PCB appearance on-line maintenance device and maintenance method

A PCB board and appearance technology, which is applied in the field of PCB appearance maintenance equipment, can solve the problems of unfavorable industrialized mass production of PCB boards, slow maintenance speed, and high labor costs, so as to improve product processing efficiency and quality, reduce labor intensity, and mechanization degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

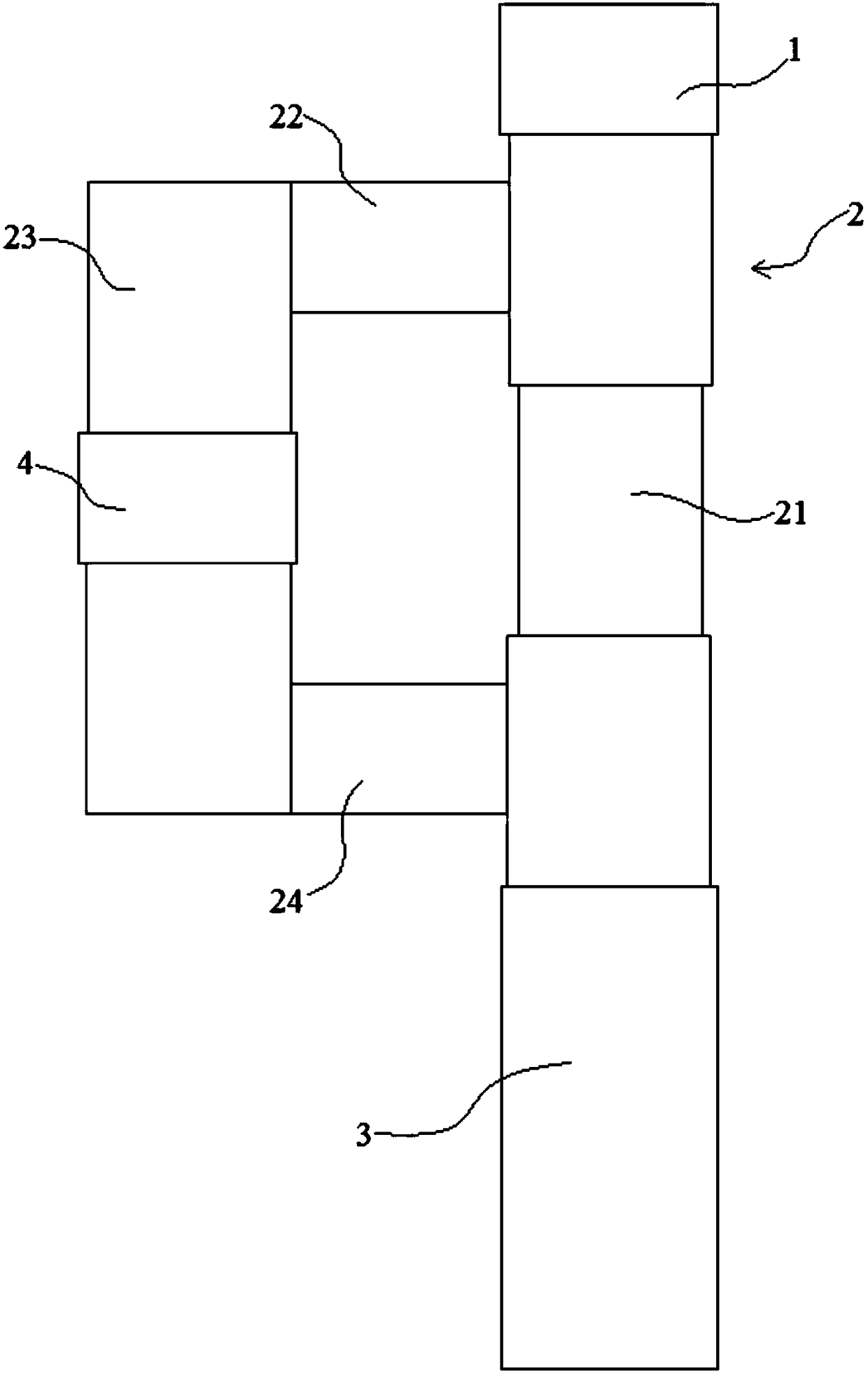

[0024] This embodiment provides an online maintenance device for PCB appearance, which is used for automatic inspection and repair of PCB appearance. The online maintenance equipment for PCB appearance is as follows: figure 1 As shown, it includes an online AOI machine 1 connected in sequence, an annular inspection unit 2 and a browning line 3, and the annular inspection unit 2 includes an endless conveyor belt for transferring PCB boards and an automatic conveyor belt connected to the endless conveyor belt. Overhaul machine 4.

[0025] Specifically, as shown in the figure, the endless conveyor belt includes a first conveyor belt 21, a second conveyor belt 22, a third conveyor belt 23 and a fourth conveyor belt 24 connected in sequence, and one end of the fourth conveyor belt 24 It is connected with the third conveyor belt 23 and the other end is connected with the first conveyor belt 21 to form a closed endless conveyor belt structure. At the same time, one end of the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com