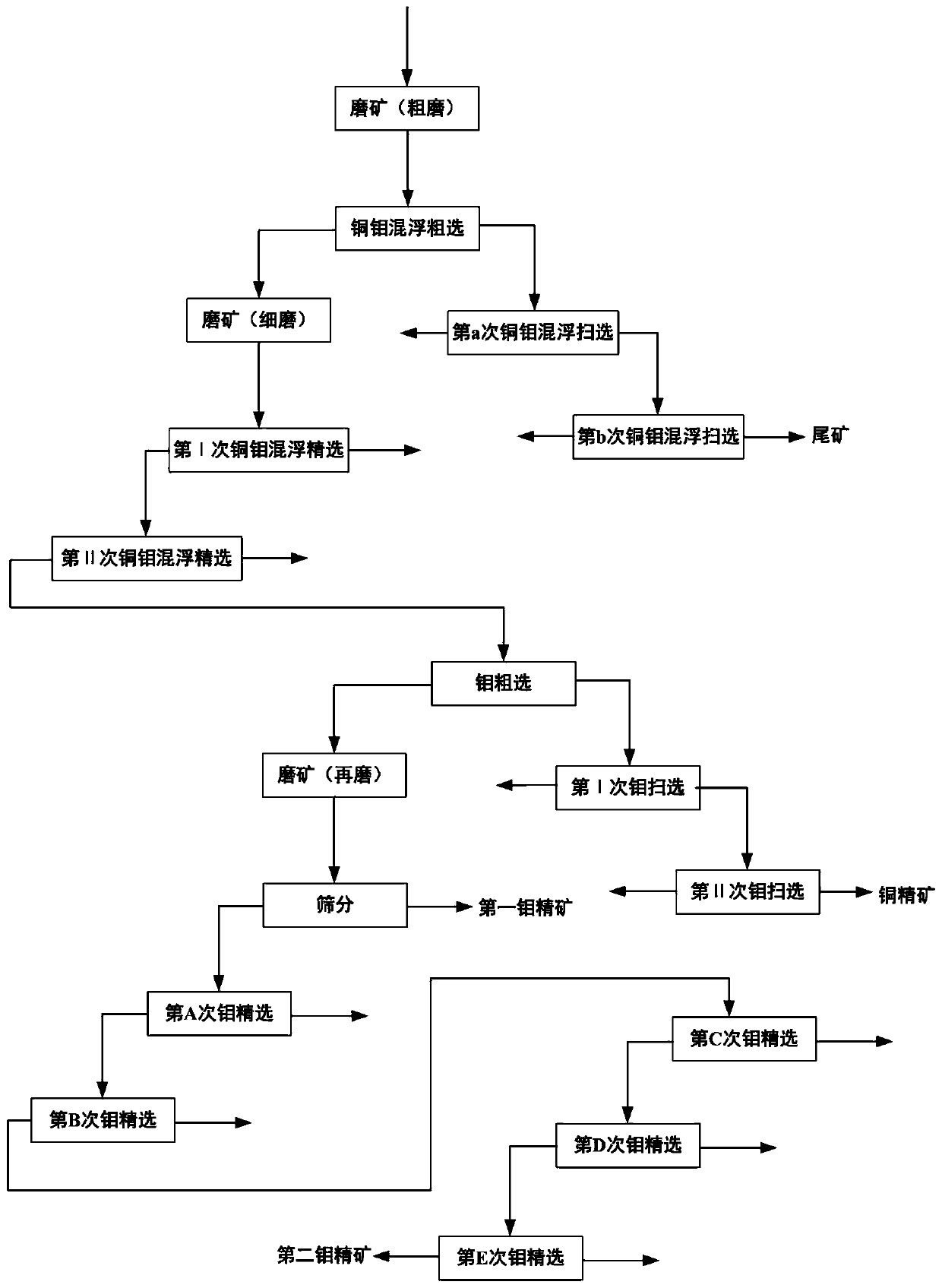

[0026]A method for efficiently recovering copper and molybdenum associated with gold rhenium from porphyry copper-molybdenum ore, comprising the following steps:

[0027] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness of -0.074mm particle size grade accounts for 55% of the total weight of the ore. During the grinding process, add 500g / t of lime, add water to adjust the slurry until the pH of the ore is 7. Obtain the ore grinding slurry for use;

[0028] Step 2. Add 100g / t of water glass, 80g / t of butyl xanthate, 10g / t of sulfonated kerosene, and 20g / t of methyl isobutyl carbinol to the grinding pulp obtained in step 1 in order to carry out copper-molybdenum mixing. Flotation roughing, copper molybdenum mixed flotation roughing time 3 ~ 6min, get copper molybdenum mixed flotation rougher concentrate and copper molybdenum mixed flotation rougher tailings, stand-by;

[0029] Step 3, grind the copper-molybdenum mixed flotation...

specific Embodiment approach 2

[0047] A method for efficiently recovering copper and molybdenum associated with gold rhenium from porphyry copper-molybdenum ore, comprising the following steps:

[0048] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness -0.074mm particle size grade accounts for 60% of the total weight of the ore. During the grinding process, add 800g / t of lime, add water to adjust the slurry until the pH of the slurry is 8. Obtain the ore grinding slurry for use;

[0049] Step 2. Add 200g / t of water glass, 100g / t of butyl xanthate, 15g / t of sulfonated kerosene, and 30g / t of methyl isobutyl carbinol to the grinding slurry obtained in step 1 in order to carry out copper-molybdenum mixing. Flotation roughing, copper molybdenum mixed flotation roughing time 3 ~ 6min, get copper molybdenum mixed flotation rougher concentrate and copper molybdenum mixed flotation rougher tailings, stand-by;

[0050] Step 3. Grind the copper-molybdenum mixed flota...

specific Embodiment approach 3

[0069] A method for efficiently recovering copper and molybdenum associated with gold rhenium from porphyry copper-molybdenum ore, comprising the following steps:

[0070] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness -0.074mm particle size grade accounts for 55-60% of the total weight of the ore. During the grinding process, add lime 500-800g / t, add water to adjust the slurry Until the pH of the pulp is 7-8, the grinding pulp is obtained and set aside;

[0071] Step 2. Add water glass 100-200g / t, butyl xanthate 80-100g / t, sulfonated kerosene 10-15g / t, methyl isobutyl carbinol 20- 30g / t, carry out copper-molybdenum mixed flotation roughing, copper-molybdenum mixed flotation roughing time 3 ~ 6min, get copper-molybdenum mixed flotation roughing concentrate and copper-molybdenum mixed flotation roughing tailings, stand-by;

[0072] Step 3, using a ball mill to grind the copper-molybdenum mixed flotation rougher concentrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com