Sprayed concrete as well as preparation method and application thereof

A shotcrete and accelerator technology, applied in the field of highway engineering materials, can solve the problems of high rebound rate, waste of shotcrete material, low bond strength, etc. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

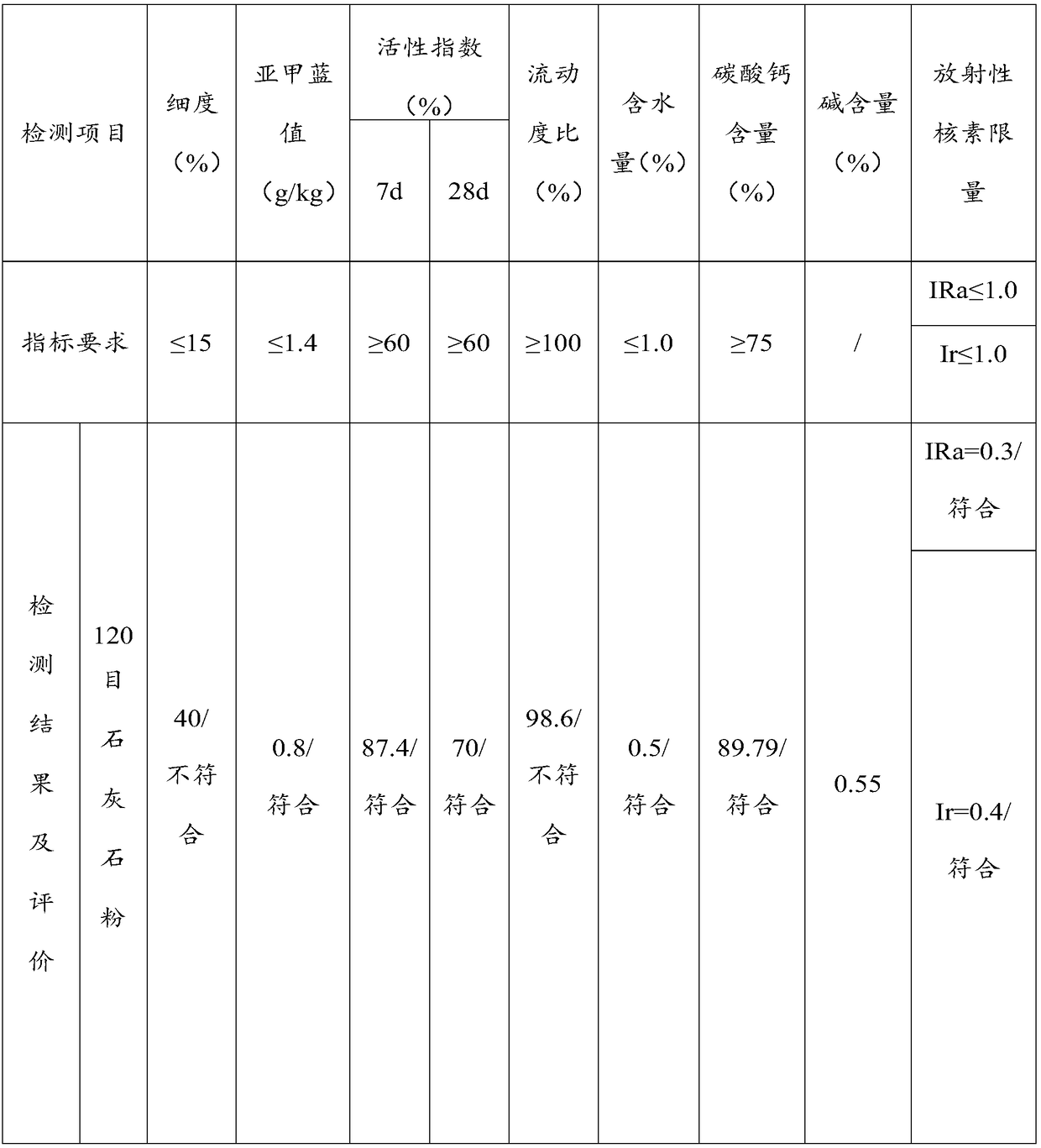

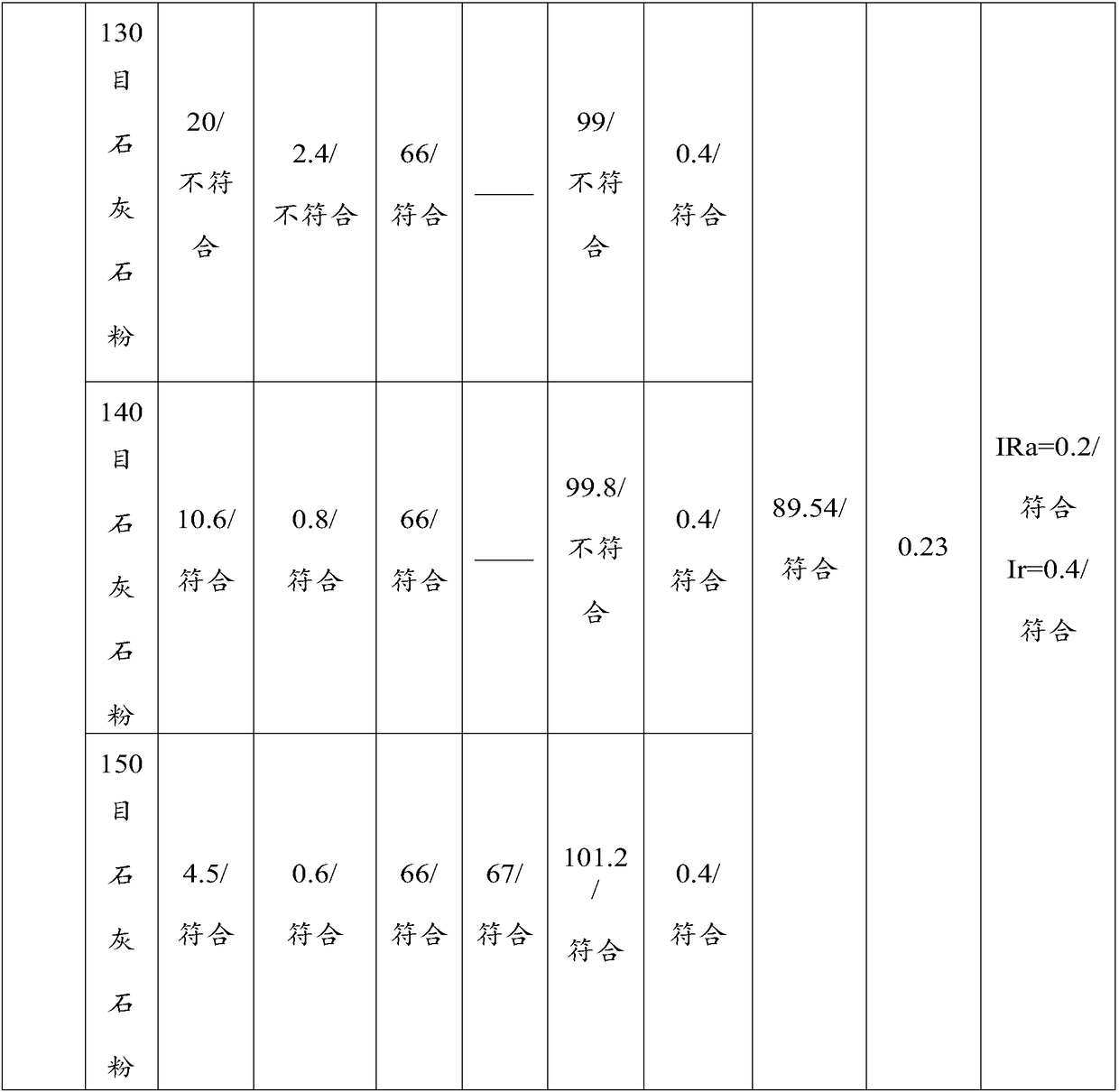

Image

Examples

preparation example Construction

[0071] The preparation method of sprayed concrete as above may further comprise the steps:

[0072] Mix and stir cement, limestone powder, crushed stone, sand, water reducing agent, quick-setting agent, tackifier and water to obtain shotcrete.

[0073] Sprayed concrete support for tunnels and large caverns shall be constructed by wet mix spraying method. The sprayed concrete support of small caverns and open-air projects can be constructed by the dry mixing method (semi-wet method) spraying method with an aggregate moisture content of 5% to 6%.

[0074] Preferably, the stirring time is 120-300s, preferably 150-200s.

[0075] Typical but non-limiting examples of stirring time are 120s, 130s, 140s, 150s, 160s, 170s, 180s, 190s, 200s, 250s or 300s.

[0076] Application of shotcrete as described above in the construction of tunnels, caverns, slopes and / or foundation pits. The design strength grade of limestone sprayed concrete should not be lower than C20; when it is used for e...

