Device for reducing water ratio of sludge

A technology of moisture content and sludge, applied in the field of resource treatment, can solve the problems of reducing the moisture content of sludge, the ability of moisture and heavy metals to decrease, and the degree of sludge moisture reduction to be different, and to achieve the effect of saving cement consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

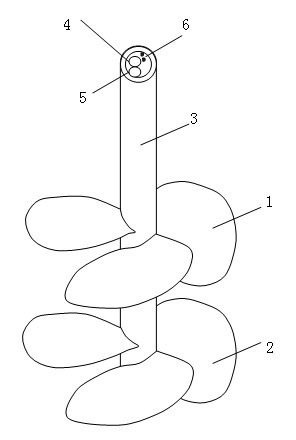

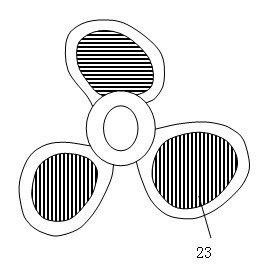

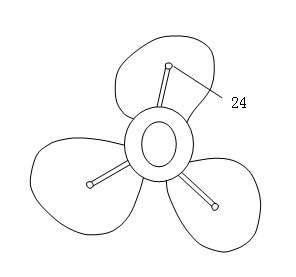

[0022] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 As shown, a device for reducing moisture content is composed of an upper screw blade 1, a lower screw blade 2, a hollow rotating shaft 3, and a drainage pipe 4. The shape of the upper and lower blades is similar to that of a propeller, and the lower screw blade A shallow groove is opened on the upper side of the blade, and a rubber pad 21, a filter cloth 22 and a thick steel bar grate 23 are successively installed on the shallow groove, see Figure 4 . Such as figure 2 , image 3 As shown, a shallow groove is provided on the lower side of the lower blade, so that the cement spray nozzle 24 is arranged in the shallow groove on the lower surface. The lower side of the upper helical blade is provided with shallow grooves, and rubber pads and conductive plates 11 are installed on the shallow grooves, see Figure 5 . Described transmission shaft 3 is a hollow steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com