Dislocation identification method of silicon carbide crystal

An identification method and technology of silicon carbide, which is applied in the preparation of test samples, optical test flaws/defects, etc., can solve the problems of inability to realize identification at the same time, long corrosion time, etc., to achieve accurate identification, short corrosion time, easy characterization and The effect of statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

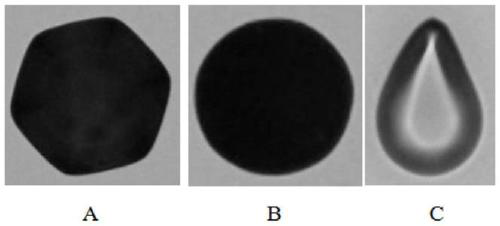

[0051] Example 1: Dislocation identification method for high-purity silicon carbide

[0052] This embodiment describes a dislocation identification method for high-purity silicon carbide, the method comprising the following steps:

[0053] (1) Pretreatment: The high-purity silicon carbide is firstly ground and polished according to the normal process to make it have a flat and smooth surface. Then use ultrapure water to clean the crystal surface particles, dilute sulfuric acid to clean the crystal surface grease, and use hydrofluoric acid (mass concentration is 8%) to pre-corrode the crystal surface. The temperature of the pre-corrosion is 20 ° C. It is also possible to eliminate scratches on the crystal surface; finally use hydrogen peroxide and sodium bicarbonate to neutralize and clean the pretreatment solution. Then use ultra-pure water to wash and dry the wafer several times to complete the pretreatment process. The purpose of pretreatment: one is to clean the surface o...

Embodiment 2

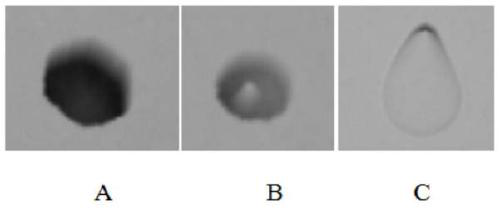

[0057] Example 2: Dislocation identification method for high-purity silicon carbide

[0058] This embodiment describes a dislocation identification method for high-purity silicon carbide, the method comprising the following steps:

[0059] (1) Pretreatment: The high-purity silicon carbide is firstly ground and polished according to the normal process to make it have a flat and smooth surface. Then use ultra-pure water to clean the crystal surface particles, dilute hydrochloric acid to clean the crystal surface grease, and use nitric acid (mass concentration is 5%) to carry out pre-corrosion on the crystal surface. Surface scratches are eliminated and removed; finally, hydrogen peroxide and sodium bicarbonate are used to neutralize and clean the pretreatment solution. Then use ultra-pure water to wash and dry the wafer several times to complete the pretreatment process.

[0060] (2) Dislocation corrosion process: KOH solid particles are placed in a nickel crucible and melted ...

Embodiment 3

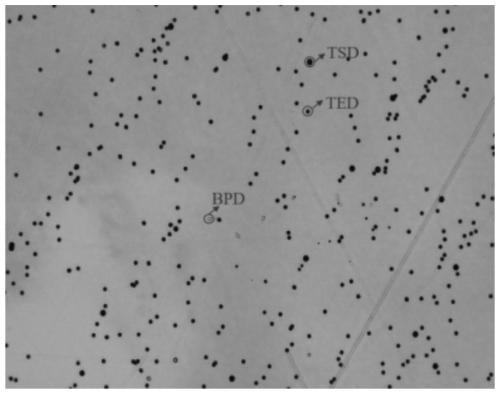

[0062] Example 3: Dislocation identification method for high-purity silicon carbide

[0063] This embodiment describes a dislocation identification method for high-purity silicon carbide, the method comprising the following steps:

[0064] (1) Pretreatment: The high-purity silicon carbide is firstly ground and polished according to the normal process to make it have a flat and smooth surface. Then use ultrapure water to clean the crystal surface particles, dilute sulfuric acid to clean the crystal surface grease, and use a mixture of hydrofluoric acid and nitric acid with a molar ratio of 6:1 to pre-corrode the crystal surface. The pre-corrosion temperature is 15 ℃, the mass concentration of the mixed solution of hydrofluoric acid and nitric acid is 10%, the mixed solution of hydrofluoric acid and nitric acid can also eliminate the scratches on the crystal surface; Neutralize and clean. Then use ultra-pure water to wash and dry the wafer several times to complete the pretrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com