A kind of polymer surfactant binary composite oil displacement agent

A surfactant, binary compound flooding technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large-scale application, high cost of surfactants and polymers, and achieve good cleaning. Oil efficiency, good viscosity retention, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another object of the present invention is to provide a kind of synthetic method of polymer surfactant binary composite oil displacement agent, and this synthetic method comprises the following steps:

[0047] Step 1: Using acrylamide AM, N-vinylpyrrolidone NVP, and sodium allyl sulfonate AS as reactive monomers, a polymer with temperature and salt resistance is synthesized by free radical polymerization under the trigger of a redox initiation system ;

[0048] In step 2, petroleum carboxylate and carboxybetaine are compounded in a certain proportion to form a surfactant system;

[0049] Step 3, the compounded surfactant and a certain concentration of the above-mentioned polymers are used to form a polymer surfactant binary composite oil displacement agent.

[0050] In the embodiment of the present invention, in step 1, using acrylamide AM, N-vinylpyrrolidone NVP, and sodium allyl sulfonate AS as reaction monomers, under the triggering of a redox initiation system, syn...

Embodiment 1

[0084] Embodiment 1: the preparation of polymer

[0085] Synthetic initiator water-soluble azobisisobutylamidine dihydrochloride (AIBA·2HCl):

[0086] Add anhydrous methanol and refined azobisisobutyronitrile into a four-neck flask, add a certain amount of sodium methoxide under stirring, stir for a certain period of time at 25°C, and react for 18 hours; then add a certain amount of NH 4 C1, continue to stir at this temperature for a certain period of time, react for 22 hours, stop the reaction and let it stand, filter the reaction solution, discard the precipitated NaCl, filter the filtrate under reduced pressure, remove the solvent methanol, and rinse the obtained solid with a small amount of cold methanol for 2-3 times, and then distilled under reduced pressure to obtain azobisisobutylamidine hydrochloride as a white solid.

[0087] Preparation of polymer

[0088] Weigh 16.79 grams of acrylamide (AM), 1.12 grams of N-vinylpyrrolidone (NVP), 0.09 grams of sodium allyl sulf...

Embodiment 2

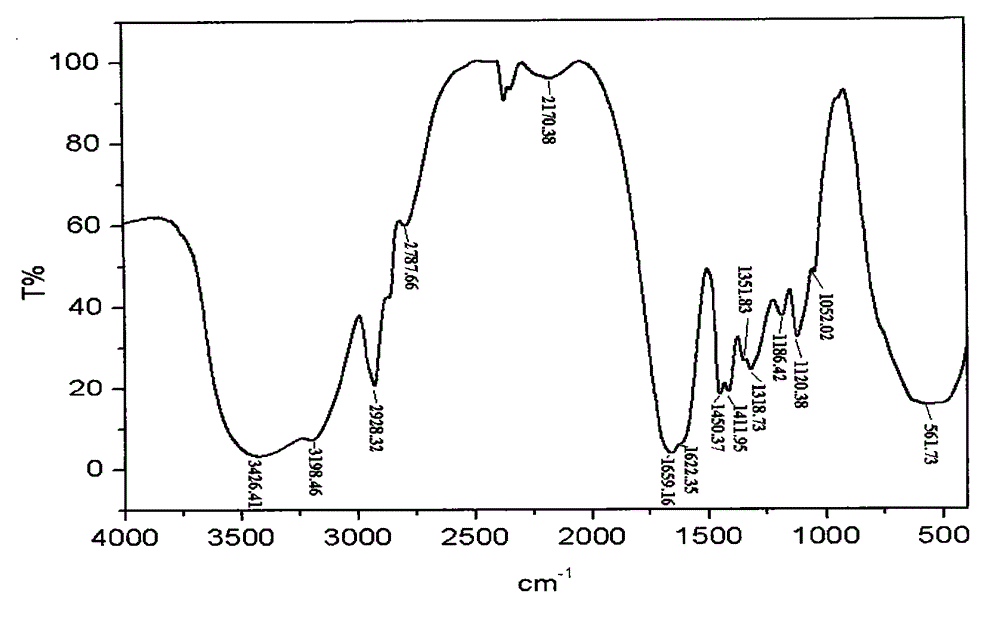

[0089] Example 2: Structural Characterization of Polymers

[0090] Take a certain amount of the dry AM / NVP / AS polymer prepared in Example 1 and mix it with spectroscopically pure potassium bromide and grind it, press the mixed and ground sample into thin slices and fix it on the sample holder, and use an infrared spectrometer to analyze it. Spectral identification was carried out, and the results of infrared spectrum analysis are shown in Table 1.

[0091] Table 1 AM / NVP / AS polymer functional group characteristic peaks

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com