Metallographic etching methods for high temperature alloy

A high-temperature alloy and metallographic corrosion technology, applied in the field of alloy corrosion, can solve problems such as high concentration and ecological environment pollution, and achieve the effect of reducing pollution, good corrosion effect, and significant production practice significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

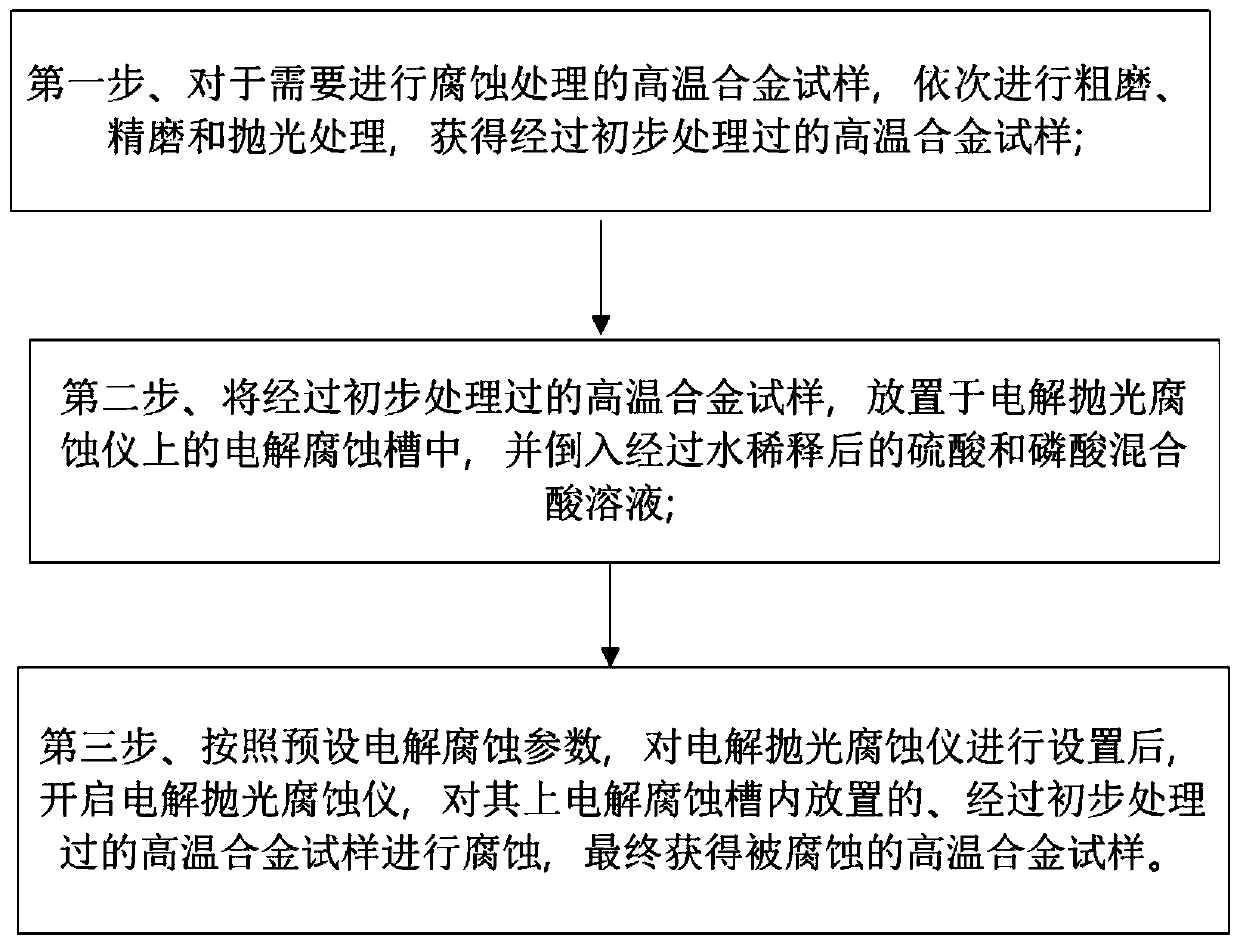

[0052] The first step, the preparation of superalloy samples: Use a grinder or wire cutting to cut a cylindrical sample of φ8×15, follow the conventional rough grinding → fine grinding → polishing metallographic treatment process, and place it on the electrolytic polishing corrosion instrument for electrolytic corrosion. In the electrolytic corrosion tank of the platform.

[0053] The second step, electrolyte configuration and addition: Dilute the mixed acid solution of sulfuric acid and phosphoric acid (mass ratio 1:1.2) with distilled water 20 times, and then pour it into the electrolytic corrosion tank.

[0054] The third step, electrolytic corrosion parameter adjustment: adjust the corrosion voltage of the electrolytic polishing corrosion instrument to 3V, and the corrosion time is 15 minutes;

[0055] The fourth step, starting up and corroding: fix the sample, turn on the pump, and then turn on the power switch to corrode the sample;

[0056] Step 5: Remove the sample fo...

Embodiment 2

[0061] The first step, the preparation of superalloy samples: Use a grinder or wire cutting to cut a cylindrical sample of φ15×15, follow the conventional rough grinding → fine grinding → polishing metallographic treatment process, and place it on the electrolytic polishing corrosion instrument for electrolytic corrosion. In the electrolytic corrosion tank of the platform.

[0062] The second step, electrolyte configuration and addition: Dilute the mixed acid solution of sulfuric acid and phosphoric acid (1:1.2 by mass) with distilled water 10 times, and then pour it into the electrolytic corrosion tank.

[0063] The third step, electrolytic corrosion parameter adjustment: adjust the corrosion voltage of the electrolytic polishing corrosion instrument to 5V, and the corrosion time is 1min;

[0064] The fourth step, starting up and corroding: fix the sample, turn on the pump, and then turn on the power switch to corrode the sample;

[0065] Step 5: Remove the sample for cleani...

Embodiment 3

[0070] The first step, the preparation of superalloy samples: use a grinder or wire cutting to cut a cylindrical sample of φ25×15, follow the conventional rough grinding → fine grinding → polishing metallographic treatment process, and place the electrolytic corrosion load on the electrolytic polishing corrosion instrument In the electrolytic corrosion tank of the platform.

[0071] The second step, electrolyte configuration and addition: Dilute the mixed acid solution of sulfuric acid and phosphoric acid (mass ratio 1:1.2) 5 times with distilled water, and then pour it into the electrolytic corrosion tank.

[0072] The third step, electrolytic corrosion parameter adjustment: adjust the corrosion voltage of the electrolytic polishing corrosion instrument to 1V, and the corrosion time is 10 minutes;

[0073] The fourth step, starting up and corroding: fix the sample, turn on the pump, and then turn on the power switch to corrode the sample;

[0074] Step 5: Remove the sample f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com