Enhanced type cement and production method thereof

A production method and enhanced technology, applied in the field of building materials, can solve problems such as troublesome construction, affecting project quality, and incompatibility between water reducing agent and cement, and achieve the effects of improving quality, simplifying application, and being suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The enhanced cement in this embodiment is made by mixing 42.5 grade ordinary Portland cement and powdered naphthalene water reducer in a weight ratio of 100:0.7.

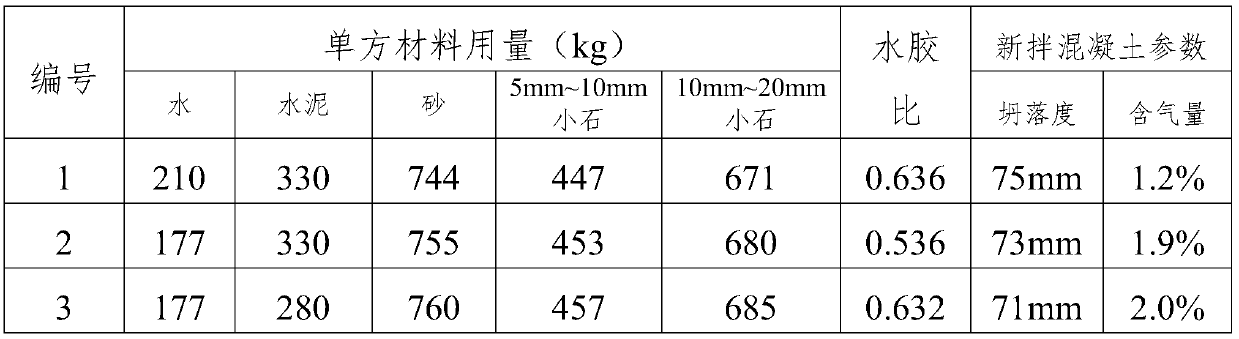

[0023] Formed concrete specimens were compared with the use effect of 42.5 grade ordinary Portland cement before and after adding powder naphthalene superplasticizer. Table 1 is the concrete mix parameters, and Table 2 is the test results of compressive strength. The cement used in No. 1 is 42.5 grade ordinary Portland cement, and the cement used in No. 2 and No. 3 is the enhanced cement prepared in Example 1.

[0024] Table 1 Concrete mix ratio related parameters

[0025]

[0026] Table 2 Concrete compressive strength test results

[0027]

[0028] It can be seen from Table 1 and Table 2 that under the same slump condition, the use of enhanced cement mixed with naphthalene-based water reducer can significantly reduce water consumption. Comparing the compressive strength results of No. 2 and No. 1, u...

Embodiment 2

[0030] The enhanced cement in this embodiment is made by mixing 32.5 grade ordinary Portland cement and powdered naphthalene water reducer in a weight ratio of 100:0.7.

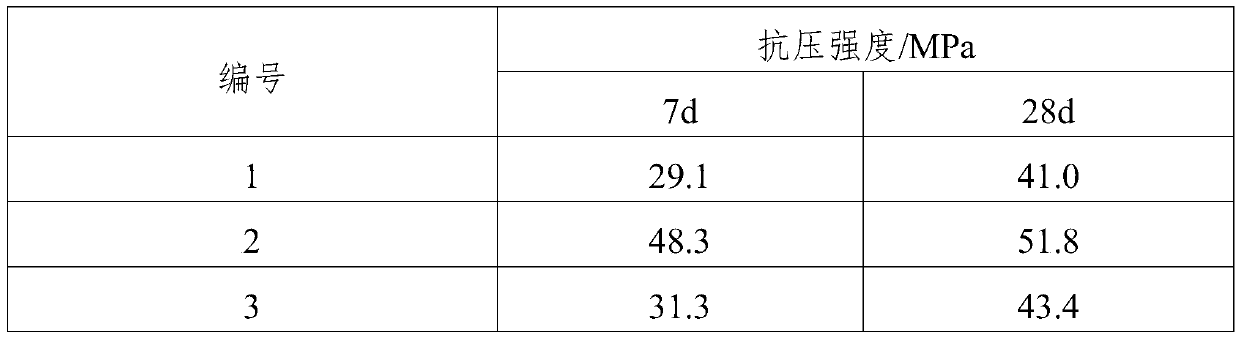

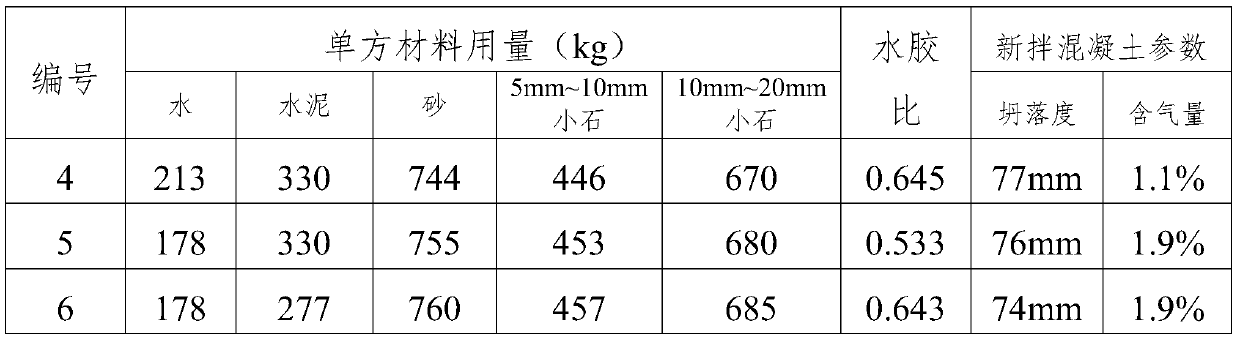

[0031] Formed concrete specimens, comparing the effect of 32.5 grade ordinary Portland cement before and after adding powder naphthalene superplasticizer. Table 3 is the concrete mix parameters, and Table 4 is the test results of compressive strength. The cement used in No. 4 is 32.5 grade ordinary Portland cement, and the cement used in No. 5 and No. 6 is the enhanced cement prepared in Example 2.

[0032] Table 3 Concrete mix ratio related parameters

[0033]

[0034] Table 4 concrete compressive strength test results

[0035]

[0036] It can be seen from Table 3 and Table 4 that under the same slump conditions, the use of enhanced cement mixed with naphthalene-based water reducer can significantly reduce water consumption. Comparing the compressive strength results of No. 5 and No. 4, under the sa...

Embodiment 3

[0038] The enhanced cement in this embodiment is made by mixing 42.5 grade ordinary Portland cement and powder polycarboxylate water reducer with a weight ratio of 100:0.16.

[0039] Formed concrete specimens, comparing the effect of 42.5 grade ordinary Portland cement before and after adding powder polycarboxylate superplasticizer. Table 5 is the concrete mix parameters, and Table 6 is the test results of compressive strength. The cement used in No. 7 is 42.5 grade ordinary Portland cement, and the cement used in No. 8 and No. 9 is the enhanced cement prepared in Example 3.

[0040] Table 5 Concrete mix ratio related parameters

[0041]

[0042] Table 6 concrete compressive strength test results

[0043]

[0044]It can be seen from Table 5 and Table 6 that under the same slump conditions, the use of enhanced cement mixed with powder polycarboxylate water reducer can significantly reduce water consumption. Comparing the compressive strength results of No. 8 and No. 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com