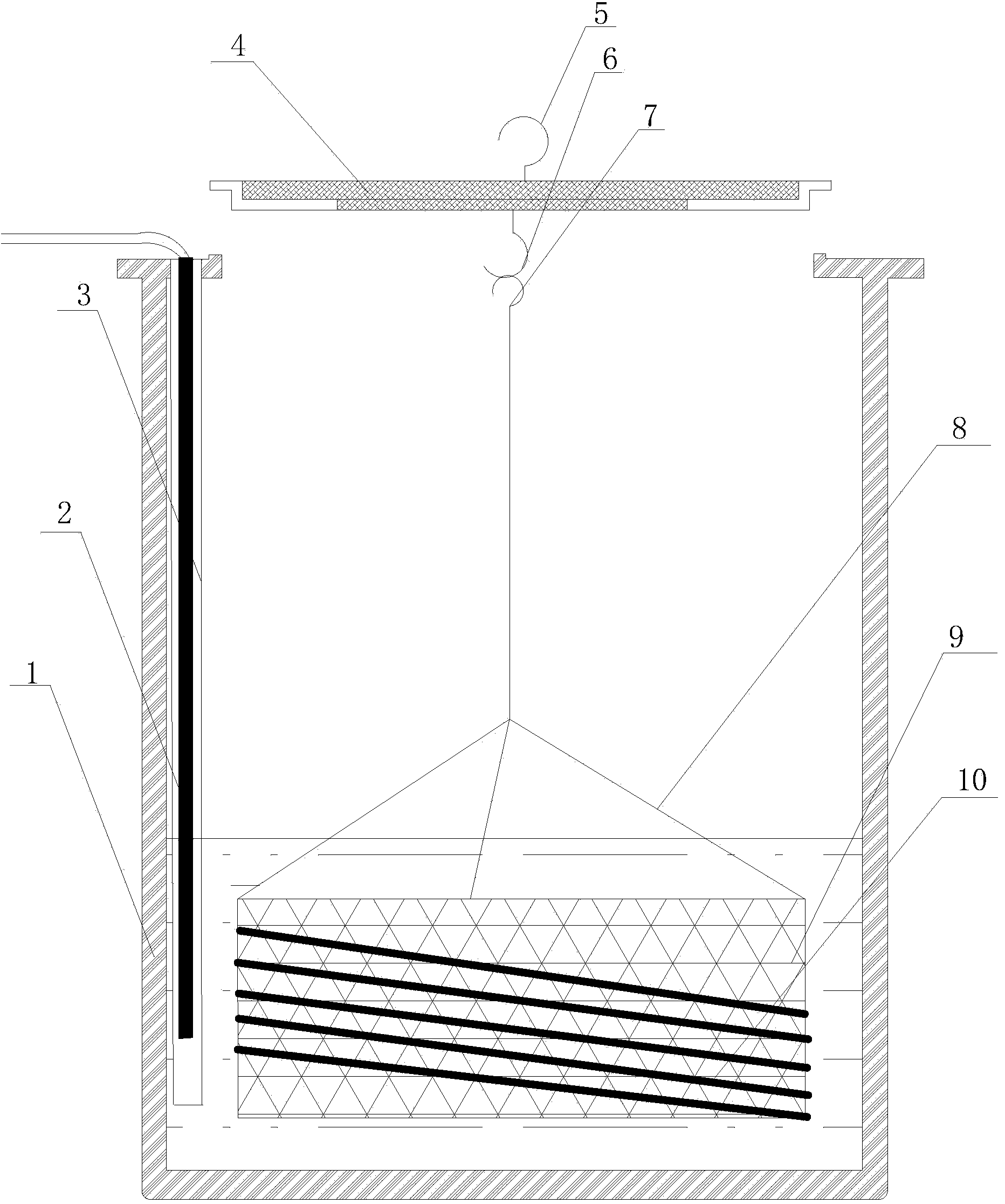

Corrosion method and device for silicon carbide wafers

A silicon carbide crystal and wafer technology, applied in chemical instruments and methods, crystal growth, post-processing and other directions, can solve the problems of low utilization rate of energy and etchant, inability to remove etchant in time, insufficient safety protection, etc., to improve energy and etchant. Utilization rate, excellent corrosion effect, the effect of increasing the actual corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

