Solidified soil stirring box for municipal construction

A technology for consolidating soil and mixing boxes, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve the problem that the hardness and slump cannot meet the design requirements, the cost of concrete pouring is high, and it cannot be compacted, etc. problems, to achieve the effect of reducing later risks, high compactness, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

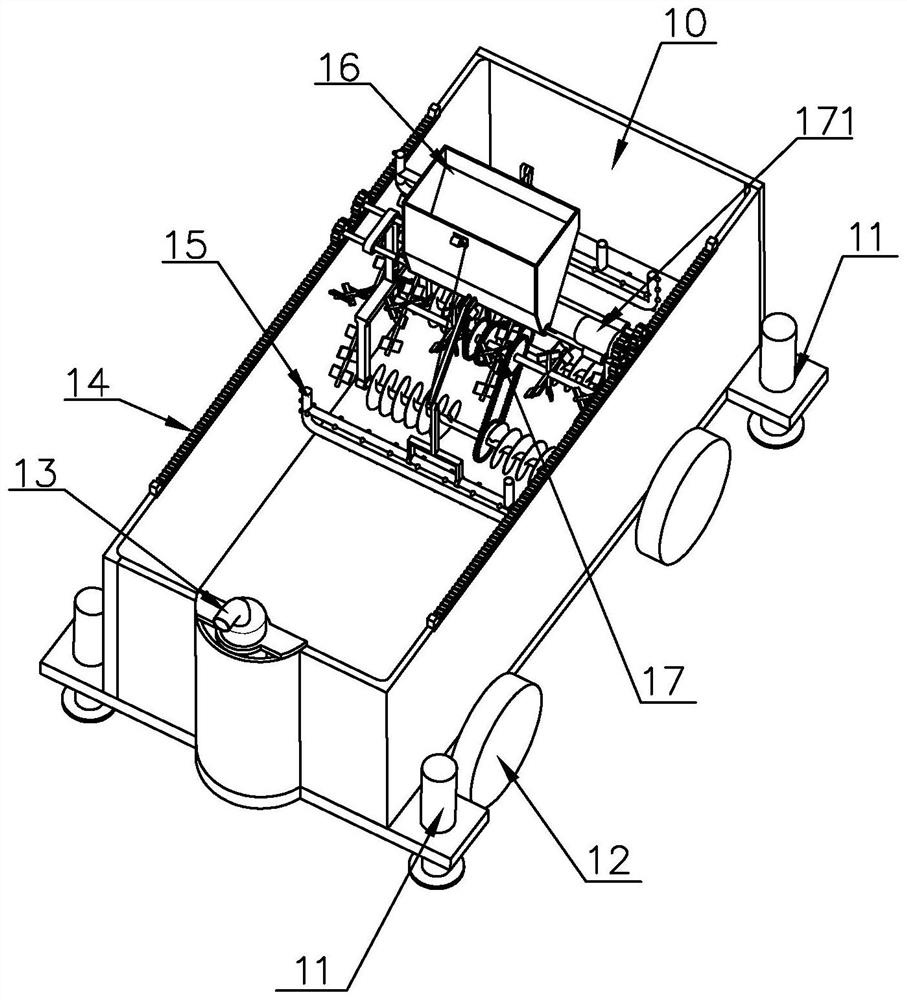

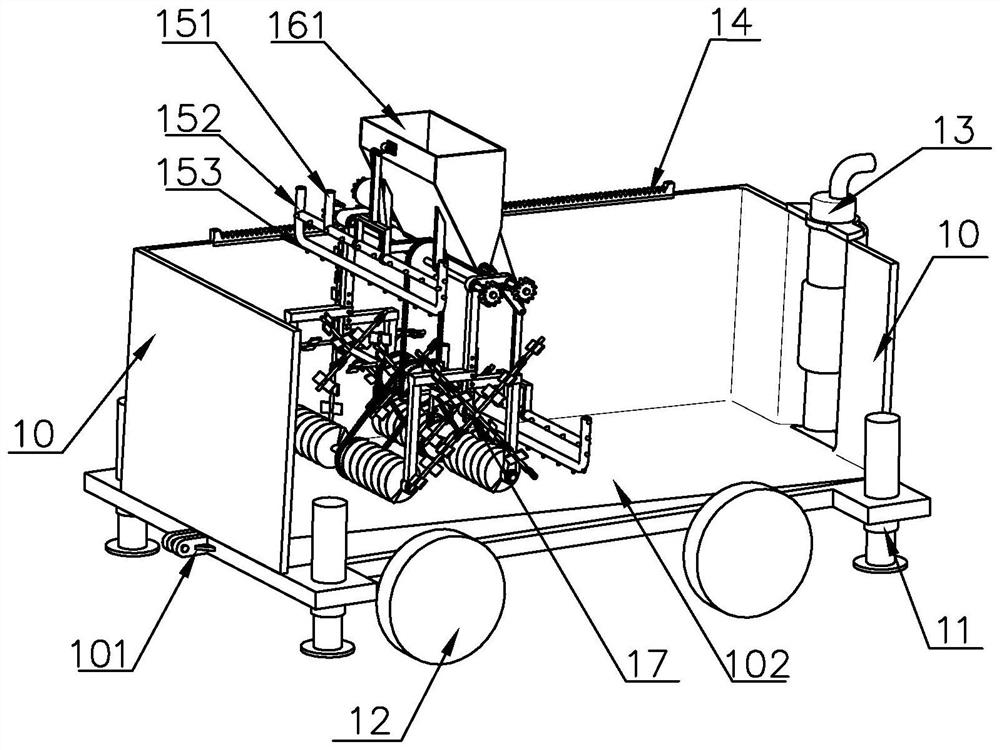

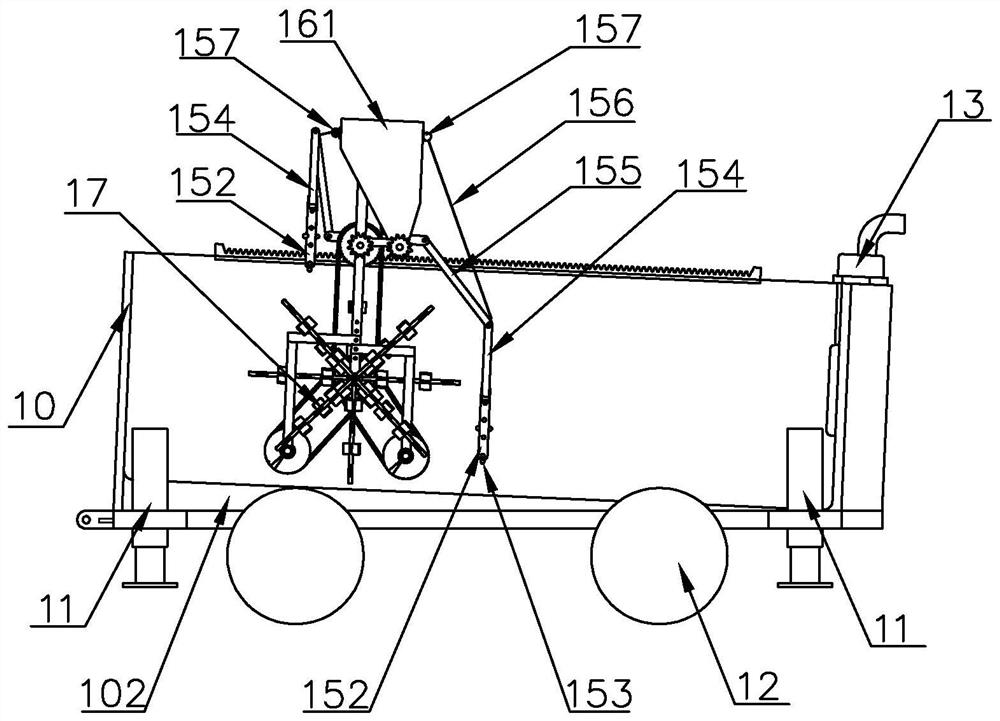

[0024] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0025] A consolidated soil mixing box for municipal construction, comprising a box body 10, a hydraulic support leg 11, a tire 12, a sludge pump 13, a rack 14, a cleaning mechanism 15, an automatic feeding mechanism 16, a stirring mechanism 17, and a bottom plate 102. A sludge pump 13 is provided on one side of the box body 10, a base plate 102 is provided below the box body 10, four sets of hydraulic legs 11 are provided on both sides of the base plate 102, a number of tires 12 are provided on both sides of the base plate 102, and a bottom plate 102 is provided above the box body 10. There are two racks 14, the racks 14 are provided with a stirring mechanism 17, the top of the stirring mechanism 17 is provided with an automatic feeding mechanism 16, and the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com