Double-phase stainless steel microstructure and sigma mesophase chromatic corrosive and corrosion method

A duplex stainless steel and microstructure technology, which is applied in the field of duplex stainless steel microstructure and σ mesophase color etchant and corrosion, can solve the problem of poor thermal processing performance of duplex stainless steel, easy corrosion of σ phase, easy over-corrosion, etc. problem, to achieve the effect of good erosion effect, simple configuration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

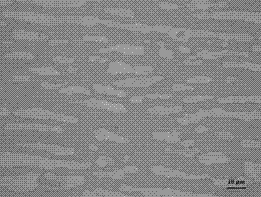

Embodiment 1

[0025] The following part of this example describes a duplex stainless steel microstructure and sigma mesophase color etchant.

[0026] Consists of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, each composition is: potassium metabisulfite 0.3g; hydrochloric acid (mass percentage concentration: 40%) 10ml; nitric acid (mass percentage concentration: 68%) 5ml ; Hydrofluoric acid (mass percentage concentration is 40%) 10ml; deionized water 200ml.

[0027] The following part of this embodiment describes a microstructure of a duplex stainless steel and a configuration method of a sigma mesophase color etchant.

[0028] Prepare the corrosive agent in the following order: first weigh 0.3g of potassium metabisulfite, measure hydrochloric acid (mass percentage concentration is 40%) 10ml, nitric acid (mass percentage concentration is 68%) 5ml and hydrofluoric acid (mass percentage concentration 40%) 10ml, and then measure 200ml of deionized water, mix it i...

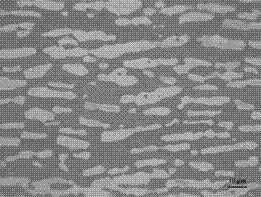

Embodiment 2

[0034] The following part of this example describes a duplex stainless steel microstructure and sigma mesophase color etchant.

[0035] This metallographic etching agent is made of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, and each composition is respectively: potassium metabisulfite 0.5g; Hydrochloric acid (mass percentage concentration is 40%) 15ml; Nitric acid (mass percentage concentration 68%) 10ml; hydrofluoric acid (mass percentage concentration 40%) 10ml; deionized water 200ml.

[0036] The following part of this embodiment describes a microstructure of a duplex stainless steel and a configuration method of a sigma mesophase color etchant.

[0037] Prepare the corrosive agent in the following order: first weigh 0.5g of potassium metabisulfite, measure hydrochloric acid (mass percentage concentration is 40%) 15ml, nitric acid (mass percentage concentration is 68%) 10ml and hydrofluoric acid (mass percentage concentration 40%) 10ml, a...

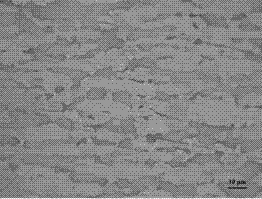

Embodiment 3

[0043] The following part of this example describes a duplex stainless steel microstructure and sigma mesophase color etchant.

[0044] This metallographic etching agent is made of hydrochloric acid, nitric acid, potassium metabisulfite and deionized water, and each composition is respectively: potassium metabisulfite 0.5g; Hydrochloric acid (mass percentage concentration is 40%) 10ml; Nitric acid (mass percentage concentration 68%) 10ml; hydrofluoric acid (mass percentage concentration 40%) 10ml; deionized water 150ml.

[0045] The following part of this embodiment describes a microstructure of a duplex stainless steel and a configuration method of a sigma mesophase color etchant.

[0046] Prepare the corrosive agent in the following order: first weigh 0.5g of potassium metabisulfite, measure hydrochloric acid (mass percentage concentration is 40%) 10ml, nitric acid (mass percentage concentration is 68%) 10ml and hydrofluoric acid (mass percentage concentration 40%) 10ml, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com