Method for improving engine fuel efficiency

a technology of engine fuel efficiency and friction reduction, applied in the petroleum industry, additives, lubricant compositions, etc., can solve the problems of increasing wear, reaching the limits of current equipment capabilities and specifications, etc., and achieve the effect of improving friction reduction and fuel efficiency, maintaining or improving wear protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

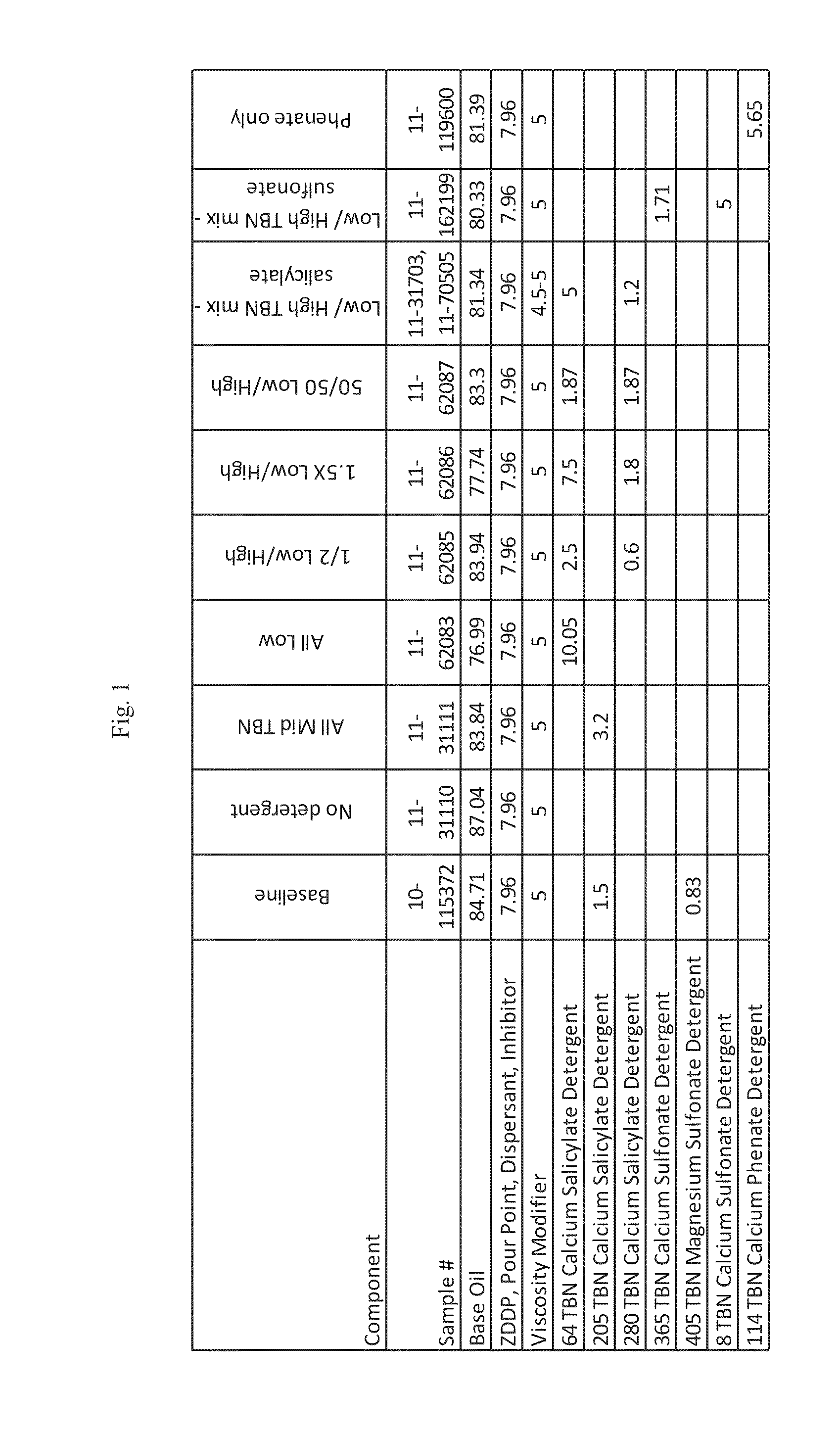

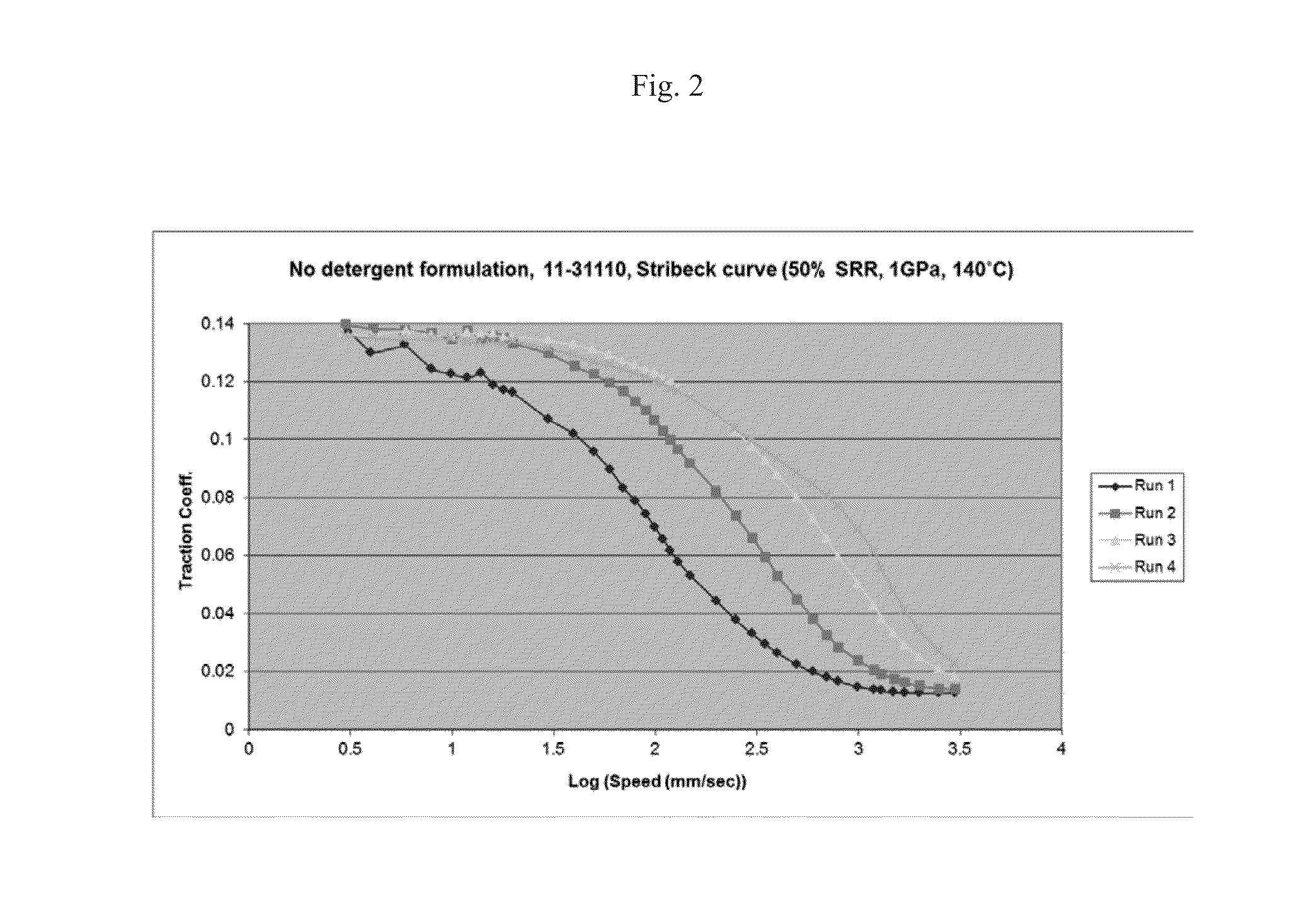

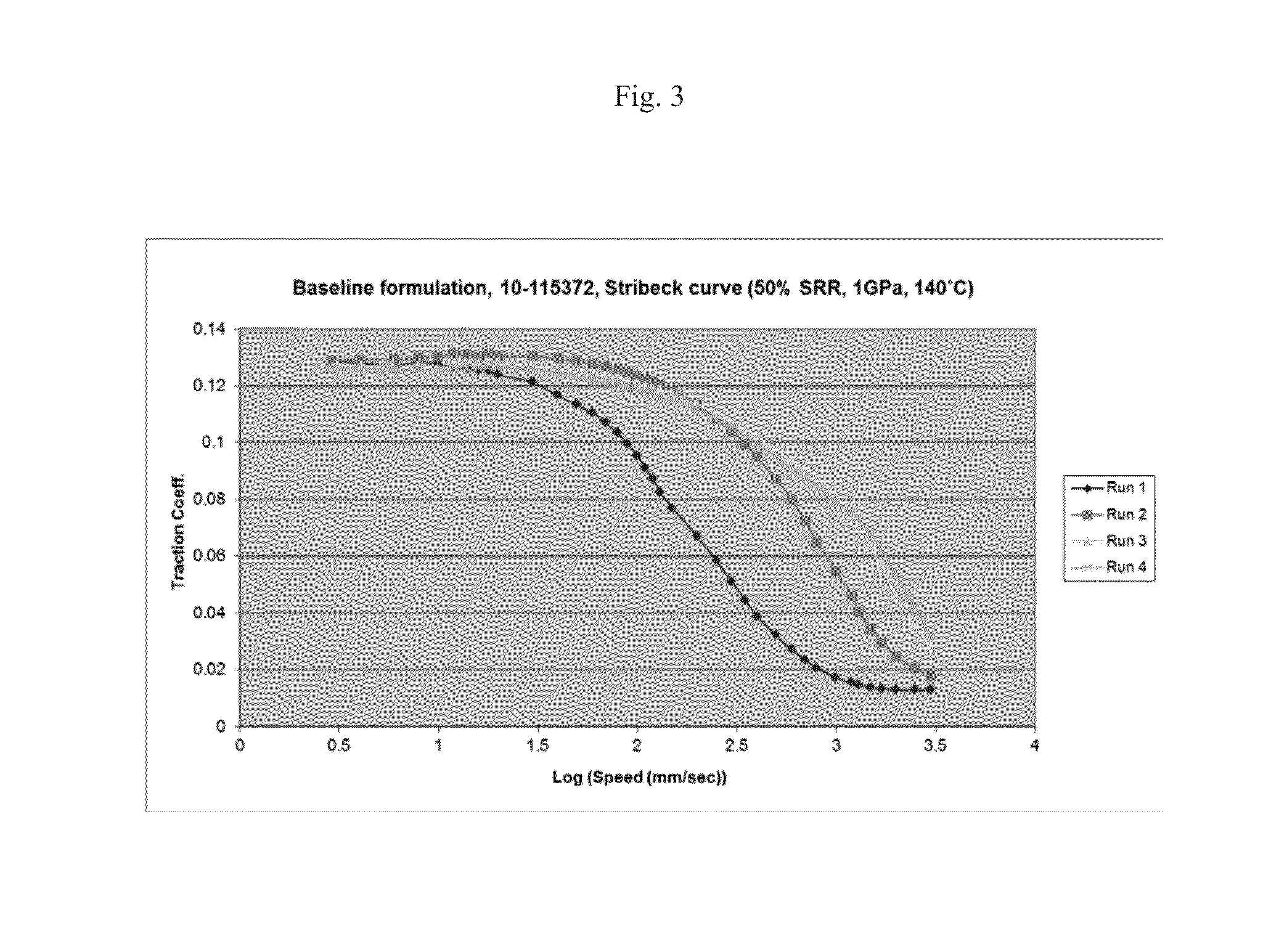

[0121]A fully formulated 0W-20 synthetic oil containing calcium salicylate and magnesium sulfonate detergents was used as a baseline oil, against which all other oils were compared. Friction measurements by mini-traction machine (MTM) in Stribeck mode at 140° C., 1 GPa load, and 50% slide to roll ratio were carried out on all oils. High frequency reciprocating rig (HFRR) measurements were carried out on all oils using a temperature ramp mode from room temperature to 195° C. These two types of measurements provided an indication of the frictional performance of lubricants. Engine testing in the Sequence IIIG (D7320), VID (D7589), VW TDi2, and OM646 LA were carried out to ascertain wear, deposit formation and fuel economy performance of select oils.

[0122]Lubricant oils were formulated containing no magnesium sulfonate, and varying amounts of calcium salicylate or calcium sulfonate. Calculated total base number was held constant for FIGS. 3-9, but the total soap to calcium ratio was va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stribeck friction coefficients | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com