Low-pressure corrosion device and method for quartz microwell plate

A technology of corrosion device and micro-orifice plate, which is applied in the field of processing technology, can solve the problems of uneven single micro-hole and different corrosion rates, and achieve the effects of remarkable corrosion effect, uniform corrosion rate and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A kind of quartz microporous plate low-pressure etching method provided by the invention comprises the following steps:

[0018] 1) Configure the solution required for corrosion.

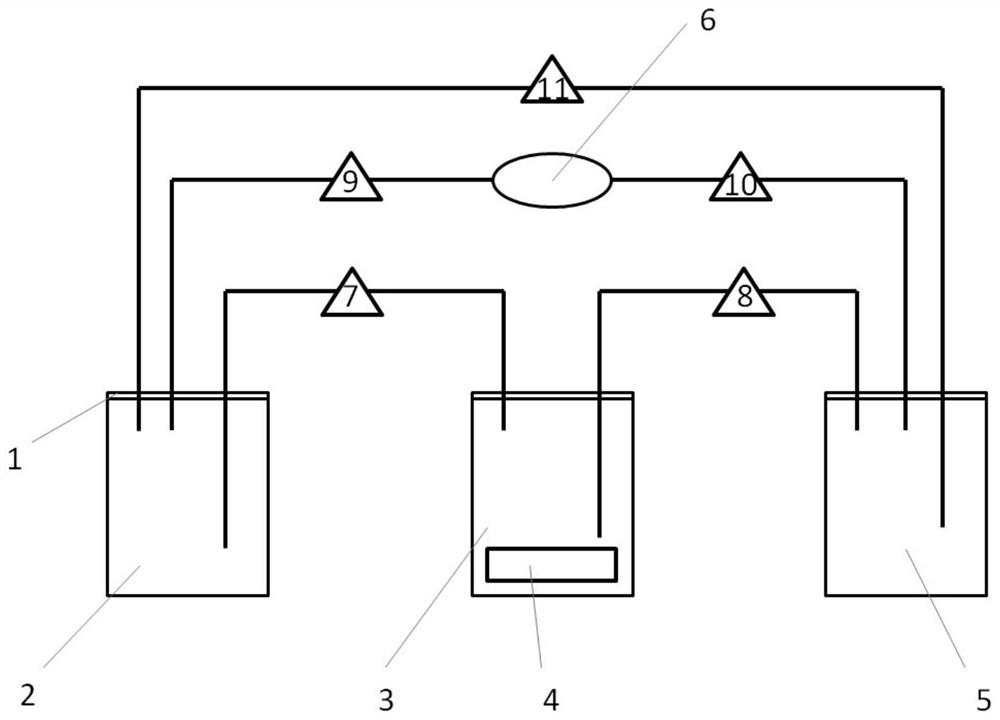

[0019] 2) Connect the air pump 6, the first solution cup 2, the second solution cup 5, the corrosion cup 3, the conduit and the air valve together as shown in the figure.

[0020] 3) Put the corrosion solution into the first solution cup 2, put the microporous plate 6 into the corrosion cup 3, and seal all the joints well to ensure no air leakage.

[0021] 4) Perform solution replacement according to certain steps, repeat several times, so that the corrosion solution exists in the corrosion cup 3 and the air pressure is as low as possible.

[0022] 5) Open the corrosion cup 3, put it together with the corrosion solution in it and the microporous plate 6 under the condition of specified temperature and corrode for a certain period of time.

[0023] The technical solution of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com