Metallographical corrosive for medium entropy high-temperature alloy and corrosion method

A high-temperature alloy and corrosive agent technology, which is applied in the preparation of test samples, instruments, and analytical materials, etc., can solve the problems of metallographic inspection difficulties, no corrosive agents and corrosion methods, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

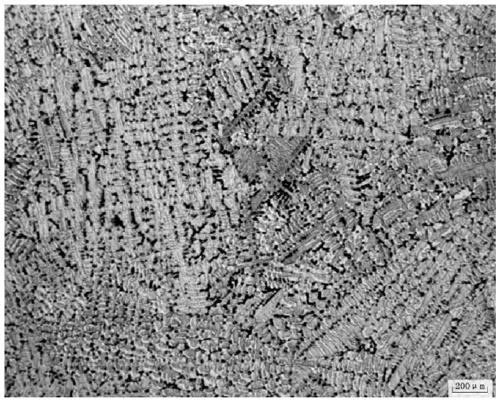

[0019] For conventional metallographic sampling, use an 80-mesh grinding wheel to smooth the sample, and then use 400#, 500#, and 900# sandpaper to smooth the surface of the sample. Each sandpaper grinding should completely cover the grinding marks of the previous sandpaper, and the polishing machine will polish it. . Sample corrosion: Mix 5g of copper sulfate, 15ml of hydrochloric acid, 10ml of water, 2g of ferric chloride, and 2ml of nitric acid to make a corrosive agent, put the sample into the corrosive agent, the stainless steel plate is the cathode, the sample is the anode, and the electrolysis voltage is 1.5V , the current is 0.1A, and the electrolytic corrosion time is 60s. After the sample is taken out, it is cleaned with alcohol and dried. The morphology of the sample tissue was observed and evaluated under an optical microscope.

Embodiment 2

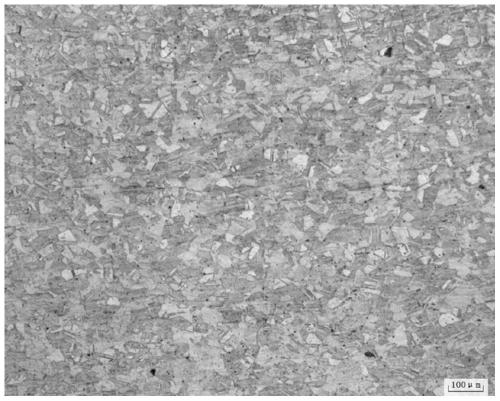

[0021] For conventional metallographic sampling, use an 80-mesh grinding wheel to smooth the sample, and then use 400#, 500#, and 900# sandpaper to smooth the surface of the sample. Each sandpaper should completely cover and remove the grinding marks of the previous sandpaper. polishing. Sample corrosion: Mix 10g of copper sulfate, 30ml of hydrochloric acid, 25ml of water, 3g of ferric chloride, and 4ml of nitric acid to make a corrosion agent. The stainless steel plate is used as the cathode, and the sample is used as the anode. The electrolytic voltage is 5V, the current is 0.3A, and the electrolytic corrosion time After 20 seconds, the sample was cleaned with alcohol and dried. The morphology of the sample tissue was observed and evaluated under an optical microscope.

Embodiment 3

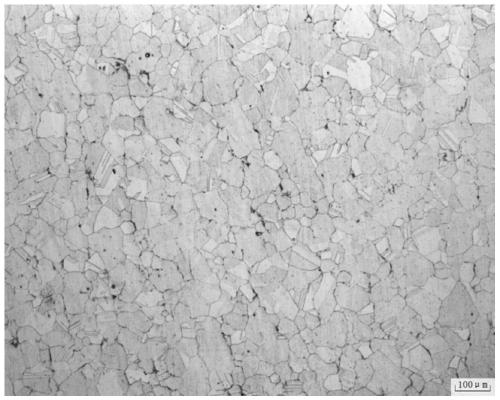

[0023] For conventional metallographic sampling, use an 80-mesh grinding wheel to smooth the sample, and then use 400#, 500#, and 900# sandpaper to smooth the surface of the sample. Each sandpaper should completely cover and remove the grinding marks of the previous sandpaper. polishing. Sample corrosion: Mix 7g of copper sulfate, 20ml of hydrochloric acid, 20ml of water, 2g of ferric chloride, and 2ml of nitric acid to make a corrosion agent. The stainless steel plate is the cathode, and the sample is the anode. The electrolytic voltage is 3V, the current is 0.2A, and the electrolytic corrosion time After 30s, the sample was taken out and cleaned with alcohol and dried. The morphology of the sample tissue was observed and evaluated under an optical microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com