NiTi alloy fiber concrete and preparation method thereof

A technology of alloy fiber and concrete, which is applied in the field of concrete, can solve the problems of low flexural strength and fatigue resistance, and easy brittle cracks, and achieve the effects of improving seismic ductility, enhancing resistance, and reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of NiTi alloy fiber concrete in the embodiment is specifically the following steps:

[0029] (1) Add cement, gravel, fly ash, silica fume, and slag into the mixer in proportion and stir for 2-3 minutes;

[0030] (2) Mix the water reducer and water in proportion and stir to form a mixed liquid, then add it to the mixer twice, add 50% of the mixed liquid for the first time, and add the remaining 50% of the mixed liquid for the second time, each time Stir for 1min to 2min after adding the mixture;

[0031] (3) Add the steel fiber and NiTi fiber into the stirring pot, load them evenly while stirring, finish adding within 1 minute, then stir for 3 minutes to 5 minutes, and add them to the mold. After molding and demoulding, the prepared test piece is Standard maintenance, the maintenance period is 28d; get NiTi alloy fiber concrete.

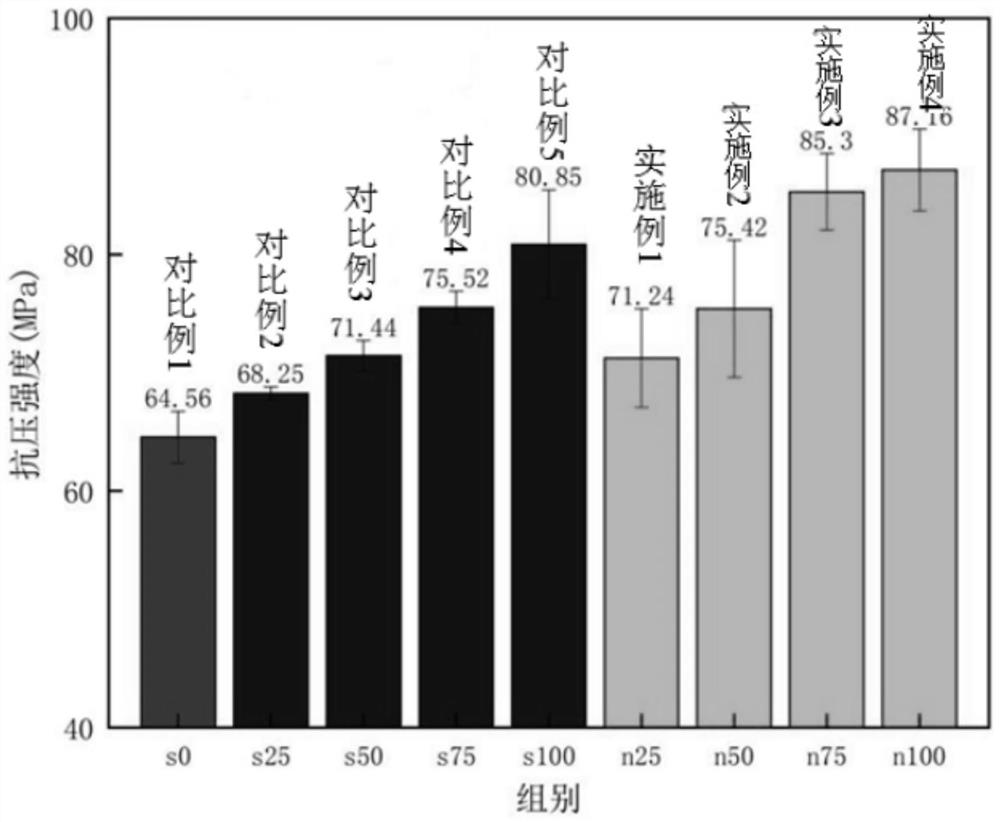

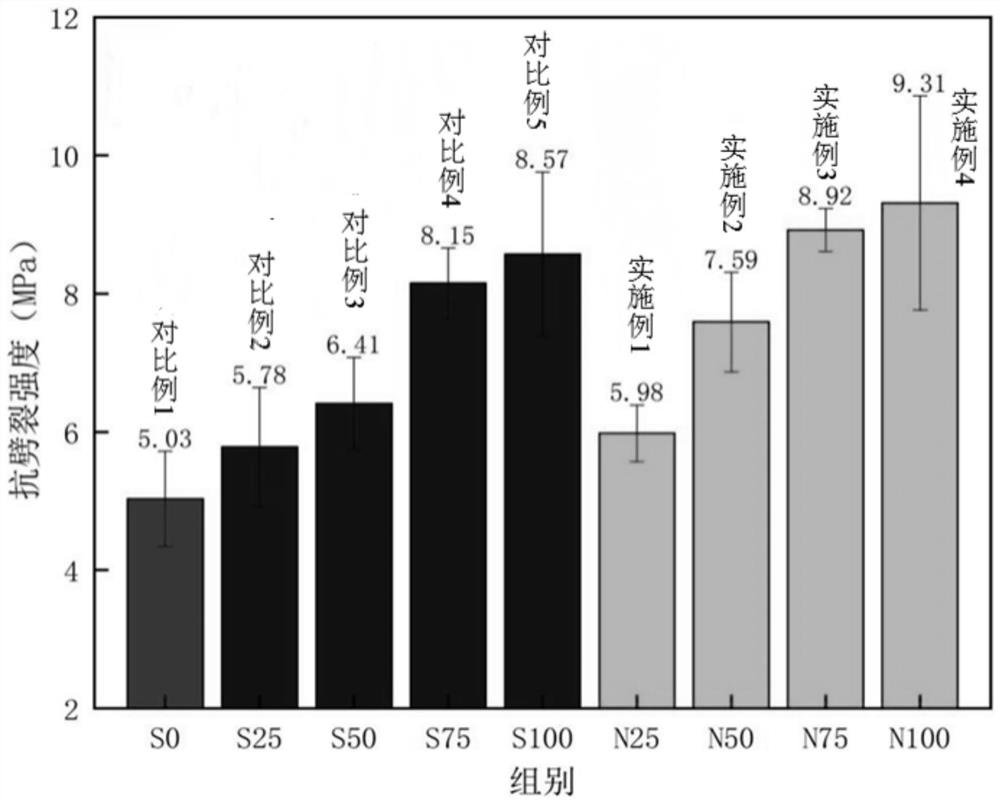

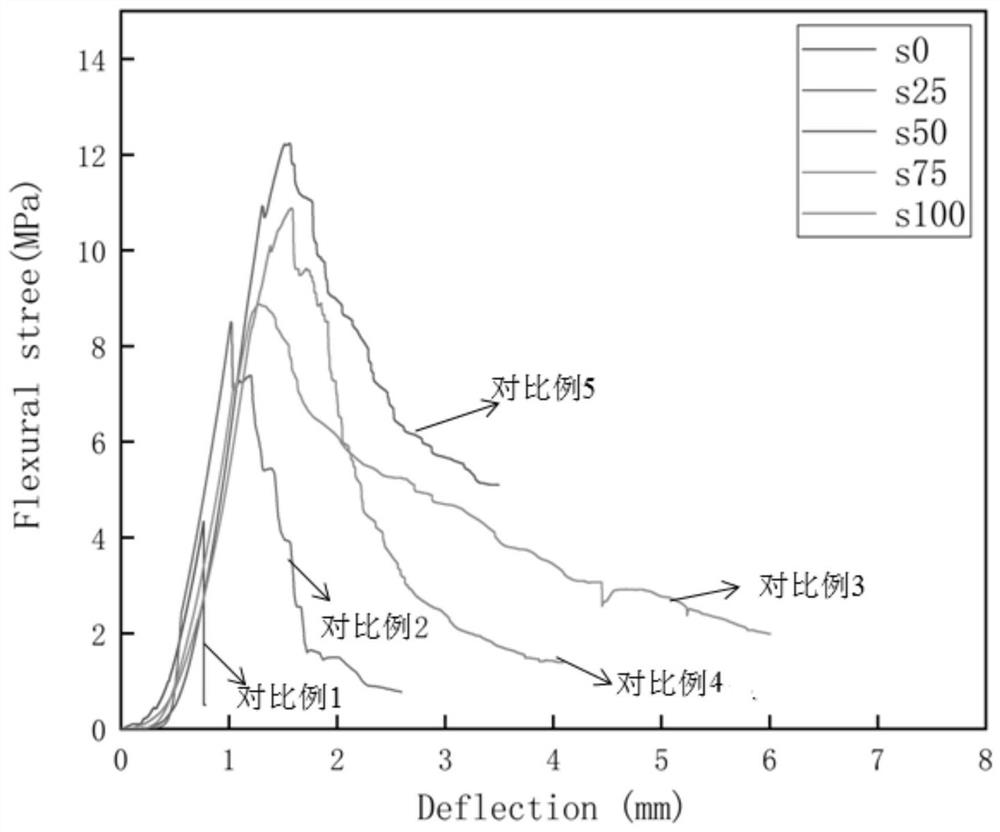

Embodiment 1

[0033] A NiTi alloy fiber concrete is formed by mixing the following raw materials by mass percentage: 350 parts of cement, 700 parts of river sand, 1050 parts of gravel, and 16.3 parts of NiTi alloy fiber (0.67% by mass percentage, volume fraction 0.25%), 62.5 parts of fly ash, 50 parts of slag, 37.5 parts of silica fume, 15 parts of water reducing agent, and 150 parts of water.

Embodiment 2

[0035] A NiTi alloy fiber concrete is formed by mixing the following raw materials by mass percentage: 350 parts of cement, 700 parts of river sand, 1050 parts of crushed stone, 32.6 parts of NiTi alloy fiber (mass percentage 1.33%, volume fraction 0.50%), 62.5 parts of fly ash, 50 parts of slag, 37.5 parts of silica fume, 15 parts of water reducing agent, and 150 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com