Automobile accessory surface electrophoretic paint treatment device

A technology for auto parts and processing devices, applied in the direction of electrophoretic plating, electrolytic coating, electrolytic process, etc., can solve the problems of increasing workload, prolonging drying time, reducing the quality of auto parts, etc., to avoid handling and fixing, and speed up stirring Efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

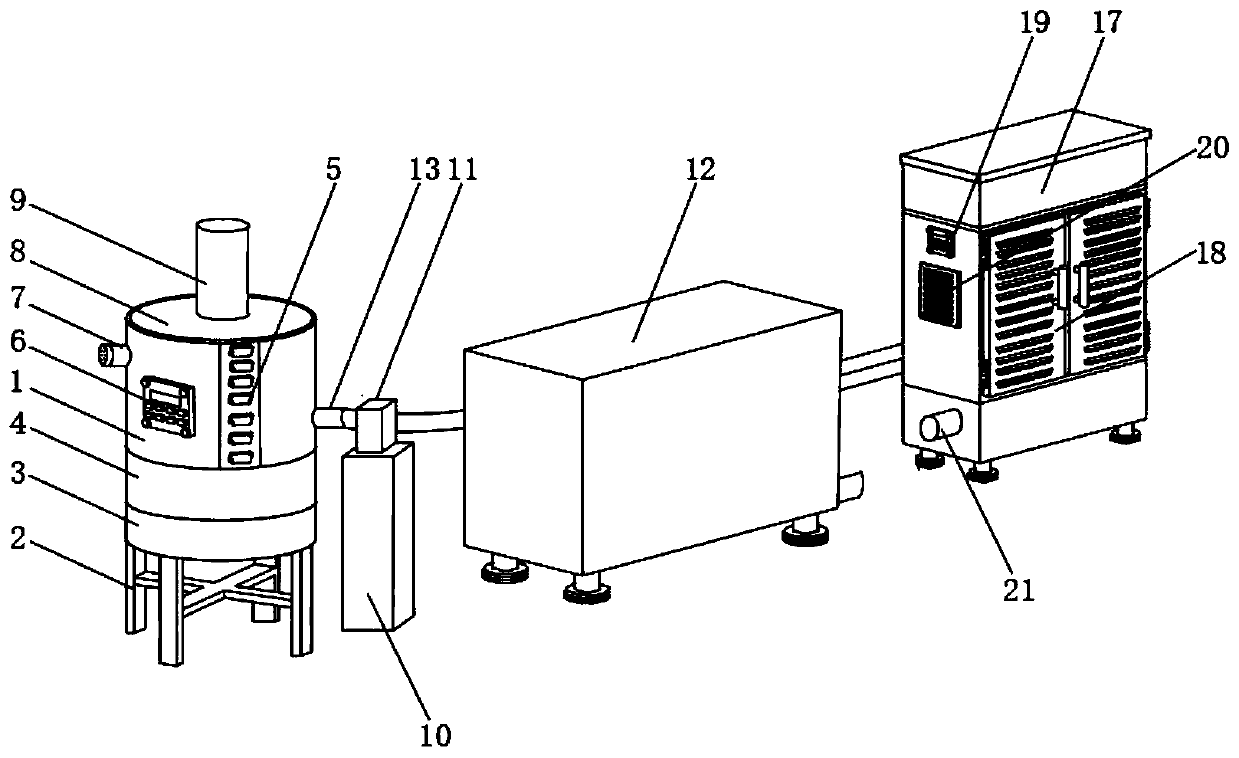

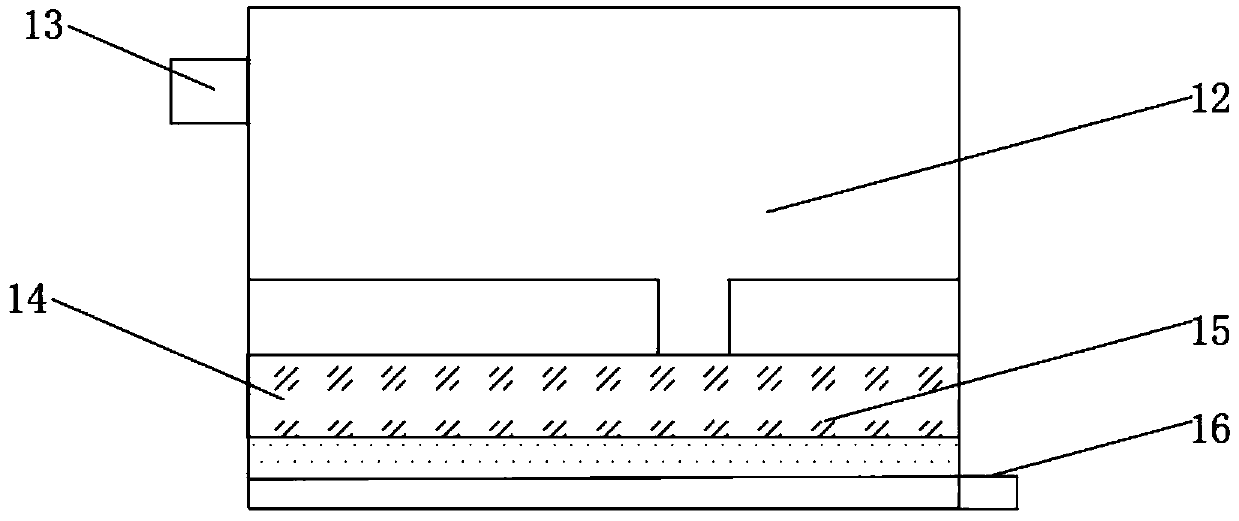

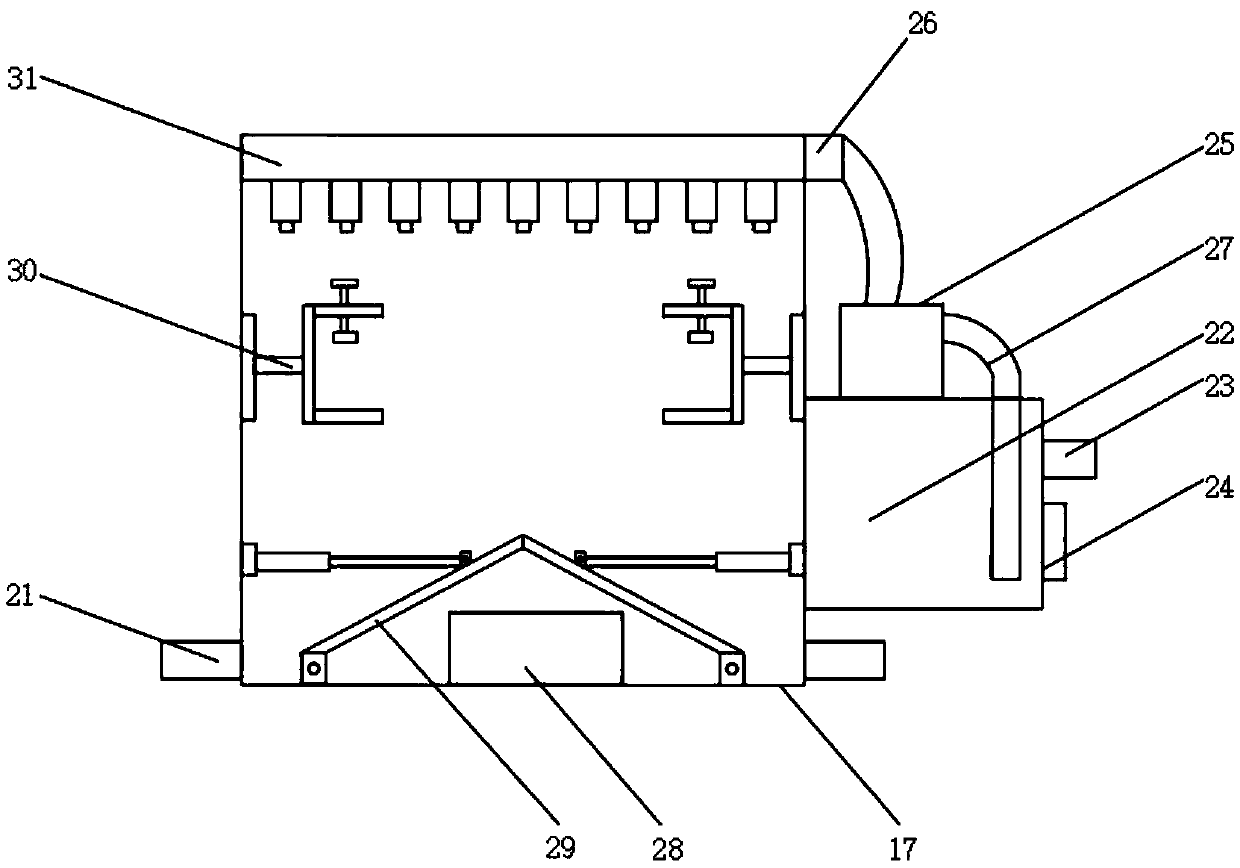

[0032] see Figure 1-9 , in an embodiment of the present invention, an electrophoretic paint treatment device for the surface of auto parts, comprising a mixing bucket 1. The inside of 1 is provided with a first stirring device 4 near the upper position of the sound-absorbing layer 3, and the front surface of the mixing bucket 1 is provided with an observation window 5, and the front surface of the mixing bucket 1 is fixedly installed on the side close to the observation window 5. The first control switch 6, and one side of the mixing bucket 1 is provided with a first water inlet 7, the upper surface of the mixing bucket 1 is rotated and installed with a bung 8, and the upper surface of the bung 8 is embedded with a second stirring device 9, through Set the mixing tank 1 to fully stir the electrophoretic paint to avoid shrinkage caused by uneven stirring, open the bucket cover 8 to add the electrophoretic paint, cover the bucket cover 8, add water through the first water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com