Processing method for improving washability of lyocell standard fiber fabric

A processing method and standard technology, applied in the direction of fiber processing, plant fiber, dry cleaning fiber products, etc., can solve the problem that cannot solve the washing resistance of lyocell standard fiber fabrics, the proportion of lyocell fibers is not high, and the fabric surface can not be solved. Problems such as poor finish, to achieve good style and practical performance, improve the problem of wet hardening, and improve the effect of washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

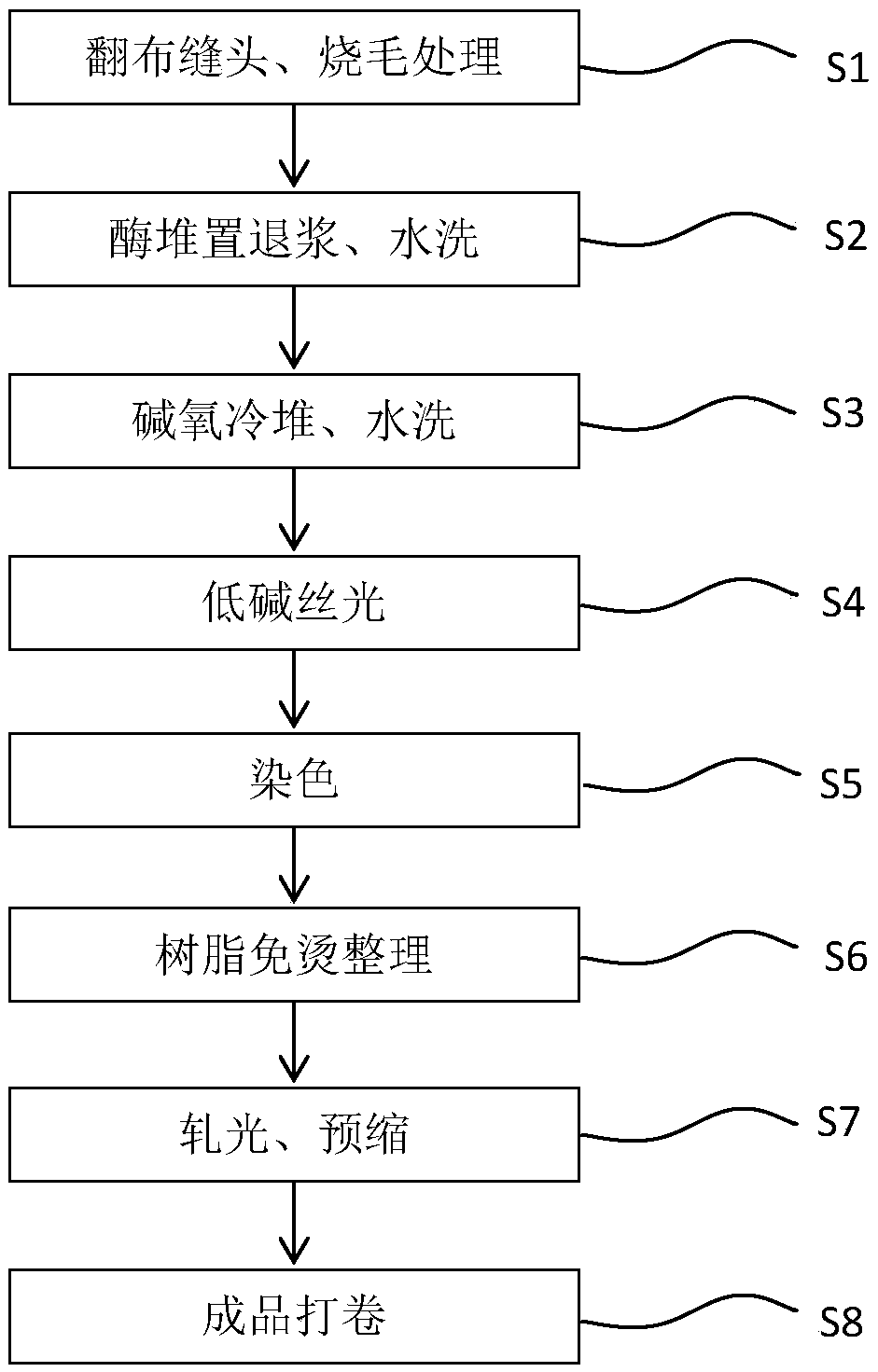

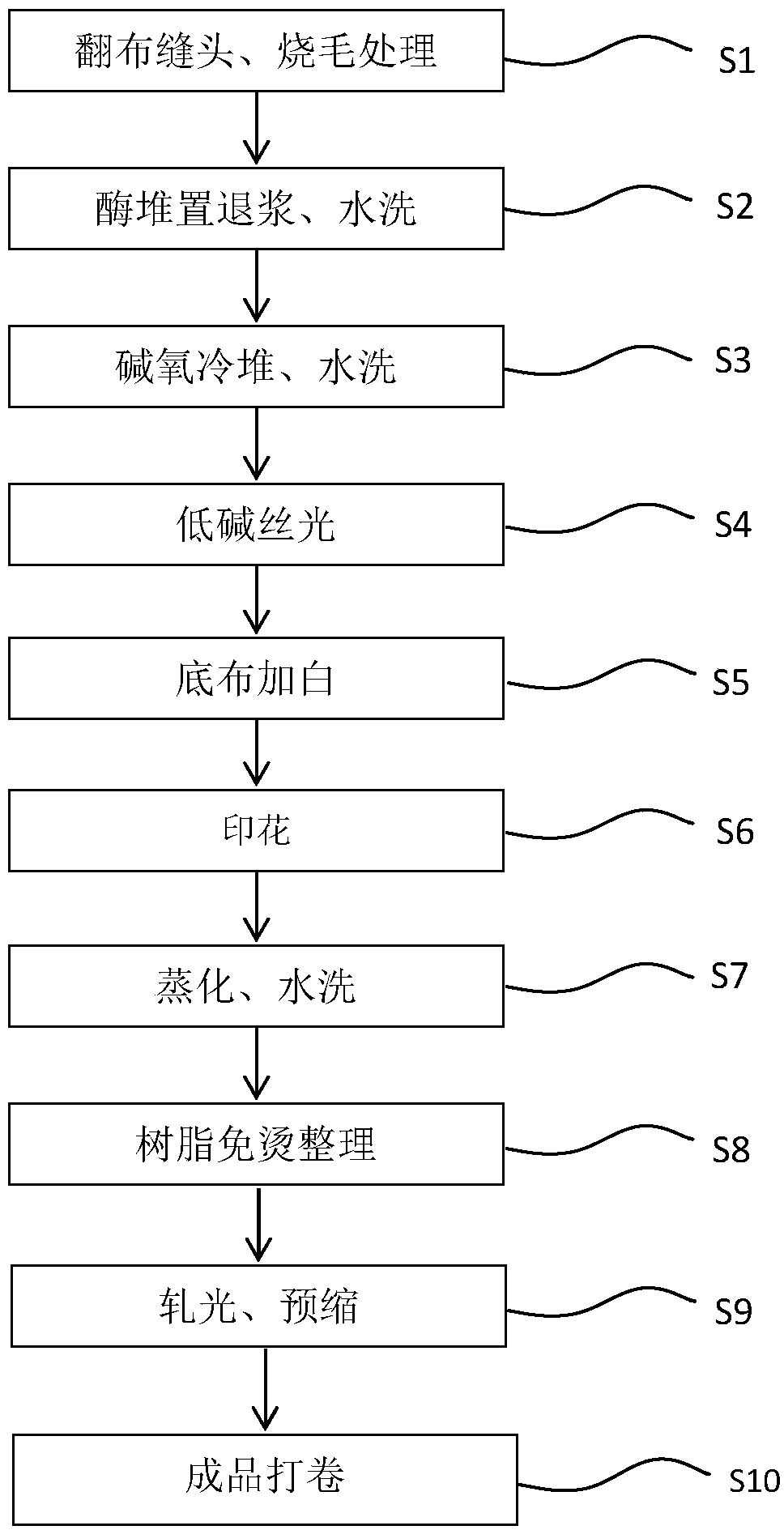

[0035] as attached figure 1 As shown, a processing method for improving the washing resistance of a lyocell standard fiber fabric, the processing process includes the following steps:

[0036] S1. Turning over the seam and singeing treatment, the fabric is turned over and seamed first; the gas singeing machine is used for the singeing treatment, the speed is 80m / min, the fabric is singed twice on the warp side and twice on the weft side , the flame temperature of each burner is 800°C, to ensure that the cloth surface is free of velvet and has a good finish;

[0037] S2. Enzyme stacking, desizing and washing. After the fabric is singed with an open flame, the temperature of the fabric surface is relatively high. After passing through the trough containing the first working fluid and the rolling car, the residual fire on the fabric surface is extinguished, and the first working fluid is rolled into it. In the cloth, the composition of the first working liquid: wide temperature ...

Embodiment 2

[0046] as attached figure 1 As shown, a processing method for improving the washing resistance of a lyocell standard fiber fabric, the processing process includes the following steps:

