Centrifugal Acceleration Disc Structure of Pusher Centrifuge

A centrifugal acceleration and centrifuge technology, applied in the field of centrifuges, can solve the problems of small diameter design, small material impact, poor feeding, etc., and achieve the effects of reducing scratches, reducing impact force, and reducing filtration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

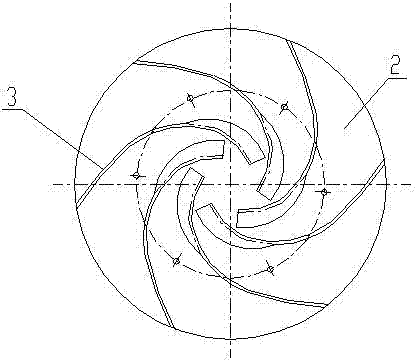

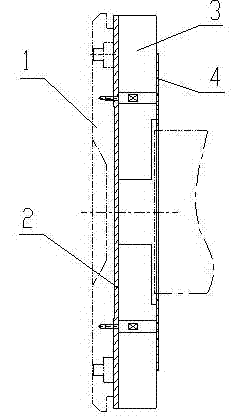

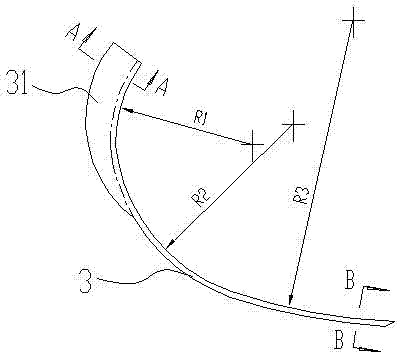

[0025] see figure 2 , the present embodiment is a centrifugal acceleration plate structure of a pusher centrifuge, two large circular flat plates 2 and a small circular flat plate 4 parallel to each other are set, wherein the large circular flat plate 2 is fixed on the pusher plate 1 of the pusher centrifuge On, the small circular flat plate 4 is connected with the large circular flat plate 2 as a whole with a screw rod. Set 6 blades 3 between the large circular flat plate 2 and the small circular flat plate 4, and the 6 blades 3 are distributed into a uniform radial shape, such as figure 1 As shown, the tail ends of the six blades 3 are located on the same circumference, and the curve of the blades 3 is designed as a turbine centrifugal line, which is composed of three arcs, such as image 3 R1, R2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com