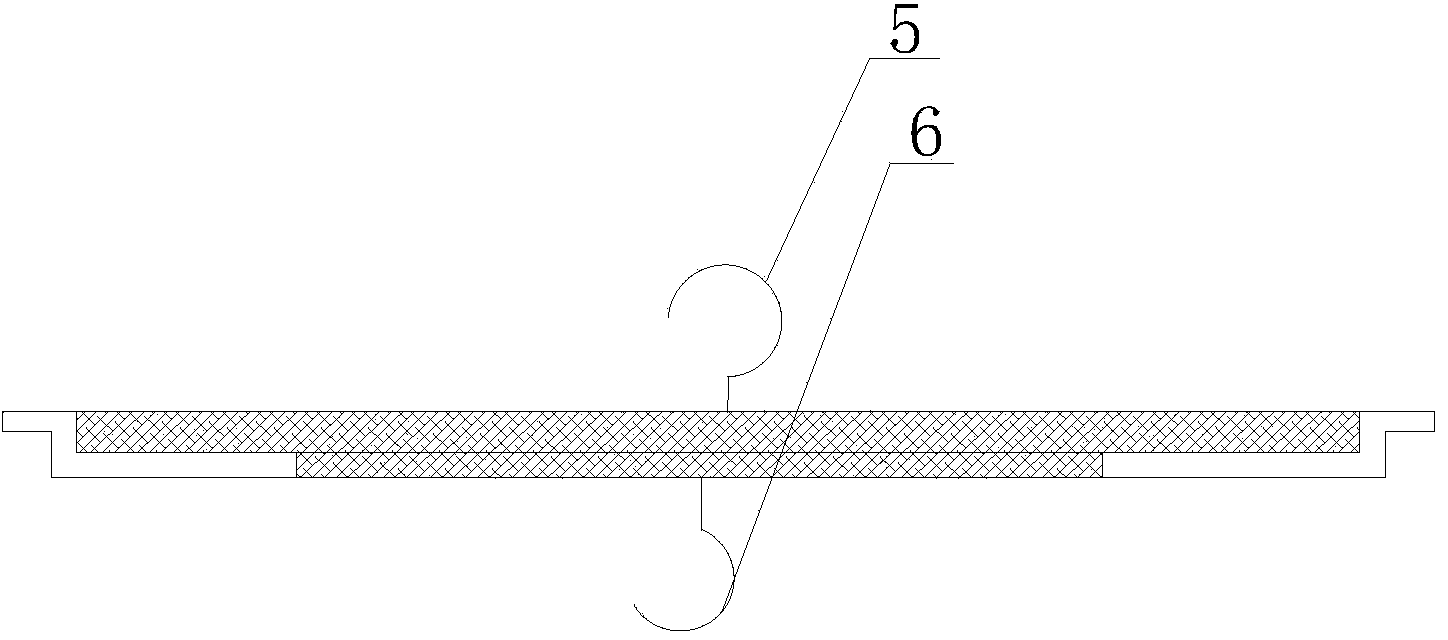

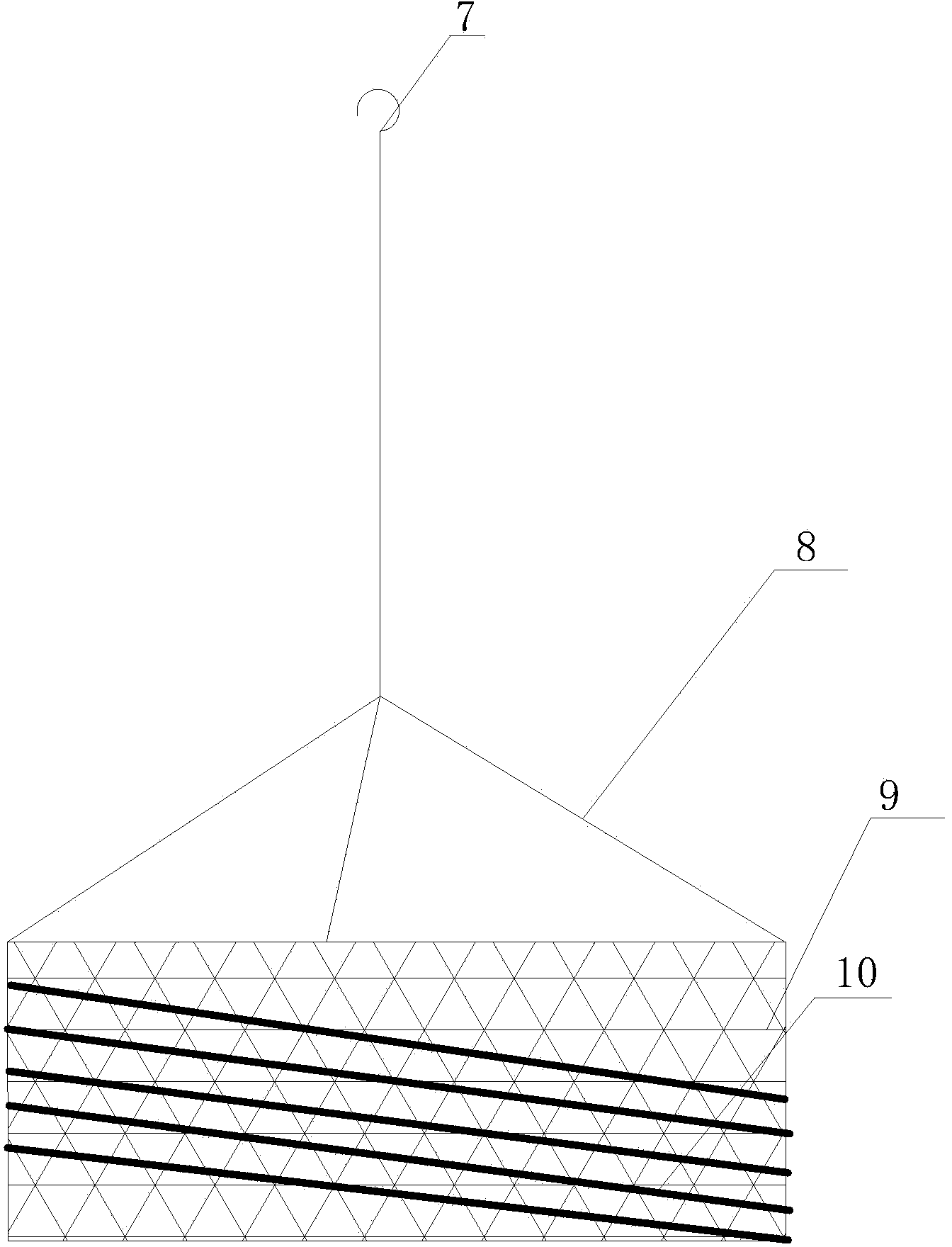

Method used

Image

Examples

Embodiment 1

[0037] A corrosive agent consisting of three components of KOH, NaOH and fluorine salts,

[0038]Wherein said fluorine salt is selected KF;

[0039] The molar fraction of KF in the etchant is 1%; meanwhile, the molar ratio of KOH and NaOH in the etchant is 1:1.

Embodiment 2

[0041] A corrosive agent consisting of three components of KOH, NaOH and fluorine salts,

[0042] Wherein said fluorine salt is selected the mol ratio of KF and NaF as 1:1 mixture;

[0043] The mole fraction of the mixture of KF and NaF in the etchant is 50%; at the same time, the molar ratio of KOH and NaOH in the etchant is 1:1.

Embodiment 3

[0045] A corrosive agent consisting of three components of KOH, NaOH and fluorine salts,

[0046] Wherein the fluoride salt is selected from NaF;

[0047] The molar fraction of NaF in the etchant is 10%; meanwhile, the molar ratio of KOH and NaOH in the etchant is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com