Construction method of low-cement fully-regenerated rock-fill concrete

A construction method and regenerative pile technology, applied in the field of building materials, can solve the problems of large amount of land occupation and processing costs, occupation of land resources, etc., and achieve the effects of saving labor and machine costs, reducing cement consumption, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

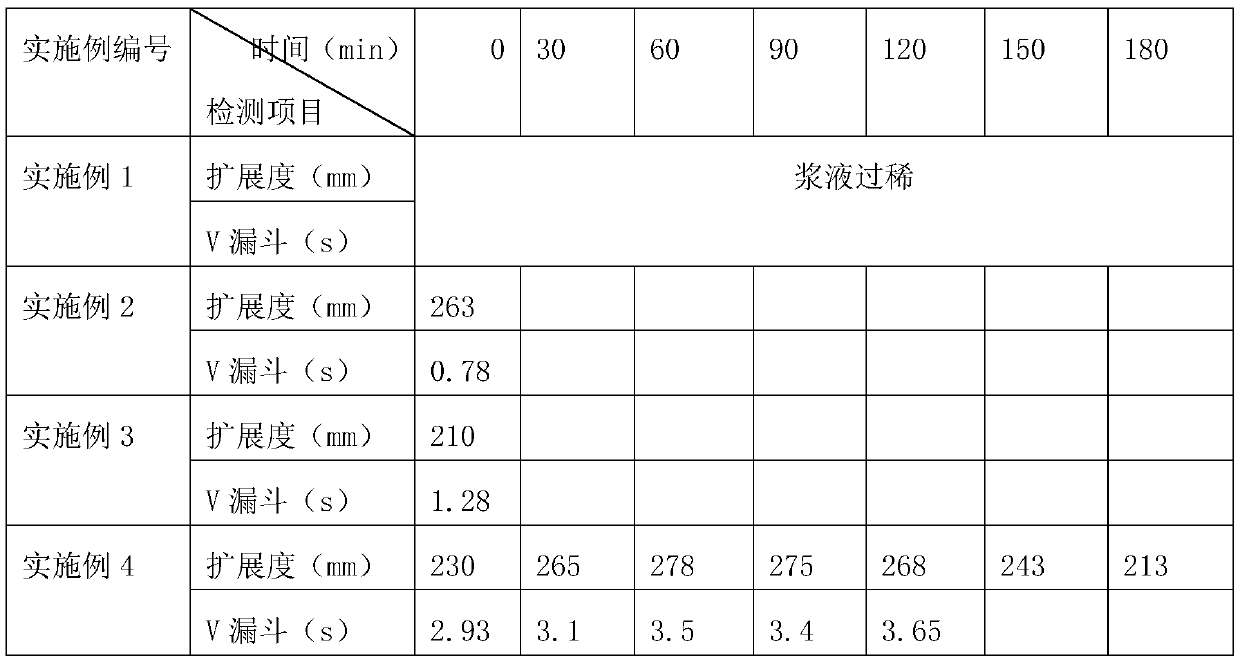

[0049] Example 1

[0050] A pure pulp, including the following components by mass:

[0051] 247.9g water, 232.5g cement, 427.9g regenerated fine powder, 2.65g admixture.

[0052] The preparation method of pure pulp is as follows:

[0053] In the pure slurry mixer, under normal temperature conditions, add 232.5g of cement and 427.9g of regenerated fine powder, and start mixing according to the machine program. In 5 seconds, add 247.9g of water and 2.65g of additives. The admixture is uniformly dissolved in water in advance. The pure slurry mixture is obtained and tested. Test items and data are shown in Table 1.

Example Embodiment

[0054] Example 2

[0055] A pure pulp, including the following components by mass:

[0056] Water 204g, cement 273.5g, recycled fine powder 503.4g, admixture 2g.

[0057] The preparation method of pure pulp is as follows:

[0058] In the pure slurry mixer, under normal temperature conditions, add 273.5 cement, 503.4gg regenerated fine powder, start mixing according to the machine program, add 204g water and 2g additives in 5 seconds. The admixture is uniformly dissolved in water in advance. The pure slurry mixture is obtained and tested. Test items and data are shown in Table 1.

Example Embodiment

[0059] Example 3

[0060] A pure pulp, including the following components by mass:

[0061] Water 202.5g, cement 182.4g, regenerated fine powder 575.3g, admixture 4.17g, sodium gluconate 0.18g.

[0062] The preparation method of pure pulp is as follows:

[0063] In a pure slurry mixer, under normal temperature conditions, add 182.4g of cement and 575.3g of regenerated micropowder, and start mixing according to the machine program. In 5 seconds, add 202.5g of water, 4.17g of additives, and 0.18g of sodium gluconate. The admixture and sodium gluconate are uniformly dissolved in water in advance. The pure slurry mixture is obtained and tested. Test items and data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com