High strength silica powder concrete and construction technology

A concrete and high-strength technology, applied in the field of construction engineering, can solve the problems of small water-to-binder ratio, large amount of cement, and difficulty in bleeding, and achieve the effects of reducing adiabatic temperature rise, saving construction, and simplifying construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

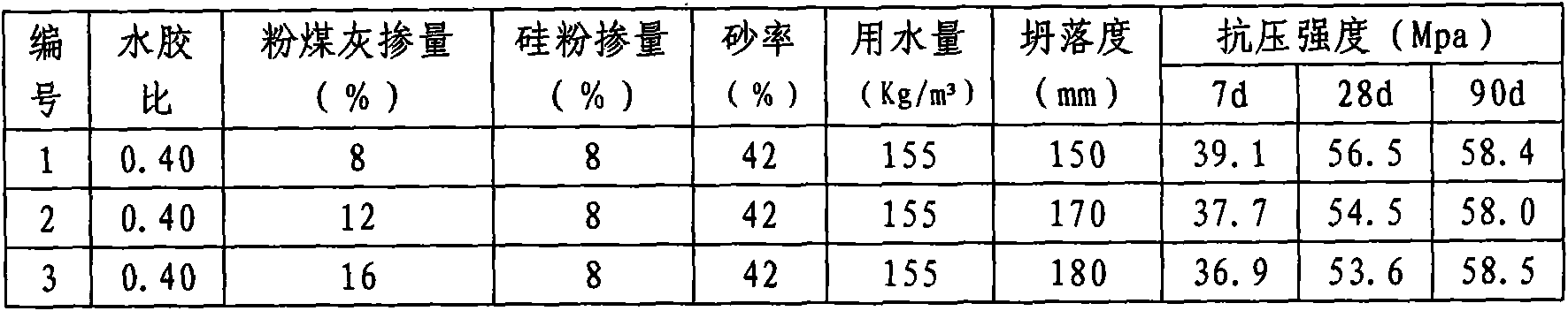

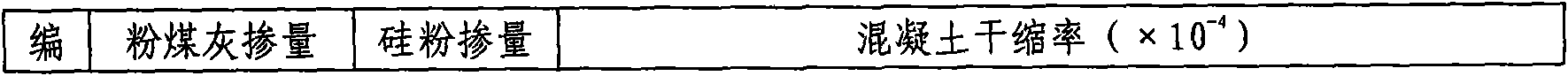

Examples

Embodiment Construction

[0034] Below we will further illustrate in combination with specific embodiments.

[0035] The Pubugou Hydropower Station flood discharge tunnel project is located on the left bank of the Pubugou Hydropower Station, and is one of the main flood discharge structures of the Pubugou Hydropower Station. The flood discharge tunnel is arranged in the granite body on the left bank, the tunnel line is straight, and the azimuth angle is N60°30′W. The flood tunnel consists of three parts: the entrance, the tunnel and the exit. The maximum discharge flow of the flood discharge tunnel is 3412m 3 / s, the maximum velocity is 42m / s. Due to the high elevation of the spillway, the Pubugou Reservoir mainly uses the spillway tunnel for flood discharge when the water level is low. The flood discharge tunnel has a huge discharge capacity and a very large flood discharge power. When the spillway tunnel is in operation, the high-speed water flow in the tunnel will have a strong abrasion and cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com