Clean compound ester type high temperature chain oil and preparation method

A technology of high-temperature chains and complex esters, applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as low application temperature, large evaporation loss, and poor lubricity, and achieve reduced use consumption, less coking, and high-temperature thermal stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 2

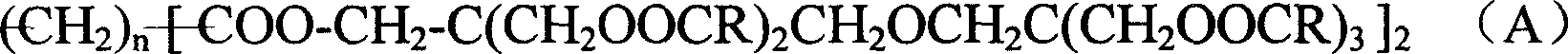

[0023] Dipentaerythritol complex ester 65.3 73.9

[0024] Pyromellitic acid ester 30.0 20.0

[0025] Amine antioxidant 2.5 3.0

[0026] Triphenylphosphorothioate 2.0 3.0

[0027] Bisbenzotriazole 0.2 0.1

[0028] In Example 1: the kinematic viscosity of dipentaerythritol complex ester at 40°C is 650-800mm 2 / s; kinematic viscosity of pyromellitic acid ester at 40°C is 80-95mm 2 / s; the antioxidant is a mixture of alkylated diphenylamine and alkylated N-phenyl-α-naphthylamine.

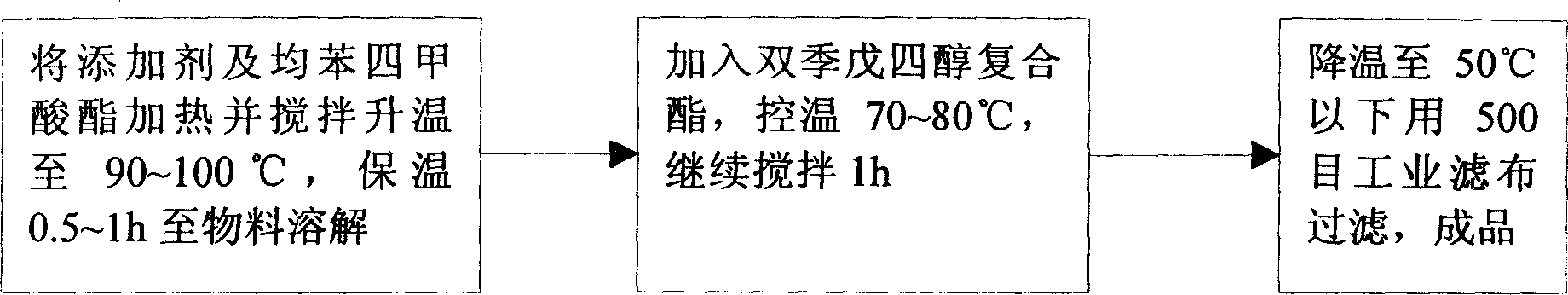

[0029] The deployment process is as shown in the preparation process flow chart of the present invention:

[0030] (1) Heat and stir the amine antioxidant, triphenyl thiophosphate, bisbenzotriazole and pyromellitic acid ester to 90-100°C, and keep warm for 0.5-1 hour to completely dissolve the solid material;

[0031] (2) Add dipentaerythritol complex ester in turn, control the temperature at 70-80°C, and continue stirring for 1 hour;

[0032] (3) Cool down to below 50°C and filter with 500 mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com