Backpack and components therefor

a technology for backpacks and components, applied in the field of backpacks and to backpack shoulder harnesses and hip harnesses, can solve the problems of difficulty in designing a back pack, general impracticality of cost for tailoring packs, hip harnesses, shoulder harnesses and frame elements to suit individuals, etc., to reduce chafing of an by their edges, strong resist coplanar flexing forces, and reduce bunching or edge curling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

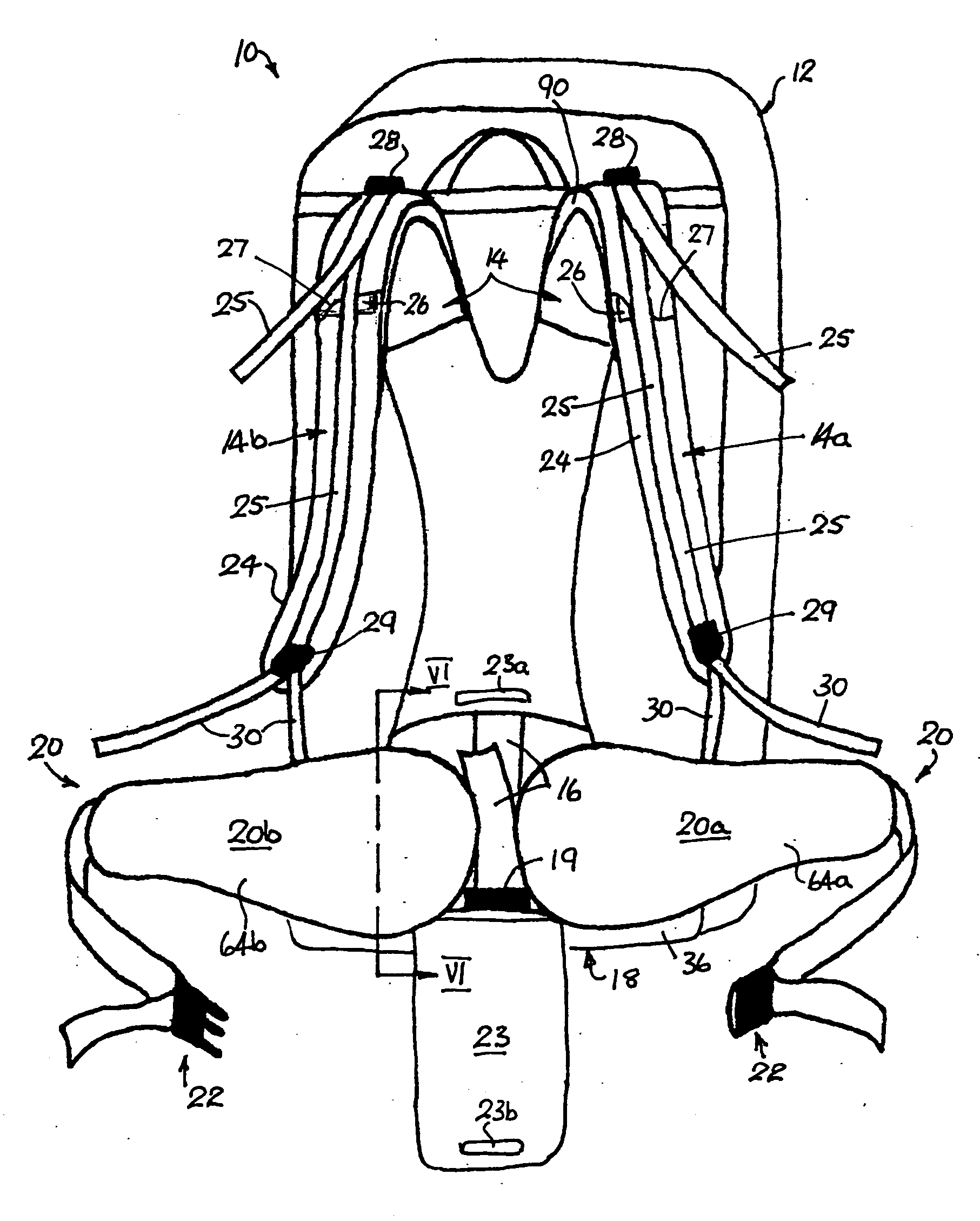

