Solid mercury with high content

A technology with a mass content of 5%-35% zn, applied in the field of alloy materials, can solve the problems of affecting the environmental protection effect, difficult lamp-making process, poor low-temperature start-up performance, etc., and achieves good environmental protection effect, convenient lamp-making process, and good low-temperature characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

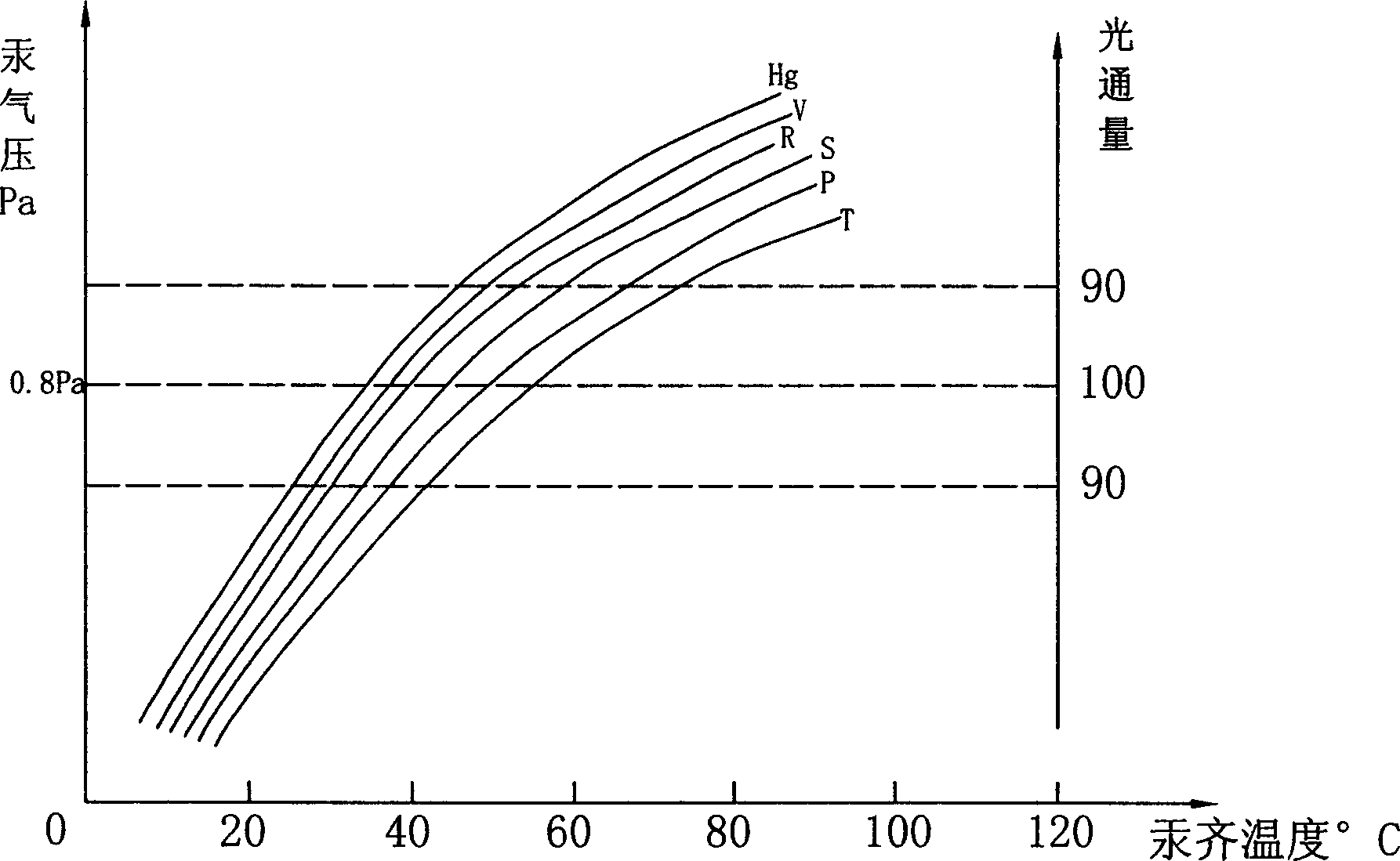

Embodiment 1

[0010] One of the preferred solutions for high mercury content solid mercury: the mass content of each component is Hg 60%, Sn 20%, Zn 15%, Ag 3%, Ga 2%, and the solid mercury can be obtained by conventional amalgam manufacturing methods , can be applied to the manufacture of fluorescent lamps, electrodeless lamps, ultraviolet germicidal lamps and advertising neon lights. The corresponding characteristic curve is V. When the temperature is -10°C, the lamp can also take off normally, and the instantaneous luminous flux can reach more than 95% of liquid mercury; The solid mercury is used in energy-saving lamps of 9-13 watts, and only 5 mg of mercury can be used to ensure a life of 8,000 hours. The traditional mercury-containing 30% ZnHg amalgam needs 10 mg of mercury, and the initial brightness of the lamp is low. , due to the heavy weight of the mercury ball particles, it is easy to scratch the fluorescent coating inside the lamp tube during transportation.

Embodiment 2

[0012] The second optimal solution for mercury solidification with high mercury content: the mass content of each component is Hg 60%, Sn 20%, Zn 15%, Ag 3%, In 2%, which can be applied to advertising neon lights with T3 and T4 diameters. For a 1.5-2m long lamp tube, only 10mg of the solid mercury needs to be injected to achieve qualified instantaneous brightness and stable brightness. There is no mercury spot on the lamp tube, and the corresponding characteristic curve of the lamp tube is V.

Embodiment 3

[0014] The third preferred option for mercury solidification with high mercury content: the mass content of each component is Hg 60%, Sn 20%, Zn 15%, Ag 3%, Ga 1%, In 1%, which can be applied to T2 and T3 pipe diameters The cold cathode fluorescent lamp can precisely control the amount of mercury, which is safe to manufacture and use, and can eliminate mercury spots on the wall of the lamp tube. The corresponding characteristic curve of the lamp tube is V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com