SP-grade gasoline engine oil and preparation method thereof

A gasoline engine oil, high-grade technology, applied in the field of lubricating oil, can solve the problems that the comprehensive performance needs to be further improved, and achieve the effects of protecting the engine timing chain system, enhancing wear protection, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An SP grade gasoline engine oil in this embodiment is composed of the following raw materials in mass percentage: Lubrizol PV1410: 7.9% for gasoline engine oil compounding agent; Infineum SV260: 8% for viscosity index improver; RIPP for pour point depressant -T866: 0.3%; base oil A uses PAO 164: 17.6%; base oil B uses PAO 166: 66.2%.

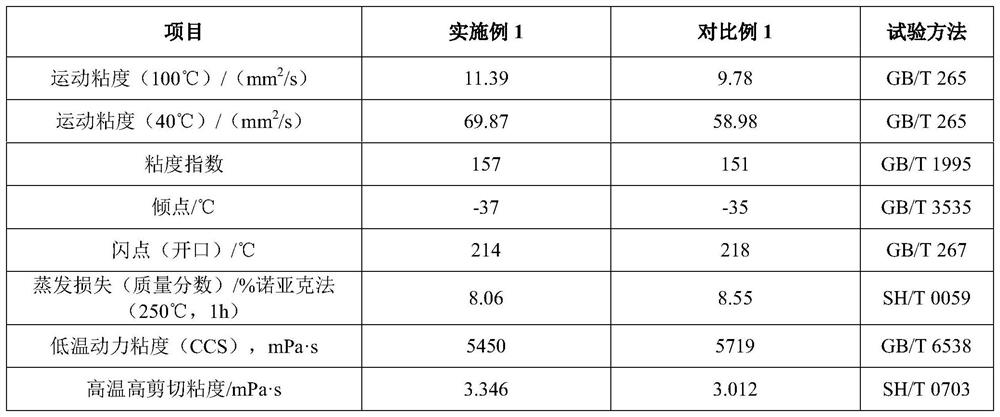

[0037] The preparation method is as follows: add the above-mentioned components in the order of the order of the ingredients into the blending kettle, raise the temperature to 60°C, heat and stir for 1.5 hours, until the components are mixed evenly and the appearance is clear, filter while it is hot, and cool to room temperature. Promptly get described SP grade gasoline engine oil, the performance index of gained product is detected, and detection result is as follows: figure 1 shown.

Embodiment 2

[0039] A kind of SP grade gasoline engine oil of the present embodiment is made up of the raw material of following mass percentage: Gasoline engine oil compounding agent adopts Lubrizol PV1410: 12%; Viscosity index improver adopts Chevron 8900E: 7.5%; Kex 1-248: 0.5%; base oil A selection of 4CST: 30%; base oil B selection of PAO 166: 50%.

[0040] The preparation method is as follows: add the above-mentioned components in the order of the order of the ingredients into the blending kettle, raise the temperature to 55°C, heat and stir for 1.5 hours, until the components are mixed evenly and the appearance is clear, filter while it is hot, and cool to room temperature. That is, the SP grade gasoline engine oil is obtained, and the performance index of the product obtained is detected, and the detection results are basically as in Example 1.

Embodiment 3

[0042] An SP grade gasoline engine oil of this embodiment is composed of the following raw materials in mass percentage: gasoline engine oil compounding agent adopts Lubrizol PV1510: 5%; viscosity index improver adopts Infineum SV260: 4.9%; pour point depressant adopts Roman X 1-300: 0.1%; base oil A uses X420: 10%; base oil B uses 6CST: 80%.

[0043] Its preparation method is as follows: add the above-mentioned components into the blending kettle in sequence according to the order of the components, raise the temperature to 45°C, heat and stir for 1 hour, until the components are mixed evenly and the appearance is clear, filter while it is hot, and cool to room temperature. Obtain described SP grade gasoline engine oil, the performance index of gained product is detected, and detection result is basically as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com