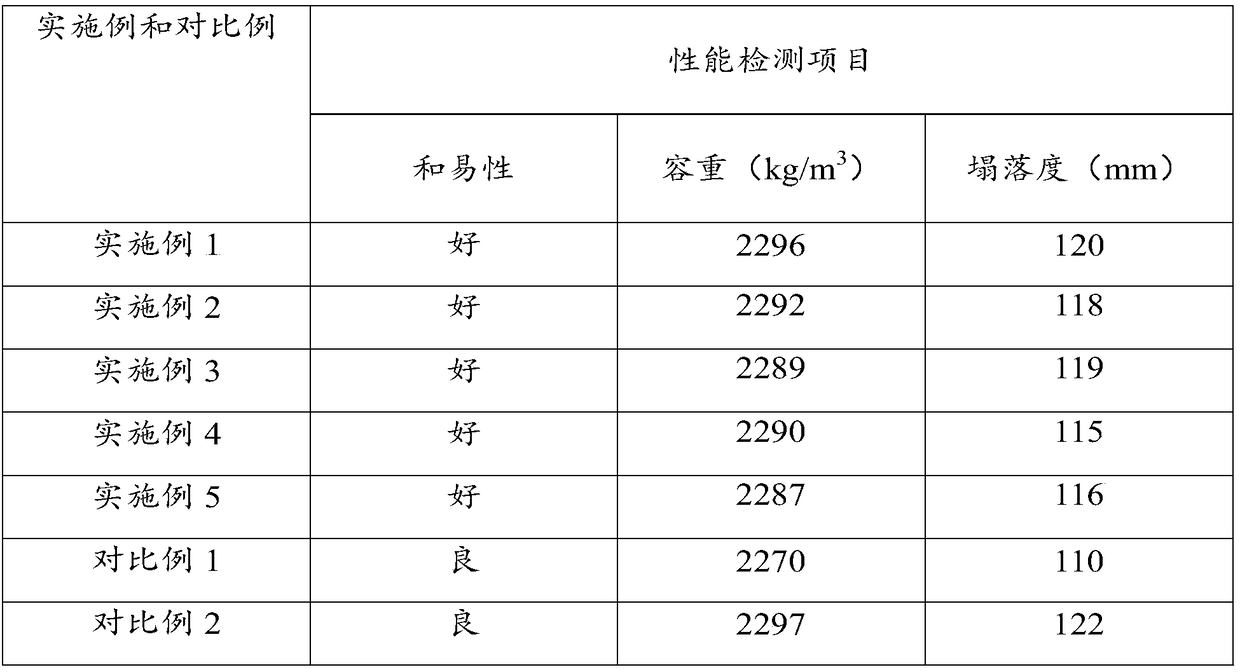

Embodiment 1

[0079] A shotcrete consisting, per cubic meter, principally of the following components by weight:

[0080] 320kg of cement, 80kg of limestone powder, 759kg of crushed stone, 965kg of sand, 2.4kg of polycarboxylate superplasticizer, 24kg of Red Star Type I accelerator, 0.1kg of methylcellulose and 176kg of water.

[0081] Among them, the limestone powder has a mesh number of 150 mesh and a fineness of 4.5%;

[0082] The sand rate of limestone powder concrete for highway engineering is 56%;

[0083] The water-binder ratio of limestone powder concrete for highway engineering is 0.44;

[0084] The preparation method of described sprayed concrete comprises the following steps:

[0085] To prepare limestone powder with a mesh number of 150 and a fineness of 4.5%, mix cement, limestone powder, crushed stone, sand, polycarboxylate superplasticizer, Red Star Type I quick-setting agent, methylcellulose and water in a double-bed Mix in a shaft-forced mixer for 150s to obtain shotcret...

Embodiment 2

[0087] A shotcrete consisting, per cubic meter, principally of the following components by weight:

[0088] 310kg of cement, 85kg of limestone powder, 750kg of gravel, 970kg of sand, 2.2kg of polycarboxylate superplasticizer, 22kg of 782 quick-setting agent, 0.09kg of ethyl cellulose and 180kg of water;

[0089] Among them, the limestone powder has a mesh number of 150 mesh and a fineness of 4.5%;

[0090] The preparation method of described sprayed concrete comprises the following steps:

[0091] Prepare limestone powder with 150 meshes and 4.5% fineness, mix cement, limestone powder, crushed stone, sand, polycarboxylate superplasticizer, 782 quick-setting agent, ethyl cellulose and water in a double-horizon shaft Mix in a forced mixer for 130s to obtain shotcrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com