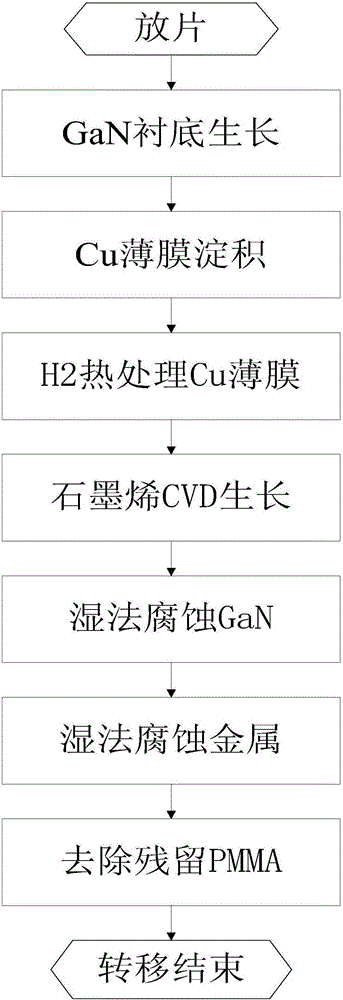

Chemical etching transfer method for CVD epitaxial growth of graphene based on Gan substrate

A transfer method and epitaxial growth technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of poor corrosion effect, degradation of graphene electrical properties, increase of corrosion time, etc., and reduce the corrosion temperature , to avoid adverse effects, to reduce the effect of corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

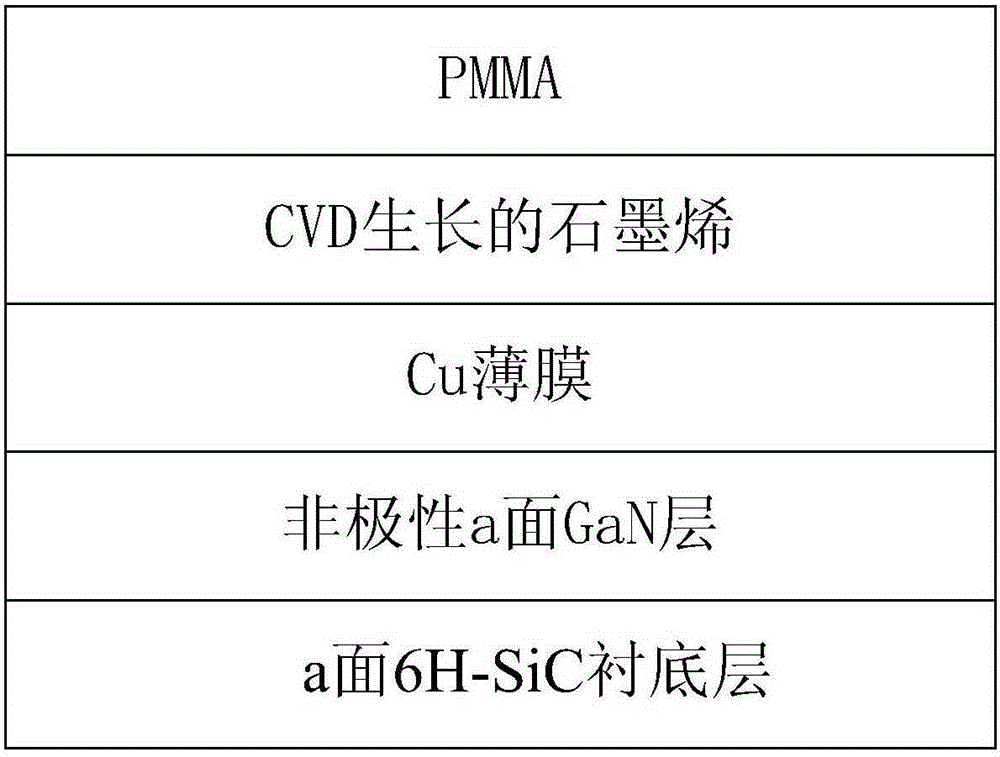

[0025] Step 1, growing a GaN substrate.

[0026] Place the a-side silicon carbide 6H-SiC substrate in the metal organic chemical vapor deposition MOCVD reaction chamber, and pass the mixed gas of gallium source and ammonia gas into the reaction chamber, the flow rate of gallium source is 50 μmol / min, and the flow rate of ammonia gas is 1000 sccm , continued for 1 hour, and grew an a-plane GaN substrate with a thickness of 1 μm.

[0027] Step 2, Cu film deposition and annealing treatment.

[0028] Vacuumize the reaction chamber to ensure that the air pressure is not higher than 10 -6 Under the condition of Torr, a Cu film with a thickness of 1 μm was deposited on the GaN substrate by electron beam evaporation, and H2 with a flow rate of 1 sccm was introduced into the reaction chamber, and the temperature in the reaction chamber was raised to 900 ° C, and the deposited Cu film was thermally annealed. The annealing time is 20min.

[0029] Step 3, growing graphene.

[0030] It...

Embodiment 2

[0045] Step A, growing a GaN substrate.

[0046] Place the a-side silicon carbide 6H-SiC substrate in the metal organic chemical vapor deposition MOCVD reaction chamber, and feed the mixed gas of gallium source and ammonia gas into the reaction chamber. The flow rate of gallium source is 100 μmol / min, and the flow rate of ammonia gas is 2000 sccm , continued for 40 hours, and grew an a-plane GaN substrate with a thickness of 2 μm.

[0047] Step B, Cu film deposition and annealing treatment.

[0048] Vacuumize the reaction chamber to ensure that the air pressure is not higher than 10 -6 Under the condition of Torr, electron beam evaporation deposits a Cu film with a thickness of 2 μm on the GaN substrate, feeds H2 with a flow rate of 10 sccm into the reaction chamber, raises the temperature in the reaction chamber to 950 ° C, and performs thermal annealing on the deposited Cu film. The annealing time is 20min.

[0049] Step C, growing graphene.

[0050] It is 50sccm H that ...

Embodiment 3

[0065] Step 1, growing a GaN substrate.

[0066] Place the a-side silicon carbide 6H-SiC substrate in the metal organic chemical vapor deposition MOCVD reaction chamber, feed the mixed gas of gallium source and ammonia gas into the reaction chamber, the flow rate of gallium source is 150 μmol / min, and the flow rate of ammonia gas is 3000 sccm , continued for 0.5 hours, and grew an a-plane GaN substrate with a thickness of 1.5 μm.

[0067] Step 2, Cu film deposition and annealing treatment.

[0068] Vacuumize the reaction chamber to ensure that the air pressure is not higher than 10 -6 Under the condition of Torr, electron beam evaporation deposits a Cu film with a thickness of 3 μm on the GaN substrate, feeds H2 with a flow rate of 20 sccm into the reaction chamber, raises the temperature in the reaction chamber to 1000 ° C, and performs thermal annealing on the deposited Cu film. The annealing time is 60min.

[0069] Step three, grow graphene.

[0070] It is 100sccm H2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com