Energy-saving emission-reducing lubricant composition

A lubricating oil composition, a technology for energy saving and emission reduction, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as lack of comprehensive energy saving effect, decrease in effective molybdenum content, increase in fuel consumption, etc., and achieve improved fuel economy maintenance. Ability, high synergistic effect of friction reduction and synergy, and the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The mixed base oil and the mass percentage of 60% polyalphaolefin synthetic base oil and 20% ester oil and 20% additives are weighed, and the additives include a viscosity index improver, a pour point depressant, an extreme pressure Agent, cleaning agent, anti-oxidant anti-corrosion anti-rust agent, anti-friction and anti-wear synergist, antifoaming agent, according to the lubricating oil composition of energy saving and emission reduction described in claim 1, wherein poly-alpha olefin or polymethacrylic acid Methyl ester, whose content is 5% by weight of the composition, calcium sulfonate or calcium salicylate, whose content is 3% by weight of the composition, boric acid fatty ester amine salt, whose content is 3% by weight of the composition 0.5% (by boron weight). Benzotriazole dodecylamine salt, its content is 5% that accounts for composition mass percent.

Embodiment 2

[0028] Preparation method Add the base oil into the blending kettle according to the metered quantity, start stirring, raise the temperature to 65-70 degrees Celsius, add the quantities of each component to the base oil in the following order, first add the pour point depressant, and the second add Viscosity index improver, followed by adding extreme pressure agent, detergent, anti-oxidation, anti-corrosion and anti-rust agent, anti-friction and anti-wear synergist, anti-foaming agent. After adding all the components, keep the original temperature and continue to stir for 30 minutes. After all the components are mixed evenly, cool down to room temperature to obtain a homogeneous, light brown, clear and transparent lubricating oil.

Embodiment 3

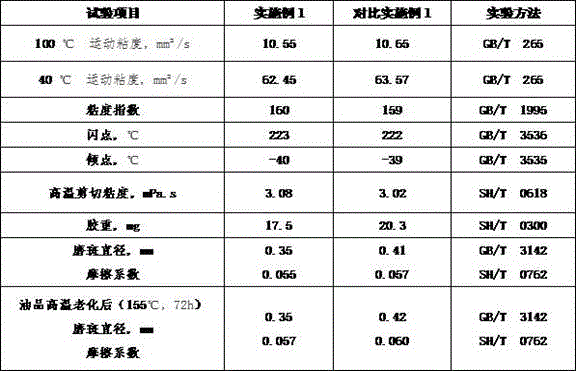

[0029] Embodiment 3 Comparison experiment of product main performance indicators

[0030] Table 1 Comparison table of main performance indicators of products

[0031]

[0032] From the test results of rubber weight, wear spot diameter and friction coefficient in Table 1 above, it can be seen that the product of the present invention has good high-temperature detergency and lubrication and anti-friction properties, and the oil product still has good anti-wear properties after high-temperature aging test. Anti-friction, indicating that the oil has good anti-friction durability, which can make the oil have a good ability to maintain fuel economy. Low coefficient of friction, high synergistic effect of friction reduction and synergistic effect, with significant energy saving and emission reduction effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com