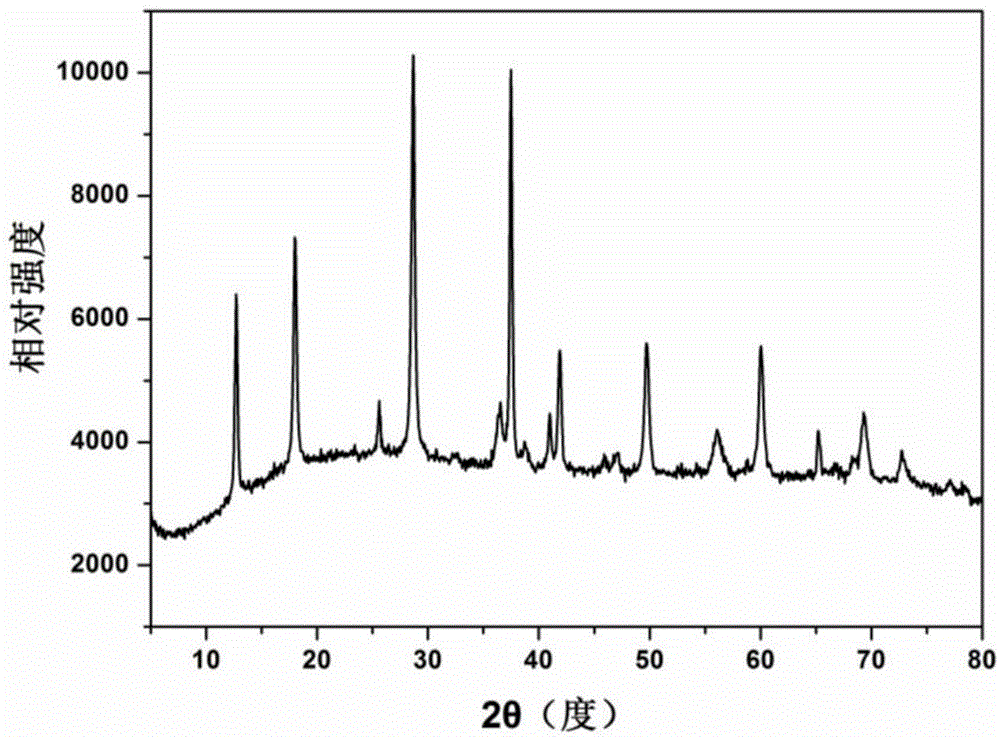

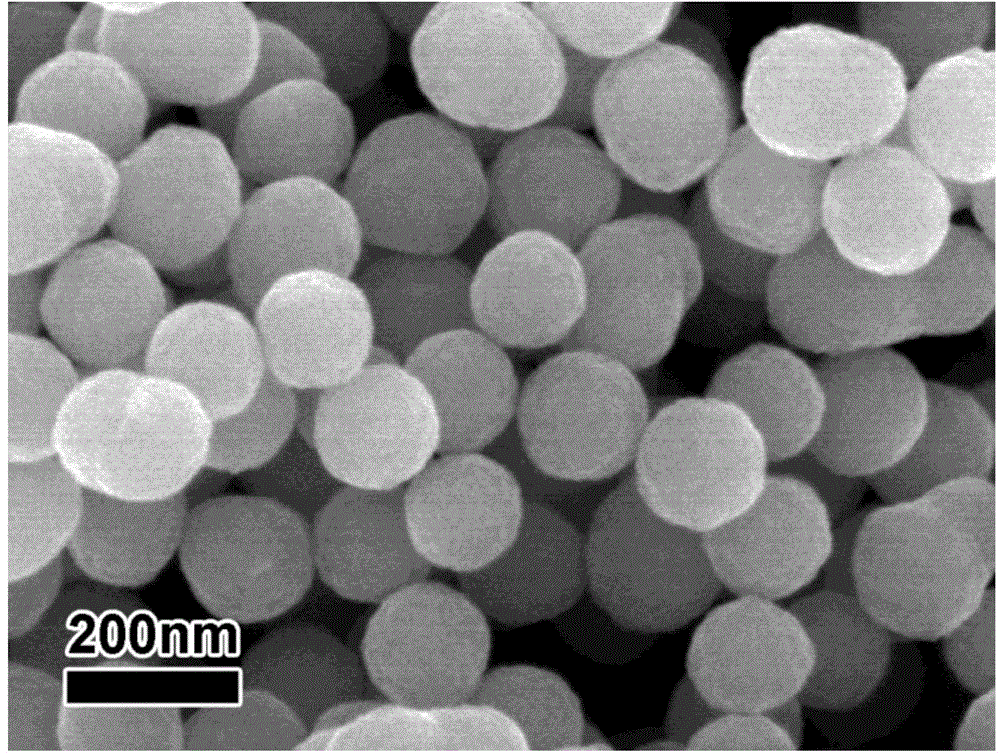

Synthesis method and use of monodispersed KMn8O16 nanospheres

A synthesis method, nanosphere technology, applied in the direction of nanotechnology, nanotechnology, manganese oxide/manganese hydroxide, etc., can solve the problems of unfavorable large-scale application, high temperature required for reaction, long time, etc., and achieve outstanding thermal stability , Safe and stable reaction, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of monodisperse potassium manganese oxide KMn 8 o 16 The synthetic method of nanosphere, comprises the following steps:

