High-concentrated detergent containing comb polyether composition

A composition and detergent technology, applied in the field of daily chemicals, can solve the problems of thinning, affecting the sensory feeling of consumers, etc., and achieve the effects of low pour point, elimination of gel phenomenon, and less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve part of the sodium hydroxide in water, and then use the conventional detergent preparation method and feeding sequence in the prior art to prepare concentrated detergent according to the formula amount, and finally adjust the pH of the system to the target pH with an appropriate amount of sodium hydroxide solution .

[0031] The specific dosage of each component is as follows:

[0032] Alkylbenzenesulfonic acid: 15g;

[0033] Fatty acid methyl ester ethoxy condensate (FMEE): 10g;

[0034] Comb polyether composition: 21g;

[0036] Propylene glycol: 9g;

[0037] Sodium hydroxide: appropriate amount;

[0038] Pigment: appropriate amount;

[0039] Preservatives: 0.2g;

[0040] Flavor: 0.4g;

[0041] Add water to 100g.

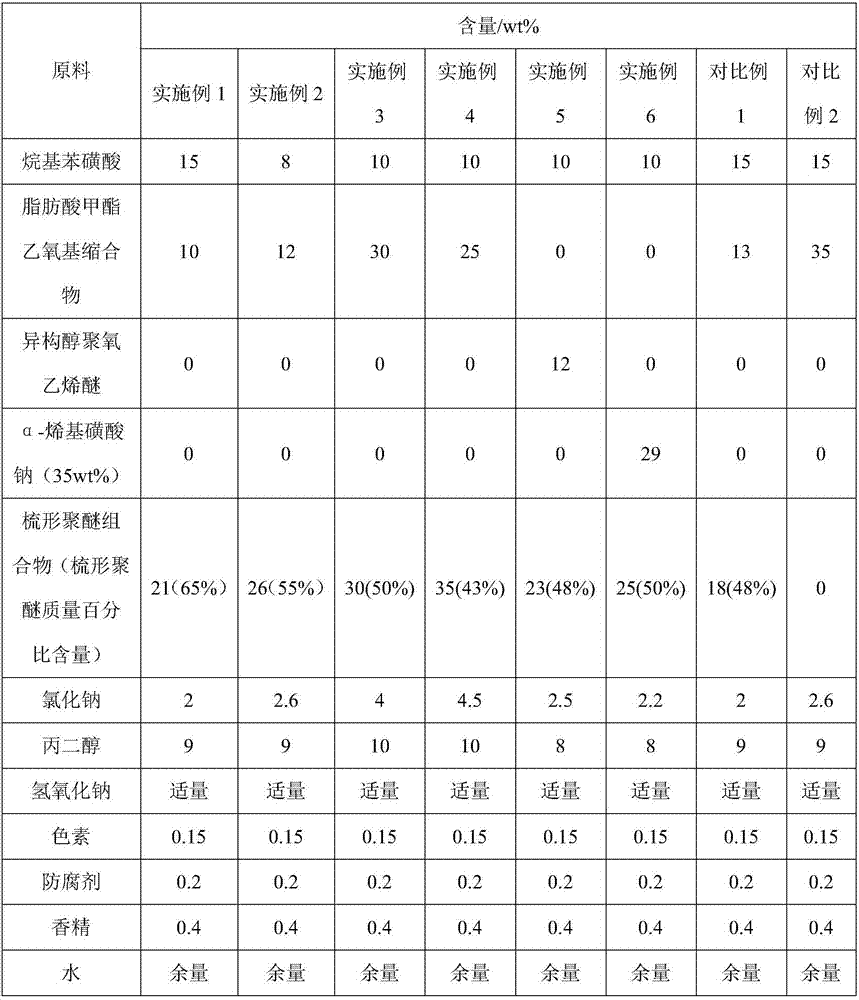

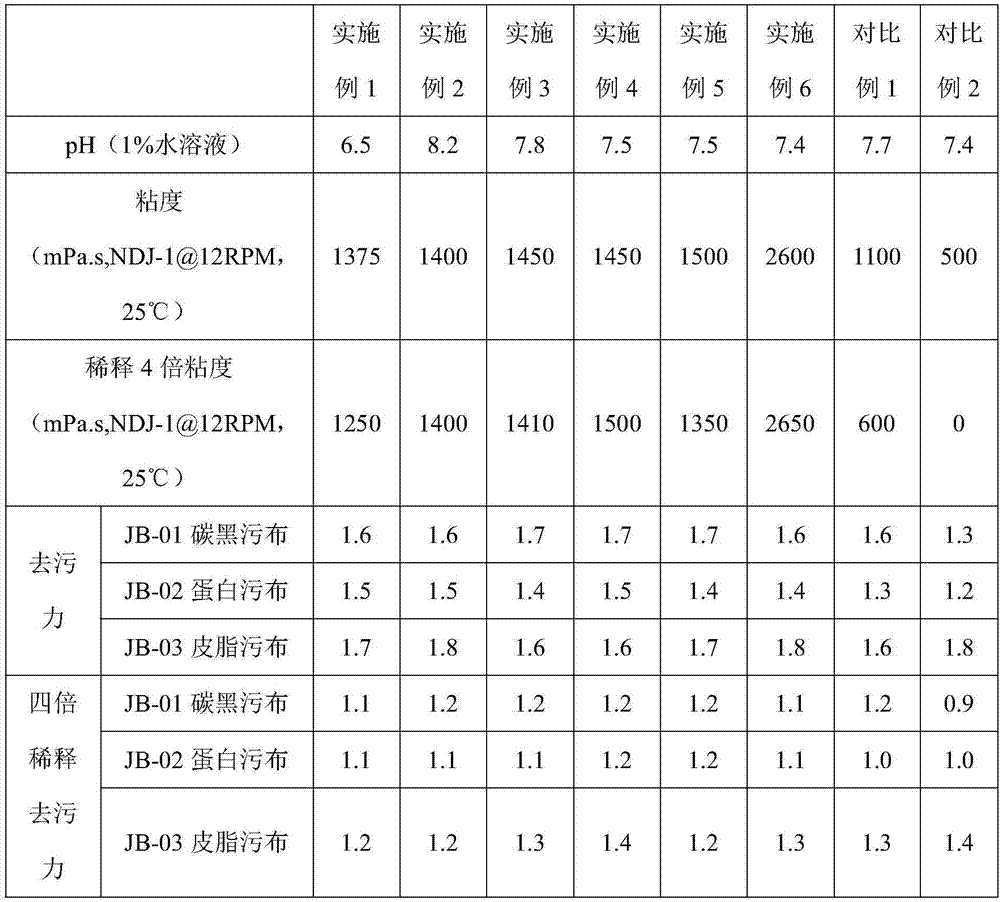

[0042] Embodiment 2-6 and comparative example 1 and 2 preparation method are with embodiment 1, and formula is as follows table 1:

[0043] Table 1: the formula table of embodiment 1-6 and comparative example 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com