Graded dendritic PtCu electro-catalyst and preparation method thereof

A dendritic and cubic technology, applied in the field of hierarchical dendritic PtCu electrocatalysts and its preparation, achieves the effects of high repeatability, simple process and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

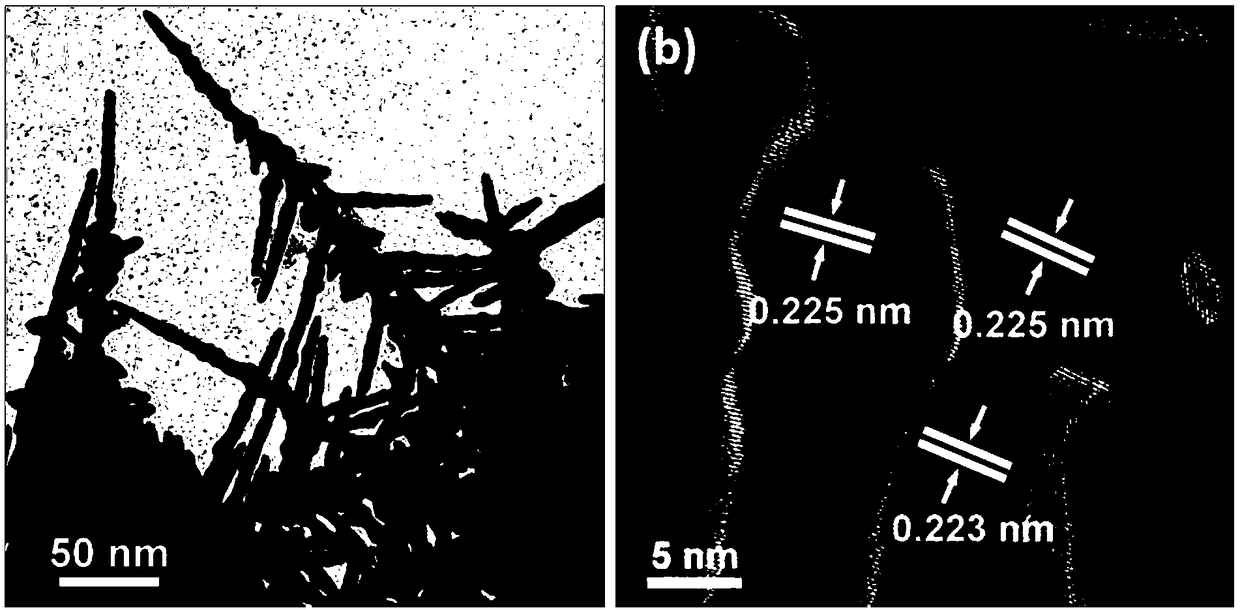

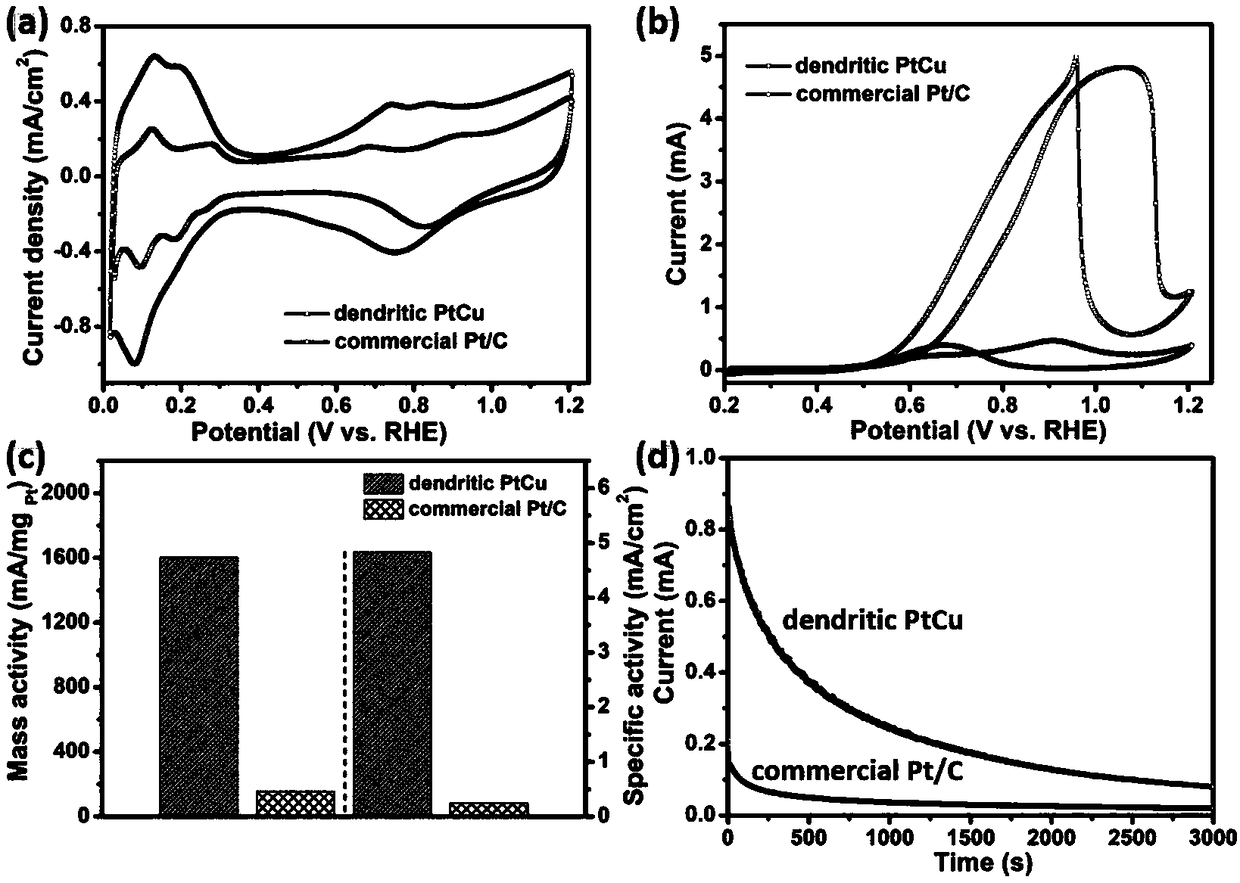

Image

Examples

Embodiment 1

[0041] A hierarchical dendritic PtCu electrocatalyst and a preparation method thereof, comprising the steps of:

[0042] (1) Mix 9 mL of oleylamine with 1 mL of oleic acid solution, and obtain a colorless and clear solution by ultrasonication at 55° C. to obtain a mixed solution of oleylamine and oleic acid;

[0043] (2) Add 0.5 mL of ethylene glycol solution to the mixed solution of oleylamine and oleic acid described in (1), and sonicate at 55°C to a colorless and clear solution;

[0044] (3) Add 8.0 mg of platinum acetylacetonate and 5.2 mg of copper acetylacetonate to the clear mixed solution obtained in (2), and sonicate at 55° C. to a colorless and clear solution;

[0045] (4) The above clarified mixed solution was placed in an oil bath at 170° C. for 12 hours.

[0046] (5) The product is centrifuged and washed with a mixed solution of ethanol and cyclohexane.

[0047] (6) Soak the black product in 5mL concentrated nitric acid solution for 1 day, then centrifuge and wa...

Embodiment 2

[0055] A hierarchical dendritic PtCu electrocatalyst and a preparation method thereof, comprising the steps of:

[0056] (1) Mix 9 mL of oleylamine with 1 mL of oleic acid solution, and obtain a colorless and clear solution by ultrasonication at 55° C. to obtain a mixed solution of oleylamine and oleic acid;