[0047] S1. Turning over the seam and singeing treatment, the fabric is turned over and seamed first; the gas singeing machine is used for the singeing treatment, the speed is 90-100m / min, the fabric is singed twice on the warp side, and the weft side is singed Twice, the flame temperature of each crater is 1000-1200 ℃, to ensure that the cloth surface is free of lint and has a good finish;

[0048] S2. Enzyme stacking, desizing and washing. After the fabric is singed with an open flame, the temperature of the fabric surface is relatively high. After passing through the trough containing the first working fluid and the rolling car, the residual fire on the fabric surface is extinguished, and the first working fluid is rolled into it. In the cloth, the composition of the first working liquid: wi...

Embodiment 3

[0056] as attached figure 1 As shown, a processing method for improving the washing resistance of a lyocell standard fiber fabric, the processing process includes the following steps:

[0057] S1. Turning over the seam and singeing treatment, the fabric is turned over and seamed first; the gas singeing machine is used for the singeing treatment, the speed is 120m / min, the fabric is singed twice on the warp side and twice on the weft side , the flame temperature of each burner is 1300°C, ensuring that the cloth surface is free of lint and has a good finish;

[0058] S2. Enzyme stacking, desizing and washing. After the fabric is singed with an open flame, the temperature of the fabric surface is relatively high. After passing through the trough containing the first working fluid and the rolling car, the residual fire on the fabric surface is extinguished, and the first working fluid is rolled into it. In the cloth, the composition of the first working solution: wide temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com