Organic modified hydrophobic nano silica hollow ball and preparation method thereof

A hydrophobic nano and hollow sphere technology, applied in the field of nano materials, can solve the problems of limited application, poor dispersion, poor oil phase dispersion, etc., and achieve the effect of uniform cavity, good oil phase dispersion and high hydrophobic angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

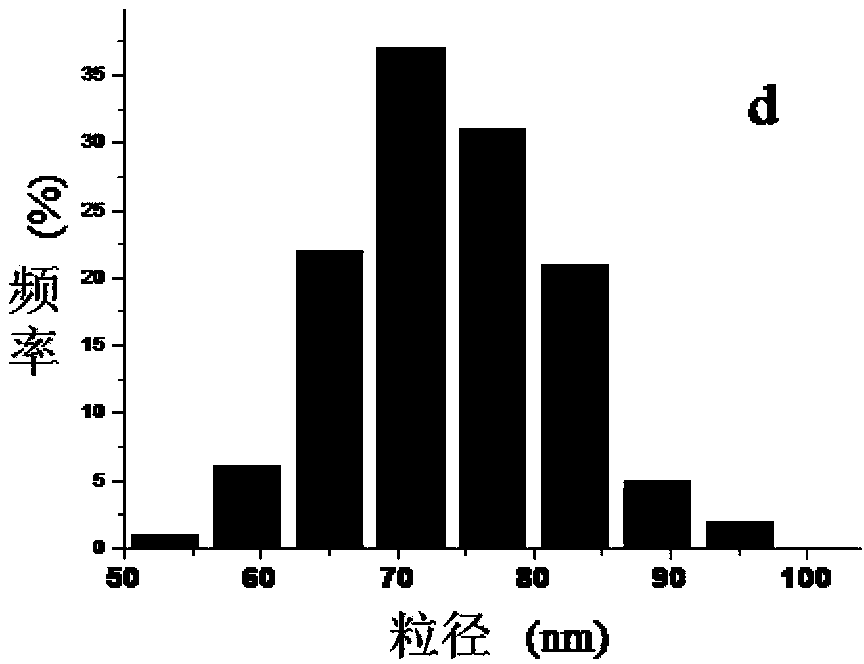

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of Material A (EtHS)

[0026] Take 15.5g Np-12, 25g toluene, 2g ammonia water with a mass concentration of 25%~28%, mix 5.5g water and 3g n-butanol to obtain solution A; mix 1g ethyl orthosilicate and 0.5g ethyltrimethoxysilane to obtain B: Add solution B to A under vigorous stirring, stir vigorously for 30 minutes, age for 24 hours, add 20 mL of ethanol, and centrifuge to obtain a white solid. Add 50 mL of ethanol to the solid, heat to 40°C and stir for 10 min, collect the solid by centrifugation, and repeat 6 times until the impurities are removed. Dry at 80°C for 12h. The resulting white solid was added to 80 mL of ethanol and ultrasonicated for 1 h. Add 10 mL of hydrochloric acid with a mass concentration of 4%, and stir for 12 h. Centrifuge to obtain a white solid, which is washed 3 times with 20 mL of ethanol each time. Dry at 80°C for 12h to obtain EtHS.

Embodiment 2

[0027] Example 2 Preparation of Material B-E

[0028] The preparation method of material B-E is the same as material A, the difference lies in the types of organosilane, small molecule alcohol and inorganic acid, the specific types are shown in Table 1, and the obtained materials are listed in Table 1

[0029] Table 1 Types of organosilanes, small molecule alcohols and inorganic acids used in the preparation of materials B-E

[0030]

Embodiment 3

[0031] Example 3 Preparation of material F (DoHS)

[0032] Mix 20g Np-7, 15g cyclohexane, 1g 25%~28% ammonia water, 7.5g water and 3g n-hexanol to obtain solution A; mix 2g tetraethyl orthosilicate and 0.4g dodecyltrimethoxysilane B: Add solution B to A under vigorous stirring, stir vigorously for 30 minutes, age for 8 hours, add 20 mL of ethanol, and centrifuge to obtain a white solid. Add 50 mL of ethanol to the solid, heat to 50°C, stir for 10 min, centrifuge, and repeat 6 times until impurities are removed. Dry at 80°C for 12h. The resulting white solid was added to 80 mL of methanol and ultrasonicated for 1 h. Add 10mL of 4% hydrofluoric acid and stir for 2h. Centrifuge to obtain a white solid, which is washed 3 times with 20 mL of ethanol each time. Dry at 80°C for 12 hours to obtain DoHS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com