[0057] (2) Add 0.5 mL of ethylene glycol solution to the mixed solution of oleylamine and oleic acid described in (1), and sonicate at 55°C to a colorless and clear solution;

[0058] (3) Add 8.0 mg of platinum acetylacetonate and different contents of copper acetylacetonate to the clarified mixed solution obtained in (2) for comparison. In this example, 10.4 mg and 2.6 mg of copper acetylacetonate are selected, and then ultrasonicated at 55° C. to a colorless clear solution;

[0059] (4) The above clarified mixed solution was placed in an oil bath at 170° C. for 12 hours.

[0060] (5) The product is centrifuged and washed with a mixed solution of ethanol and cyclohexa...

Embodiment 3

[0063] A hierarchical dendritic PtCu electrocatalyst and a preparation method thereof, comprising the steps of:

[0064] (1) Mix different amounts of oleylamine and oleic acid solution. In this example, 8mL oleylamine / 2mL oleic acid and 7mL oleylamine / 3mL oleic acid were respectively selected, and a colorless and clear solution was obtained by ultrasonication at 55°C to obtain oleylamine and oleylamine. Oleic acid mixed solution;

[0065] (2) Add 0.5 mL of ethylene glycol solution to the mixed solution of oleylamine and oleic acid described in (1), and sonicate at 55°C to a colorless and clear solution;

[0066] (3) Add 8.0 mg of platinum acetylacetonate and 5.2 mg of copper acetylacetonate to the clear mixed solution obtained in (2), and sonicate at 55° C. to a colorless and clear solution;

[0067] (4) The above clarified mixed solution was placed in an oil bath at 170° C. for 12 hours.

[0068] (5) The product is centrifuged and washed with a mixed solution of ethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com