Method for centrifugal production of yellow wine employing horizontal screw-disk combination

The technology of a decanter centrifuge and a separation method, which is applied in the field of brewing, can solve the problems of hindering the development of yellow rice wine production and quality, and the loss of manufacturers, and achieve the effects of improving the brightness of yellow rice wine, small footprint and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Yellow rice wine is produced according to the following steps:

[0031] 1. Rice soaking: remove impurities from the glutinous rice, wash it, put it into a rice soaking tank, add water to soak the rice for 24 hours;

[0032] 2. Steam rice: After soaking the rice, take out the rice and rinse it, drain and steam the rice until there is no white heart inside the rice grains;

[0033] 3. Drain the rice: Rinse the steamed glutinous rice with water to lower the temperature of the glutinous rice;

[0034] 4. Blanking: drain the excess water from the glutinous rice after pouring rice, pump it into the fermentation tank, add water according to the ratio of glutinous rice: water = 1: 1.25 (Kg / L), and then add raw materials 16% (M / M) wheat koji, inoculated with 3% (M / M) distiller's mother, and mixed various materials;

[0035] 5. Fermentation: ferment for 5 days at 28°C in the front fermenter, and ferment for 25 days at 20°C in the rear fermenter;

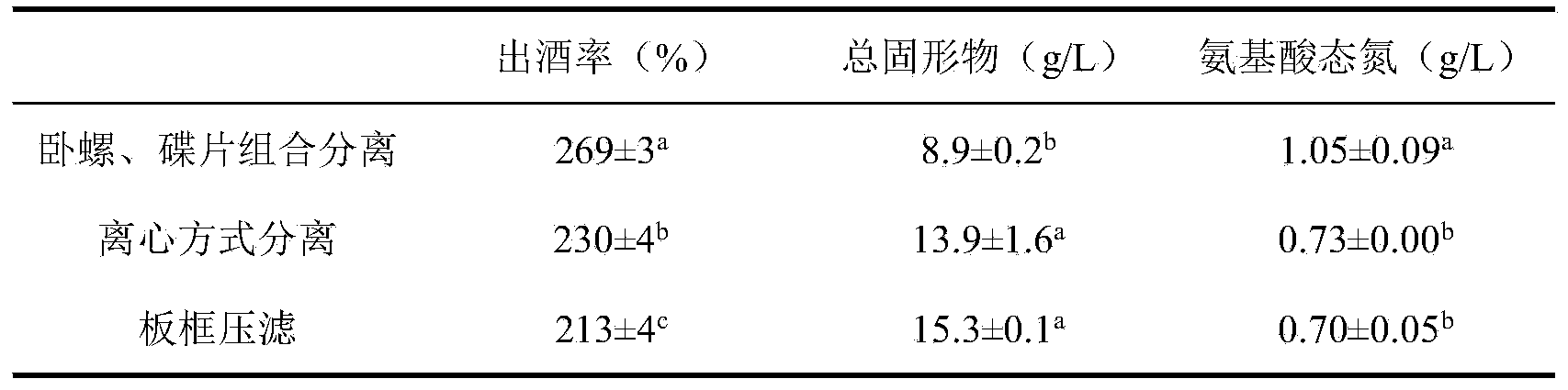

[0036] 6. Pressing wine: Afte...

Embodiment 2

[0039] Yellow rice wine is produced according to the following steps:

[0040] 1. Rice soaking: Remove impurities from the glutinous rice, wash it, put it into a rice soaking tank, and soak it in water for 3 days;

[0041] 2. Steam rice: Take out the rice, rinse it with clean water, drain it, and then steam the rice until there is no white heart inside the rice grains;

[0042] 3. Drain the rice: Rinse the steamed glutinous rice with water to lower the temperature of the glutinous rice;

[0043] 4. Blanking: Drain the excess water from the glutinous rice after pouring rice, put the steamed glutinous rice into the fermentation tank with a pump, add water according to the ratio of glutinous rice: water = 1: 1.35 (Kg / L), and then add raw material quality 11 % (M / M) wheat koji, finally inoculated with 4% (M / M) wine mother, and mixed;

[0044] 5. Fermentation: the rice wine is fermented in the front fermenter at 28°C for 5 days, and put into the rear fermenter at 18°C for 15 days...

Embodiment 3

[0050] Our laboratory previously published a related patent - "A Method for Producing Yellow Rice Wine by Feed Addition and Centrifugation", and the application publication number is CN103789180A. This example is implemented according to this patent, and the specific scheme is as follows:

[0051] 1. Rice soaking: remove impurities from the glutinous rice, wash it, put it into a rice soaking tank, add water to soak the rice for 24 hours;

[0052] 2. Steam rice: After soaking the rice, take out the rice and rinse it, drain and steam the rice until there is no white heart inside the rice grains;

[0053] 3. Drain the rice: Rinse the steamed glutinous rice with water to lower the temperature of the glutinous rice;

[0054] 4. Blanking: drain the excess water from the glutinous rice after pouring rice, pump it into the fermentation tank, add water according to the ratio of glutinous rice: water = 1: 1.25 (Kg / L), and then add raw materials 16% (M / M) wheat koji, inoculated with 3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com