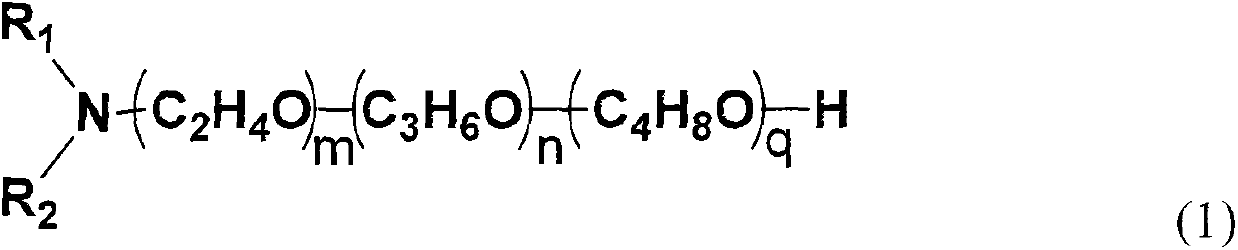

Dialkylene amine polyether and preparation method and application thereof

A technology of dienyl amine polyether and dienyl amine, which is applied in the application field of high molecular polymer synthesis, can solve the problems of difficult performance improvement of polycarboxylate water reducer and single type of polyether macromonomer. , to achieve excellent slump retention performance, high double bond retention rate and easy controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides a method for preparing a dienylamine polyether, comprising the following steps:

[0039] (1) Under negative pressure, add dienyl amine and catalyst to the reactor, fill the reactor with nitrogen to replace the air in the reactor, heat the material in the reactor to 90-100°C, slowly add alkylene oxide to Formation reaction, the reaction temperature is 90-130°C, the reaction pressure is less than 0.5MPa, after adding the alkylene oxide, keep the temperature at 90-130°C for at least 30 minutes, and then cool down to 50-80°C; among them, dienylamine and cyclic The molar ratio of oxyalkane is 1: (2-12).

[0040] (2) Add catalyst to the reactor, then fill the reactor with nitrogen to replace the air in the reactor, vacuumize, heat to 90-100°C, then add alkylene oxide for addition reaction, the reaction temperature is 90-130°C, the reaction The pressure is less than 0.5MPa. After adding the alkylene oxide, keep it warm at ...

Embodiment 1

[0044] Diisobutenylamine polyoxyethylene ether, its preparation method is as follows:

[0045]In the first step, put 125 grams of diisobutenylamine and 1.0 grams of sodium methoxide into a clean and dry 4L reaction kettle under negative pressure as a catalyst, replace the air in the kettle with nitrogen, and heat the material to 90-100°C , stop heating, slowly add ethylene oxide to carry out the addition reaction, the reaction temperature is 95 ~ 120 ℃, the reaction pressure is less than 0.5MPa, the addition of ethylene oxide is 275 grams in total, after adding ethylene oxide, at 95 ~120°C heat preservation reaction for at least 30 minutes, until the pressure in the kettle no longer drops, then lower the temperature and cool to 50~80°C.

[0046] In the second step, the reaction kettle of the first step is evacuated, and 4.8 grams of methanol solution of 50% sodium methylate is added under the condition of negative pressure as a catalyst, and then the air in the nitrogen replac...

Embodiment 2

[0048] Diisobutenylamine polyoxyethylene ether, its preparation method is as follows:

[0049] In the first step, put 125 grams of diisobutenylamine and 1.0 grams of sodium methoxide into a clean and dry 4L reaction kettle under negative pressure as a catalyst, replace the air in the kettle with nitrogen, and heat the material to 90-100°C , stop heating, slowly add ethylene oxide to carry out the addition reaction, the reaction temperature is 95 ~ 120 ℃, the reaction pressure is less than 0.5MPa, the addition of ethylene oxide is 275 grams in total, after adding ethylene oxide, at 95 ~120°C heat preservation reaction for at least 30 minutes, until the pressure in the kettle no longer drops, then lower the temperature and cool to 50~80°C.

[0050] In the second step, the reaction kettle of the first step is evacuated, and 9.0 grams of methanol solution of 50% sodium methylate is added as a catalyst under the condition of negative pressure, and then the air in the nitrogen repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com