[0038] (1) Weigh 0.003mol (0.474g) of potassium permanganate, 0.015mol (1.185g) of ammonium bicarbonate and 0.1g of polyvinylpyrrolidone (K29) into 35mL of deionized water and stir for 30min to obtain a uniform purple transparent solution;

[0039] (2) Add 70ml of isopropanol to the purple transparent solution prepared in step (1), stir for 15min to form a uniform mixed solution;

[0040] (3) Transfer the homogeneously mixed solution obtained in step (2) into a 500mL beaker, cover the beaker with plastic wrap (there is a gap between the plastic wrap and the mouth of the beaker), and stir on an oil bath (rotating speed is 1200r / min ), heated up from room temperature to 80°C, then reacted at a constant temperature of 80°C for 5h, and then cooled naturally to obtain a brown-black precipitate;

[0041] (4) Place the obtained brown-black precipi...

Embodiment 2

[0046] A kind of monodisperse potassium manganese oxide KMn 8 o 16 The synthetic method of nanosphere, comprises the following steps:

[0047] (1) Weigh 0.003mol (0.474g) of potassium permanganate, 0.015mol (1.185g) of ammonium bicarbonate and 0.1g of polyvinylpyrrolidone (K29) into 50mL of deionized water and stir for 30min to obtain a uniform purple transparent solution ;

[0048] (2) Add 70ml of isopropanol to the purple transparent solution prepared in step (1), and stir for 15 minutes to form a uniform mixed solution.

[0049] (3) Transfer the homogeneously mixed solution obtained in step (2) into a 500mL beaker, cover the beaker with plastic wrap (there is a gap between the plastic wrap and the mouth of the beaker), and stir on an oil bath (rotating speed is 1200r / min ), heated up from room temperature to 80°C, then reacted at a constant temperature of 80°C for 5h, and then cooled naturally to obtain a brown-black precipitate;

[0050] (4) Place the obtained brown-bl...

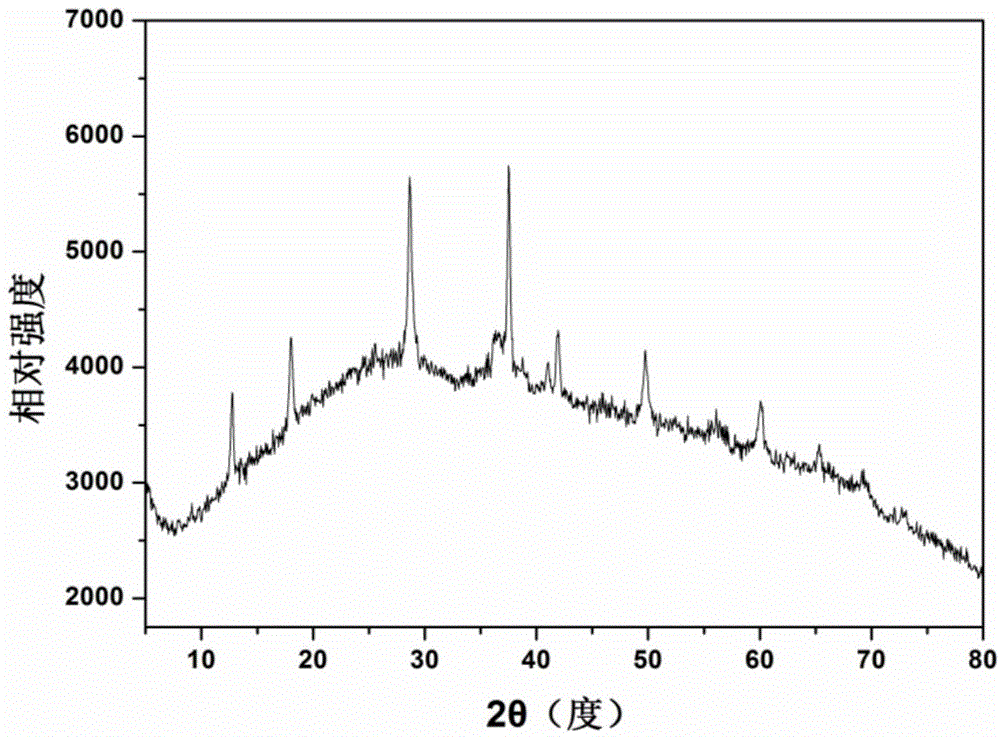

Embodiment 3

[0055] A kind of monodisperse potassium manganese oxide KMn 8 o 16 The synthetic method of nanosphere, comprises the following steps:

[0056] (1) Weigh 0.003mol (0.474g) potassium permanganate, 0.015mol (1.185g) ammonium bicarbonate and 0.1g polyvinylpyrrolidone (K32) into 35mL deionized water, stir for 30min to obtain a uniform purple transparent solution ;

[0057] (2) Add 70ml of isopropanol to the purple transparent solution prepared in step (1), and stir for 15 minutes to form a uniform mixed solution.

[0058] (3) Transfer the homogeneously mixed solution obtained in step (2) into a 500mL beaker, cover the beaker with plastic wrap (there is a gap between the plastic wrap and the mouth of the beaker), and stir on an oil bath (rotating speed is 1200r / min ), heated from room temperature to 60°C, then reacted at a constant temperature of 60°C for 5h, and then cooled naturally to obtain a brownish-black precipitate;

[0059] (4) Place the obtained brown-black precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com