Gallium oxide wafer surface treatment method

A surface treatment, gallium oxide technology, applied in chemical instruments and methods, post-treatment, post-treatment details, etc., can solve the problems of low corrosion removal rate, high corrosion temperature, long corrosion time, etc., and achieve high corrosion efficiency and corrosion temperature. Low, internal stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

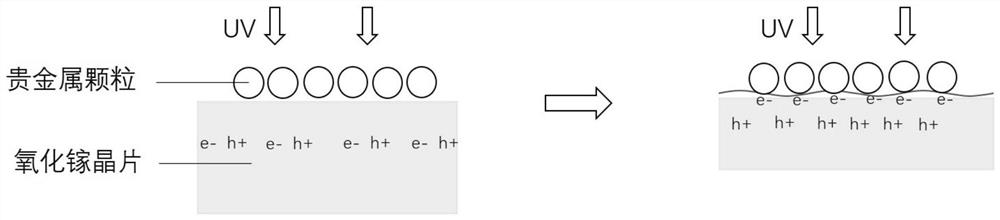

[0047] This embodiment provides a gallium oxide wafer surface treatment method, including:

[0048] 1) After the gallium oxide wafer is cleaned to remove organic matter and metal particles on the surface, it is blown dry with nitrogen;

[0049] 2) Put the gallium oxide wafer into the mixed solution of silver nitrate and hydrofluoric acid for 60s to deposit a certain amount of Ag particles; after the silver plating is finished, wash it with deionized water and enter the next metal-assisted corrosion process;

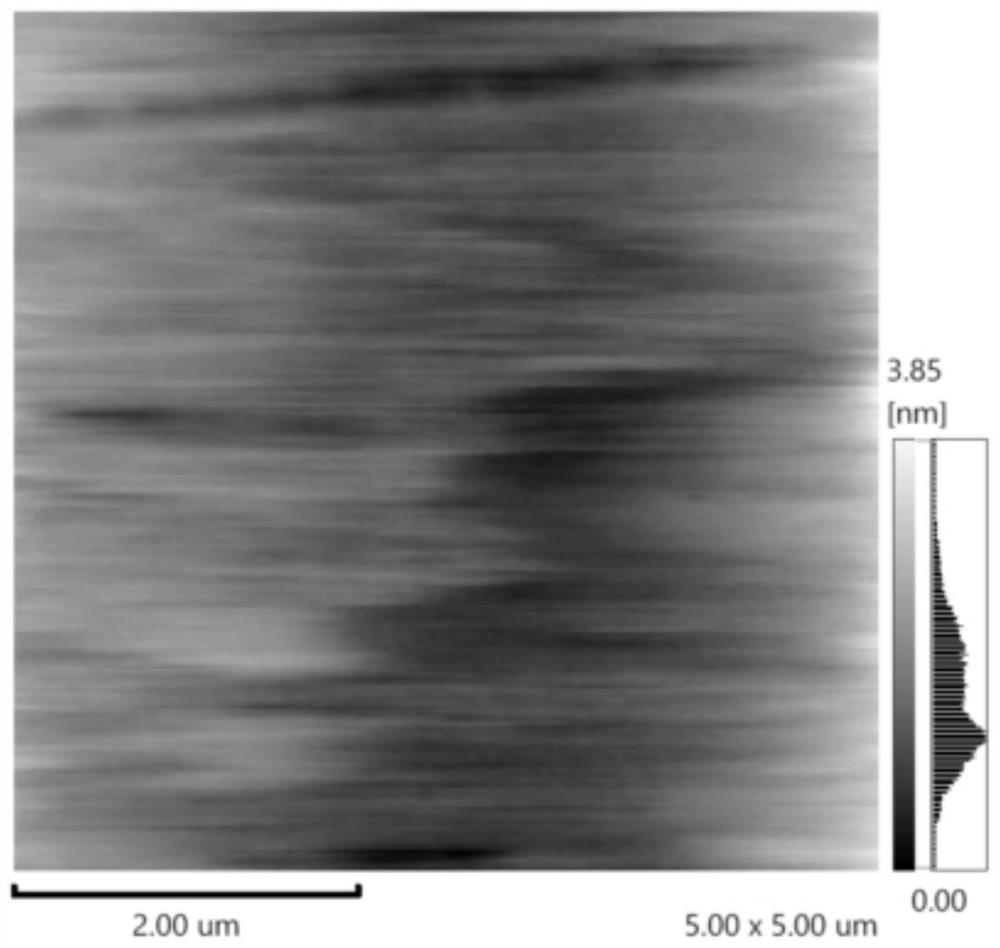

[0050] 3) Each component of the corrosion solution is hydrofluoric acid 12wt.%, the oxidant is sodium persulfate 0.005wt.%, the surfactant is ethanol 0.02wt.%. The wafer is irradiated, and the distance between the light source and the wafer is 6cm;

[0051] 4) Put the gallium oxide wafer after etching into concentrated nitric acid solution and let it stand for 0.5 h; finally, take out the wafer from which the metal particles have been removed, rinse it with deionized wat...

Embodiment 2

[0054] This embodiment provides a gallium oxide wafer surface treatment method, including:

[0055] 1) After the gallium oxide wafer is cleaned to remove organic matter and metal particles on the surface, it is blown dry with nitrogen;

[0056] 2) Deposit Au particles with a thickness of 2-5nm on the surface of the cleaned wafer by vacuum evaporation; after the gold spraying is completed, enter the next step of metal-assisted corrosion process;

[0057] 3) Each component of the corrosion solution is hydrofluoric acid 12wt.%, the oxidant is sodium persulfate 0.005wt.%, the surfactant is ethanol 0.02wt.%. The wafer is irradiated, and the distance between the light source and the wafer is 6cm;

[0058] 4) Put the gallium oxide wafer after etching into the aqua regia solution and let it stand for 1 hour; finally, take out the wafer from which the metal particles have been removed, rinse it with deionized water, and dry it with nitrogen gas.

[0059] At room temperature, the corr...

Embodiment 3

[0061] This embodiment provides a gallium oxide wafer surface treatment method, including:

[0062] 1) After the gallium oxide wafer is cleaned to remove organic matter and metal particles on the surface, it is blown dry with nitrogen;

[0063] 2) Put the wafer into the mixed solution of silver nitrate and hydrofluoric acid for 60s to deposit a certain amount of Ag particles; after the silver plating is finished, rinse with deionized water and enter the next metal-assisted corrosion process;

[0064] 3) Each component of the corrosion solution is 12wt.% of hydrofluoric acid, 15wt.% of hydrogen peroxide as the oxidizing agent, 0.02wt.% of ethanol as the surfactant, and the ultraviolet lamp with a power of 120W and a wavelength of 254nm is used for the corrosion of the corrosive liquid. The wafer is irradiated, and the distance between the light source and the wafer is 6cm;

[0065] 4) Put the gallium oxide wafer after etching into concentrated nitric acid solution and let it s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com