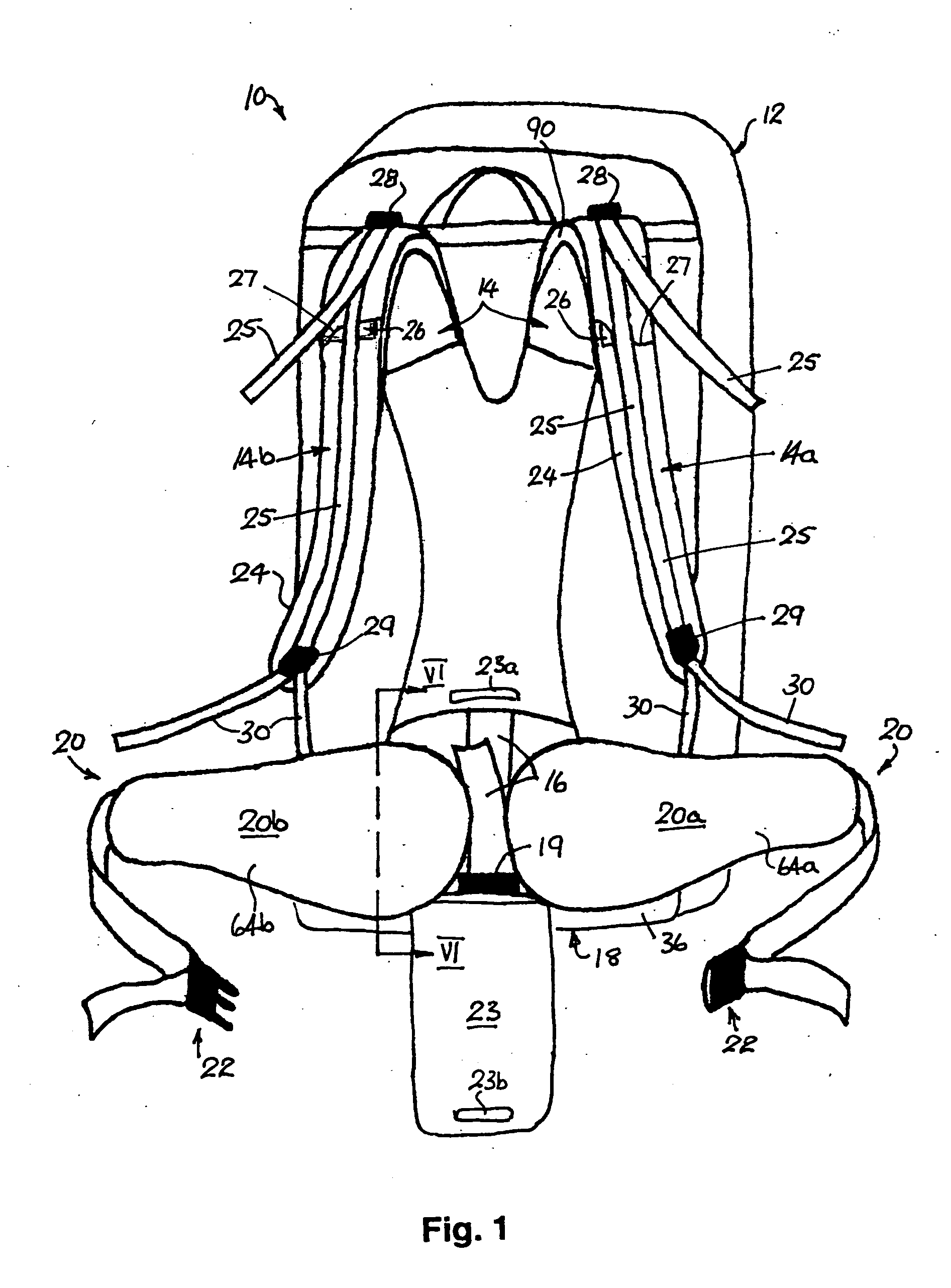

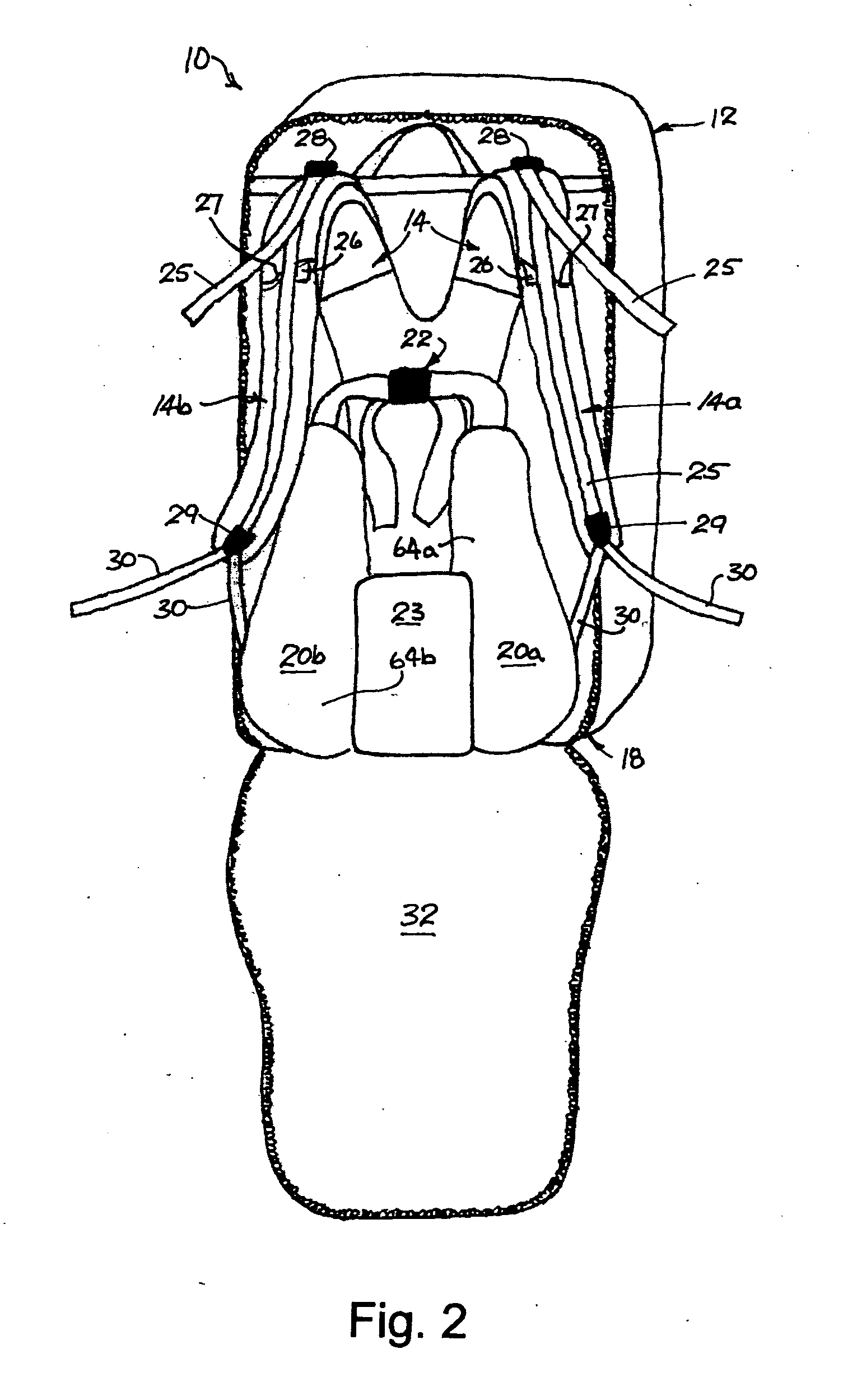

[0027] With reference to FIG. 1, the backpack 10 of the chosen example has a load-bag 12, a Y-shape shoulder harness 14, having left and right padded shoulder strap assemblies 14a and 14b and a common tail 16 that is adjustably secured to the base 18 of the pack by an anchor buckle 19, and a hip harness 20 comprised of (i) separate left and right side segments 20a and 20b pivotally attached to pack 10 near base 18 and (ii) waist buckle means 22. The front faces of segments 20a and 20b are covered by pads 64a and 64b (respectively, which will be described below. An optional lumbar flap 23 may be used to cover buckle 19 and shoulder harness tail 16 when the pack is worn. One end of flap 23 is sewn to base 18 so that the opposite end can be raised and attached by mating Velcro™ patches 23a and 23b to the front of pack 10.

[0028] Each strap assembly 14a and 14b of shoulder harness 14 essentially comprises (i) an elongated padded body 24 arranged to extend over the upper back and respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com